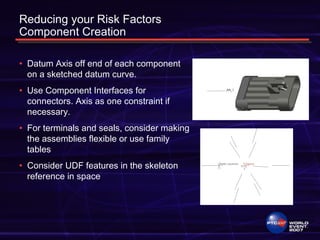

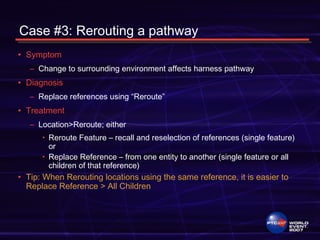

The document discusses strategies for modifying harness assemblies through planned "surgery" rather than emergency "triage". It provides examples of common changes like synchronizing logical references, replacing connector models, rerouting pathways, splitting wires, adjusting bundles, and considerations for downstream deliverables. The key is to apply the best solution through diagnosis, use trained resources with advanced skills, and precisely treat issues while avoiding shortcuts that could cause downstream problems.