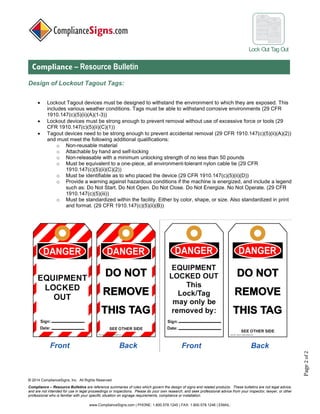

The document outlines the procedures and regulations for Lockout Tagout (LOTO), which are essential for safely shutting down equipment to prevent energy release during maintenance. It emphasizes the responsibilities of employers under OSHA standards to protect workers and the importance of proper training in these procedures. Additionally, it details specifications for the design and use of lockout and tagout devices to ensure safety compliance.