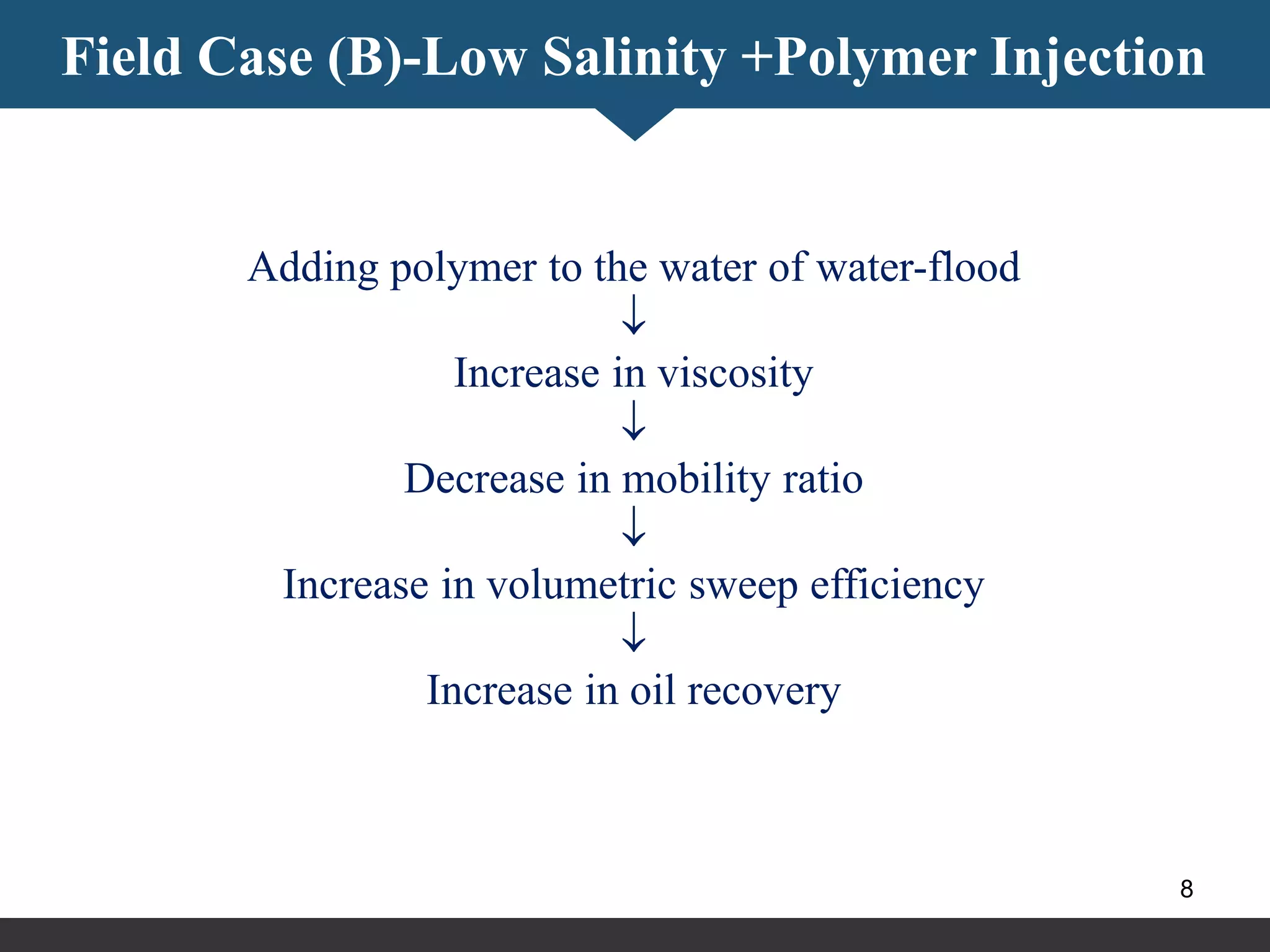

The document discusses Eni's experience with low salinity water injection as an enhanced oil recovery (EOR) technique. It outlines the benefits of reducing injection water salinity, which improves rock wettability and oil recovery, and presents field cases demonstrating the effectiveness of this method. Additionally, combining low salinity with polymer injection is highlighted as the most efficient approach, yielding significant increases in oil recovery.