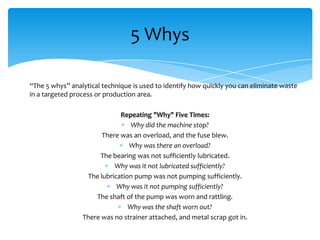

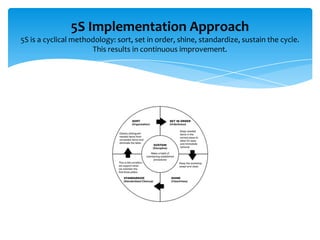

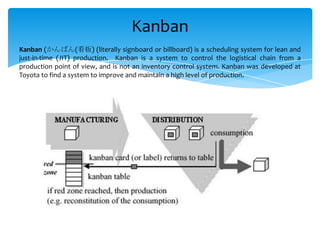

This document summarizes several key lean thinking methods and tools, including Kaizen, 5 Whys, 5S, Kanban, Six Sigma, and 3P. Kaizen focuses on continual small improvements to eliminate waste. The 5 Whys technique is used to identify the root cause of problems. 5S organizes and standardizes the workplace. Kanban controls production flow through a pull system. Six Sigma uses statistical methods to reduce process variation and defects. 3P focuses on designing products and processes with minimal waste from the outset.