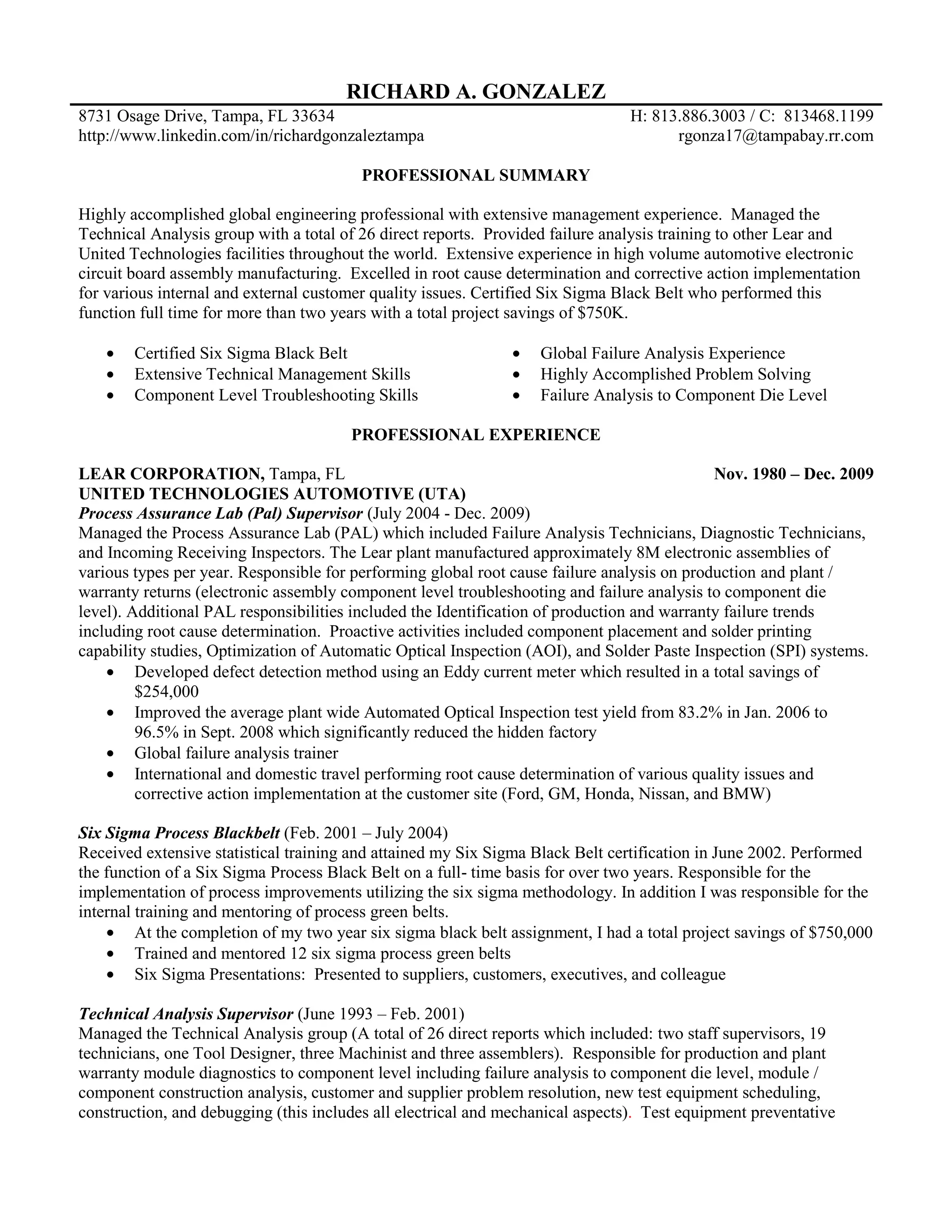

Richard Gonzalez is a highly accomplished global engineering professional with over 29 years of experience at Lear Corporation. He has extensive management and technical experience, including managing a team of 26 employees in the Process Assurance Lab. Gonzalez is a certified Six Sigma Black Belt who led projects saving over $750k. He has global failure analysis experience and provides troubleshooting and problem solving skills.