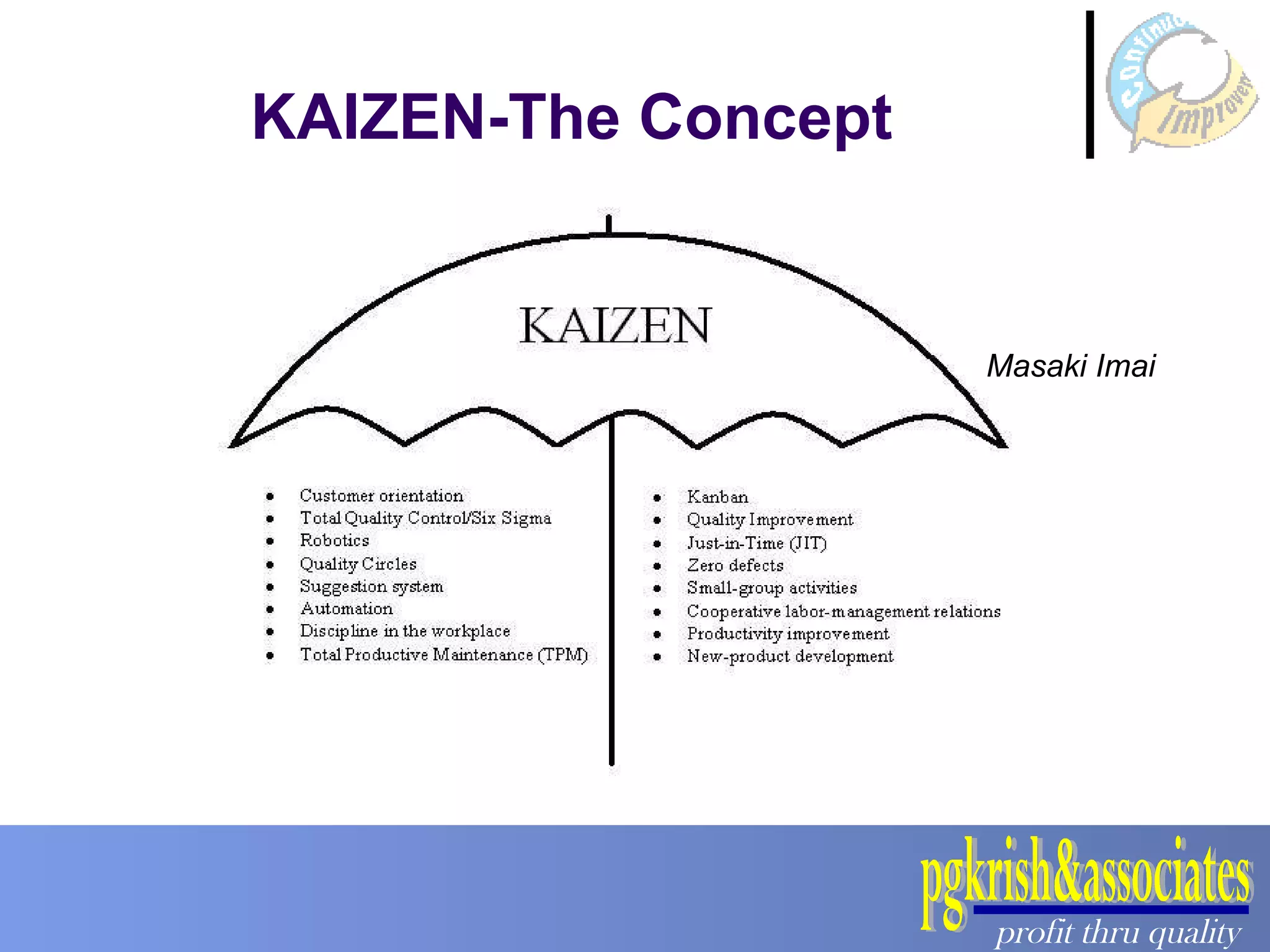

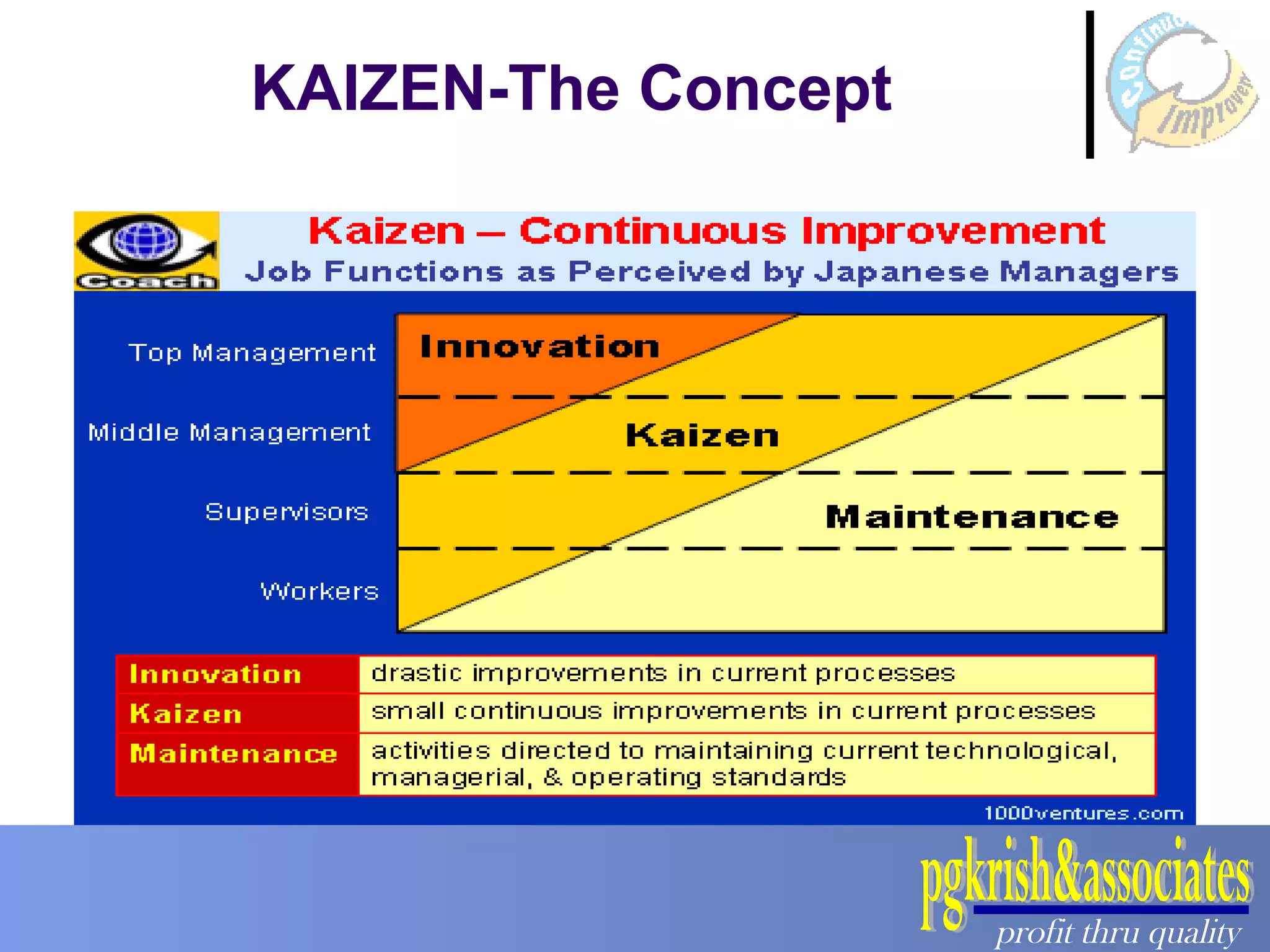

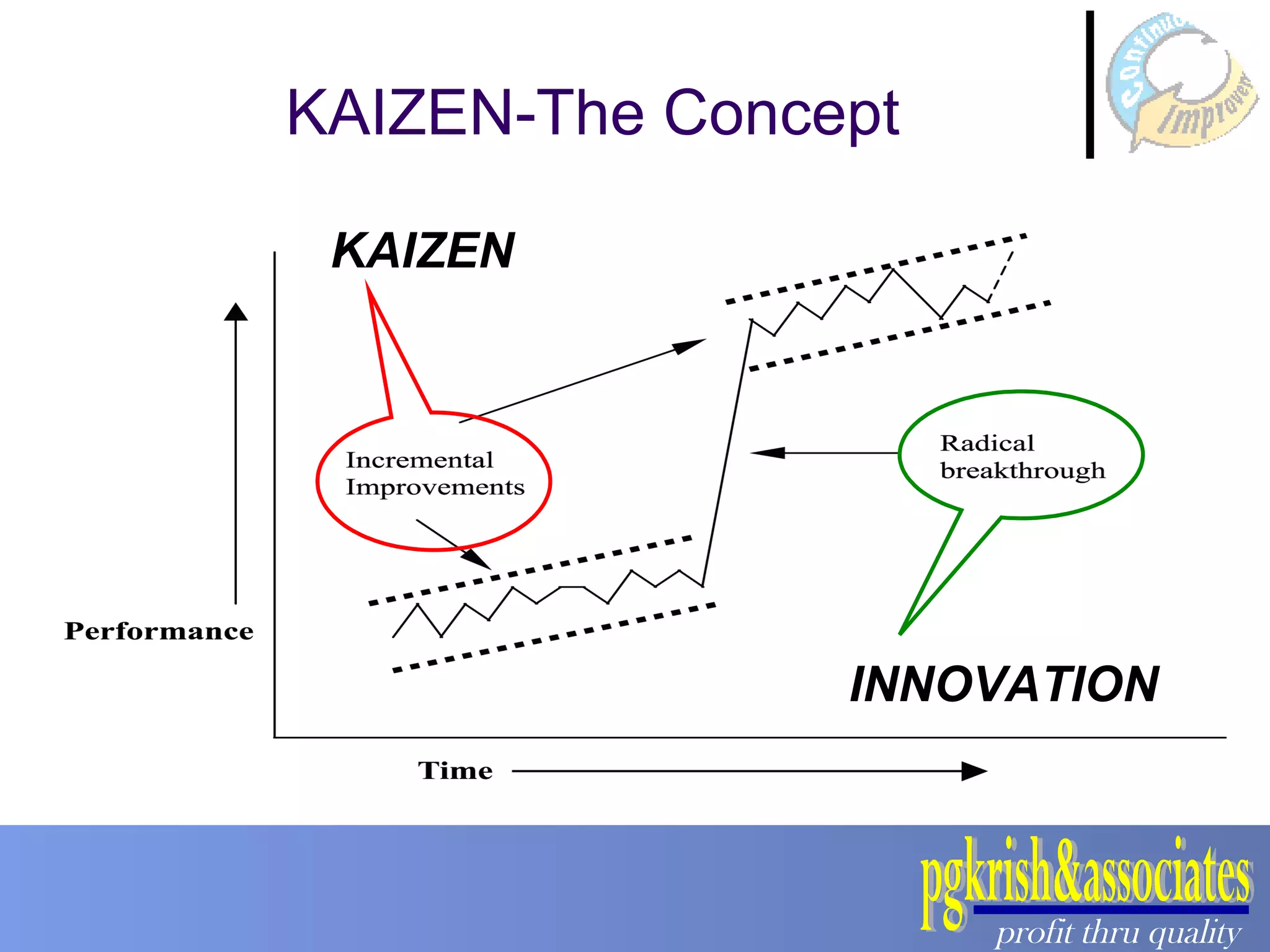

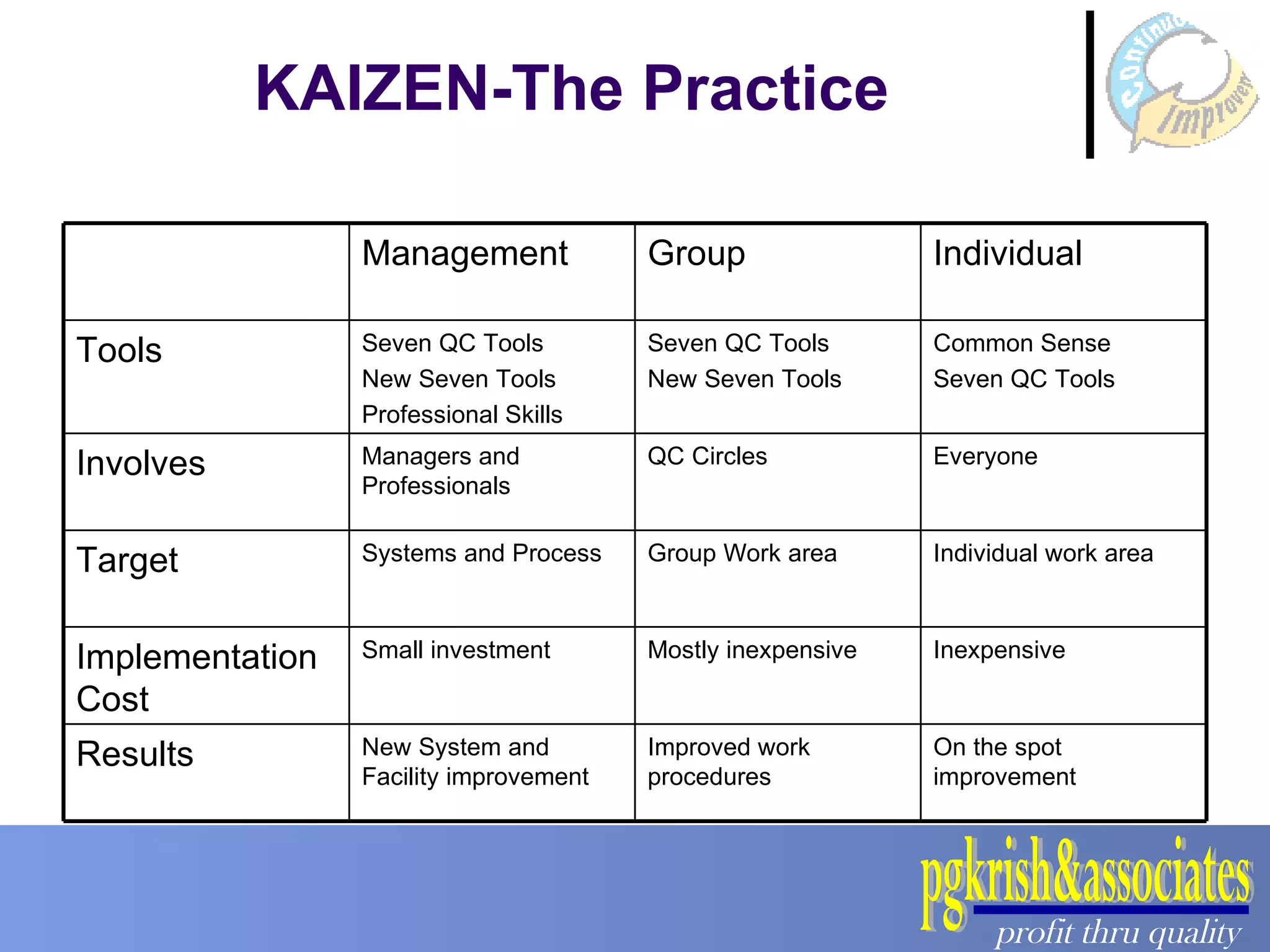

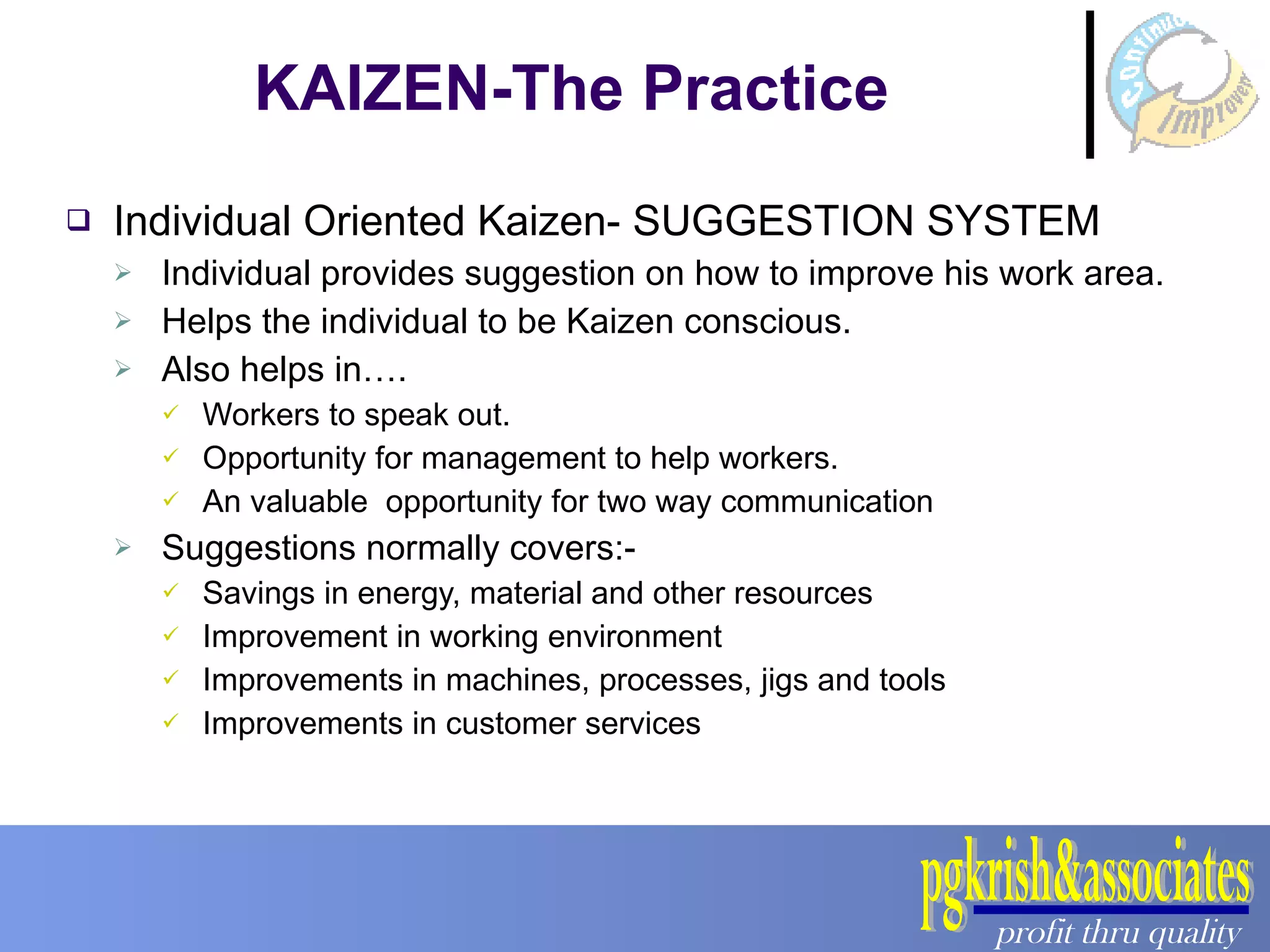

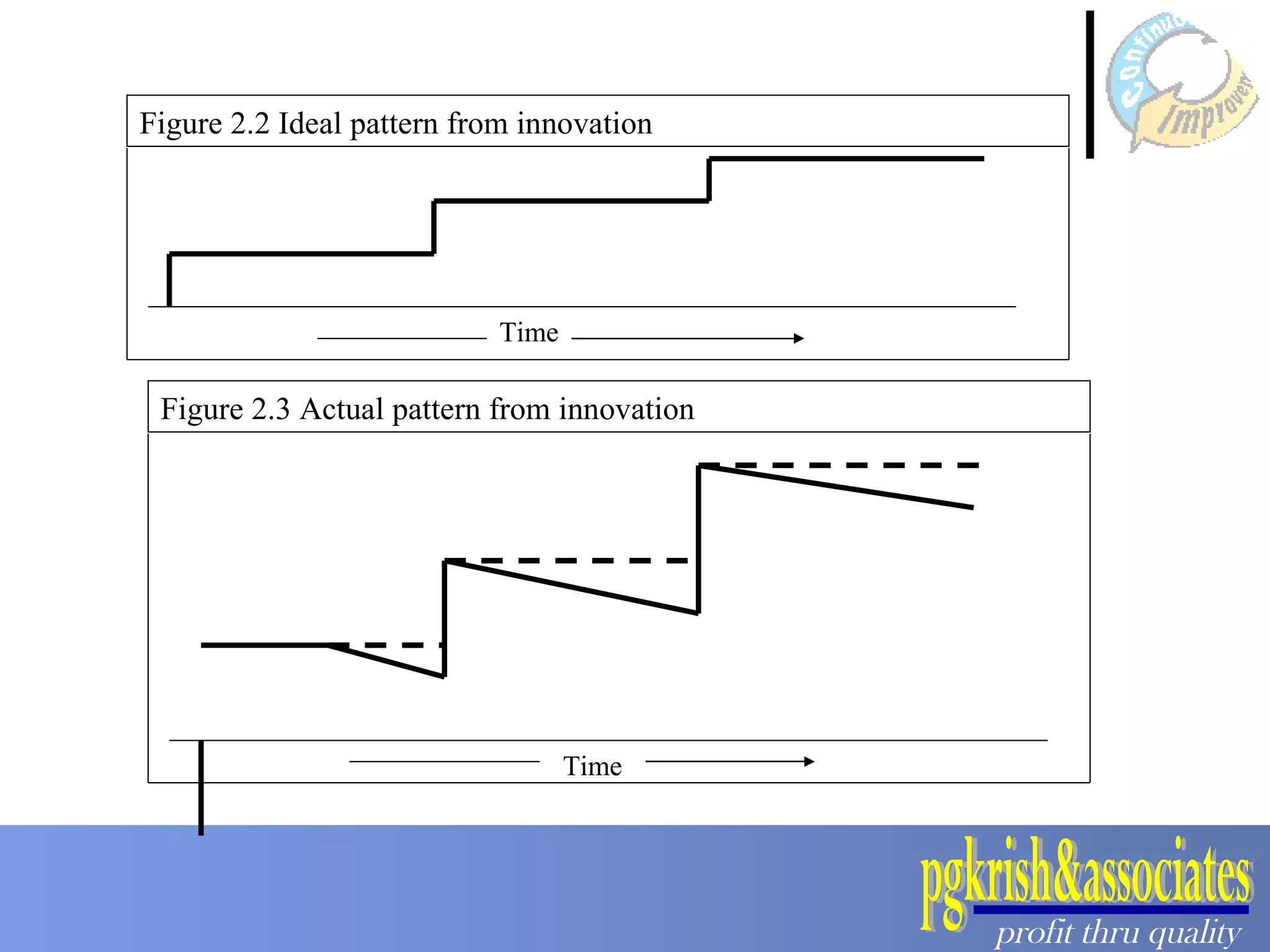

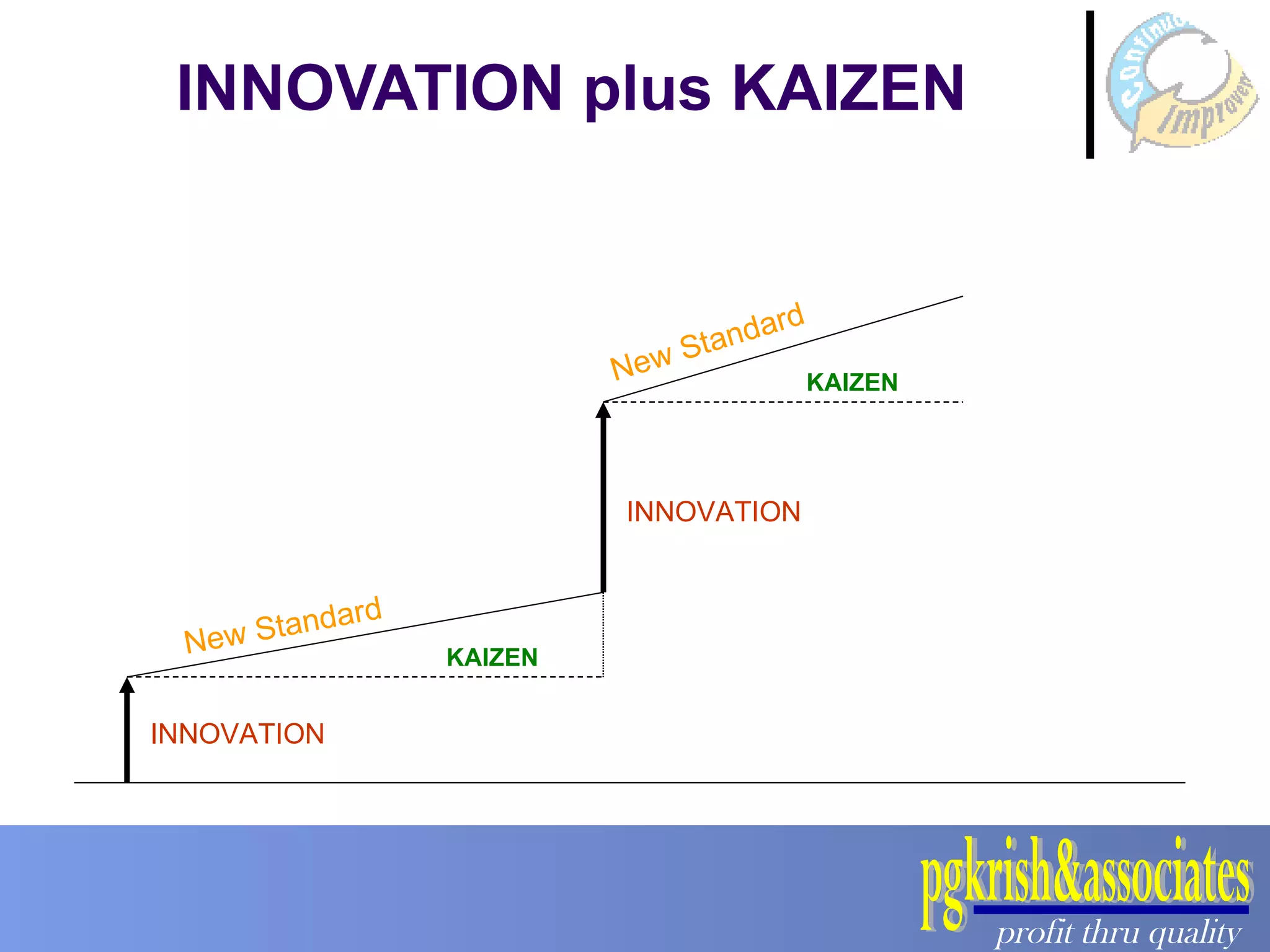

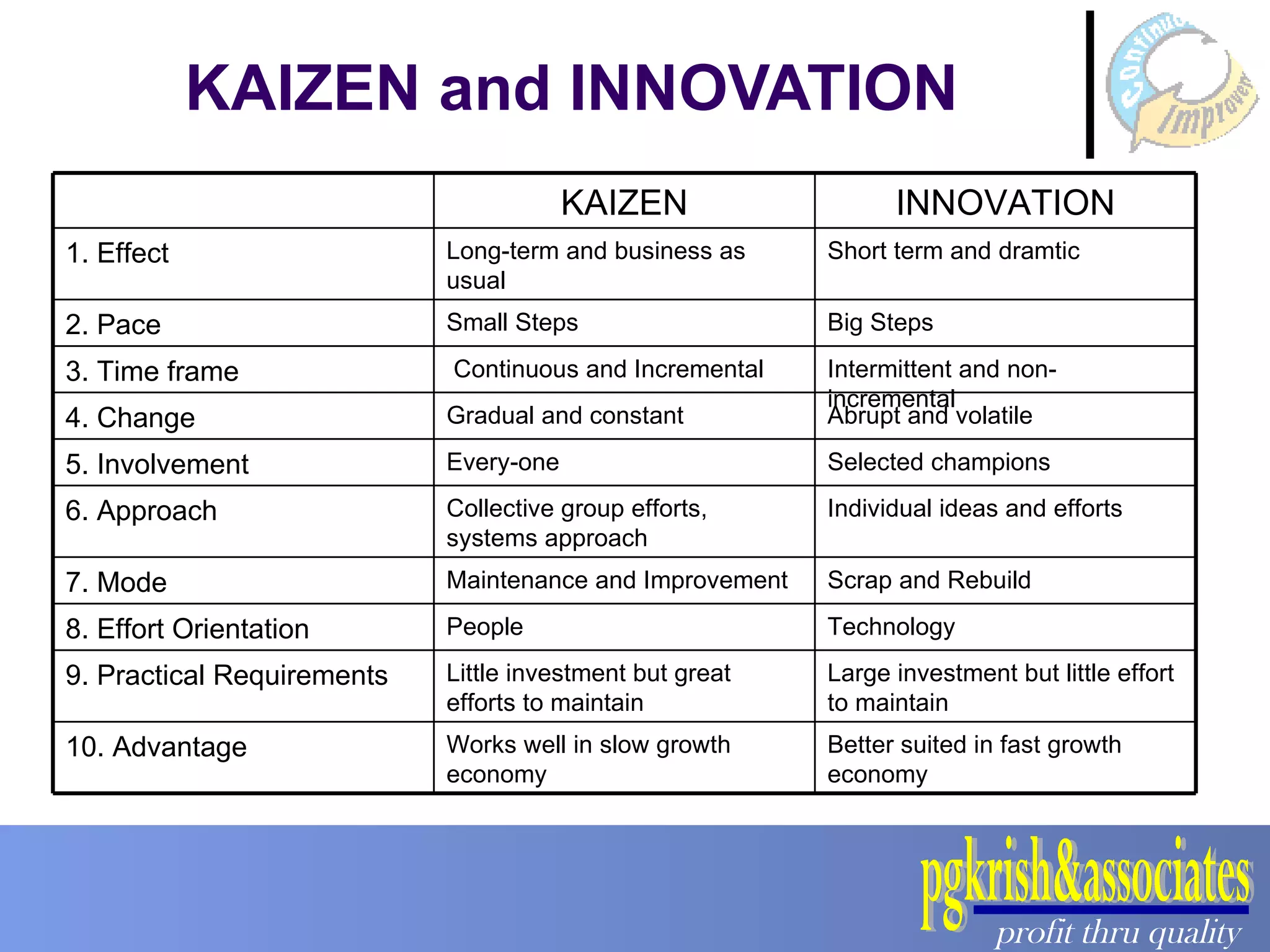

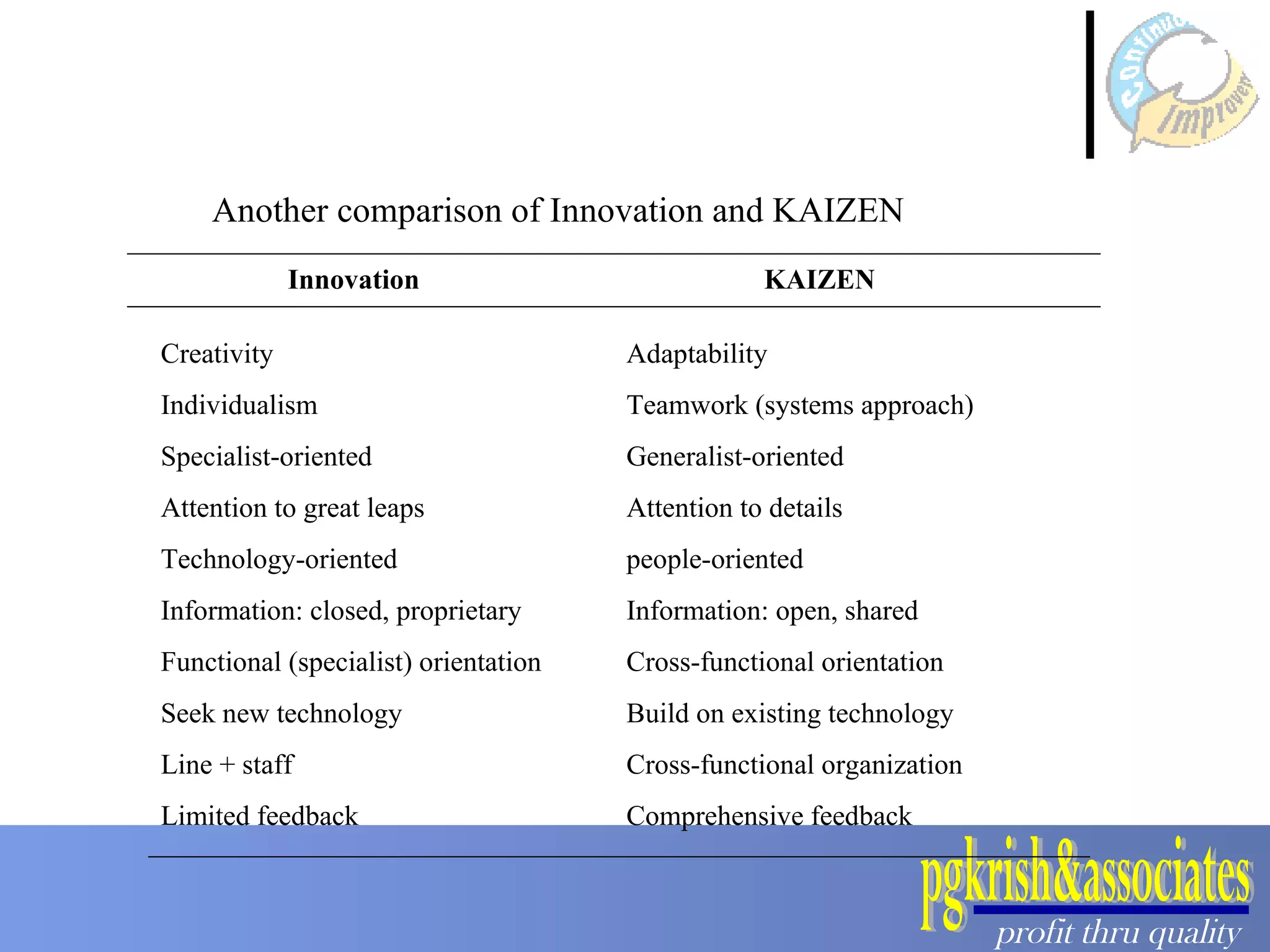

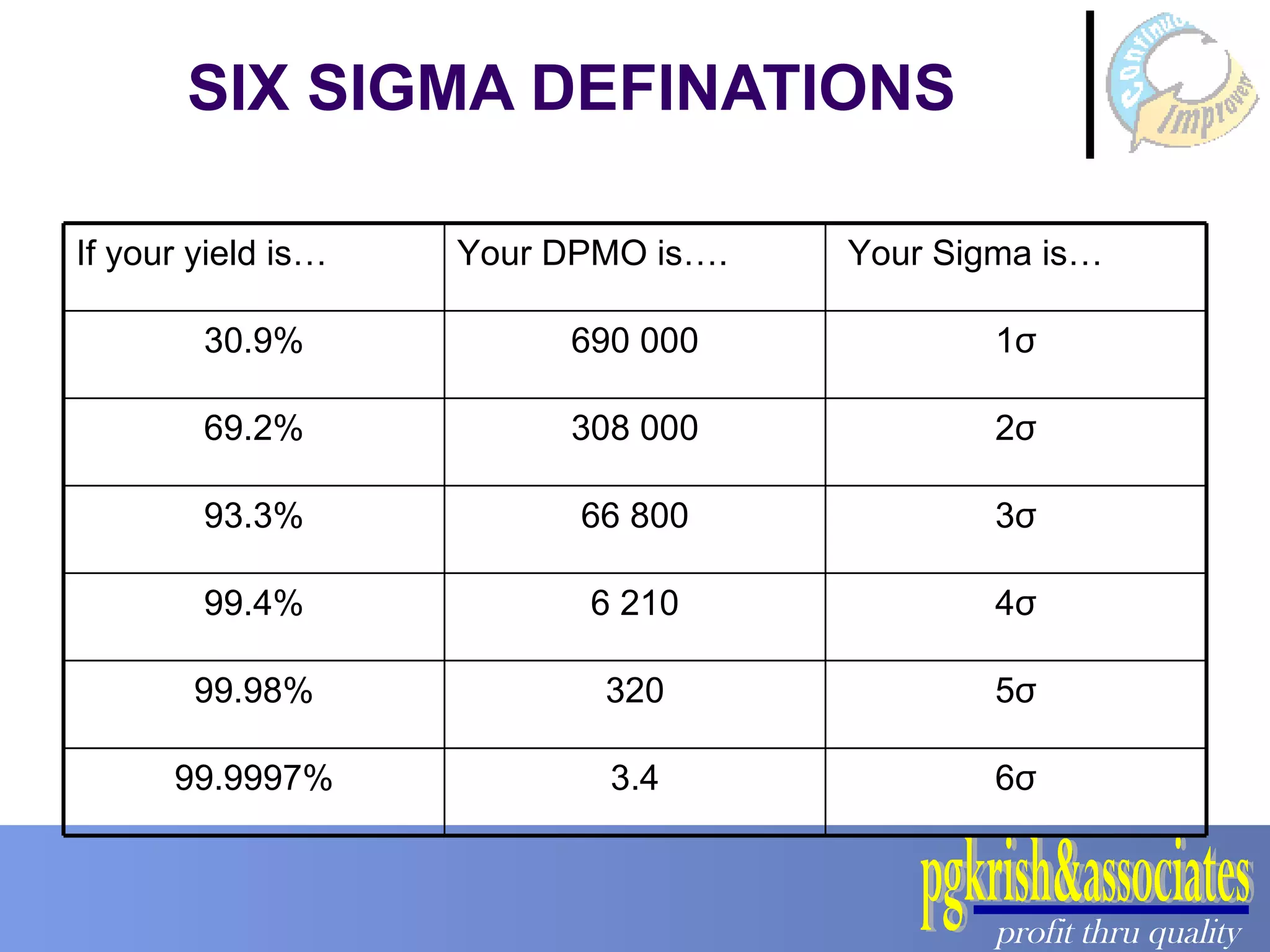

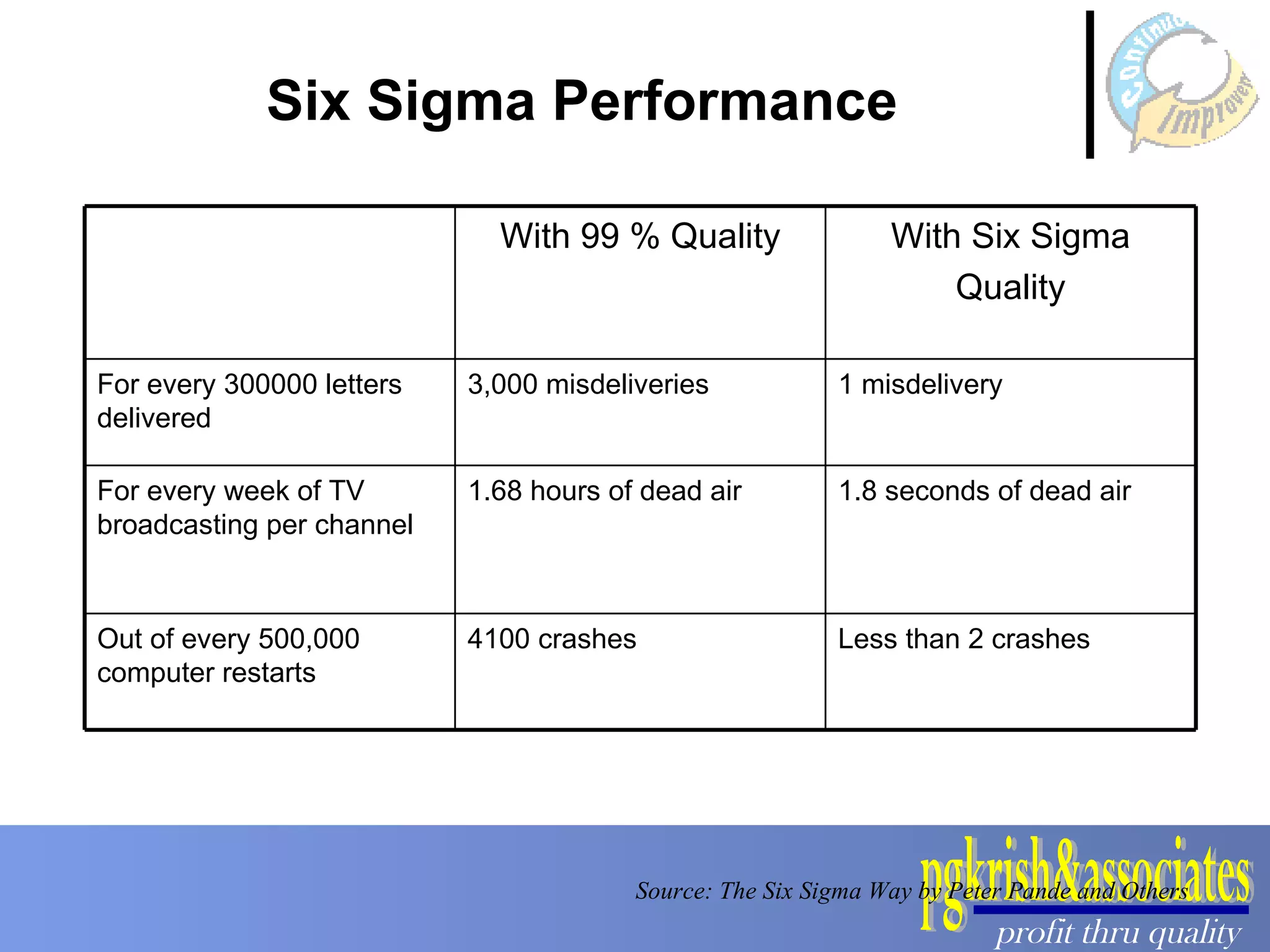

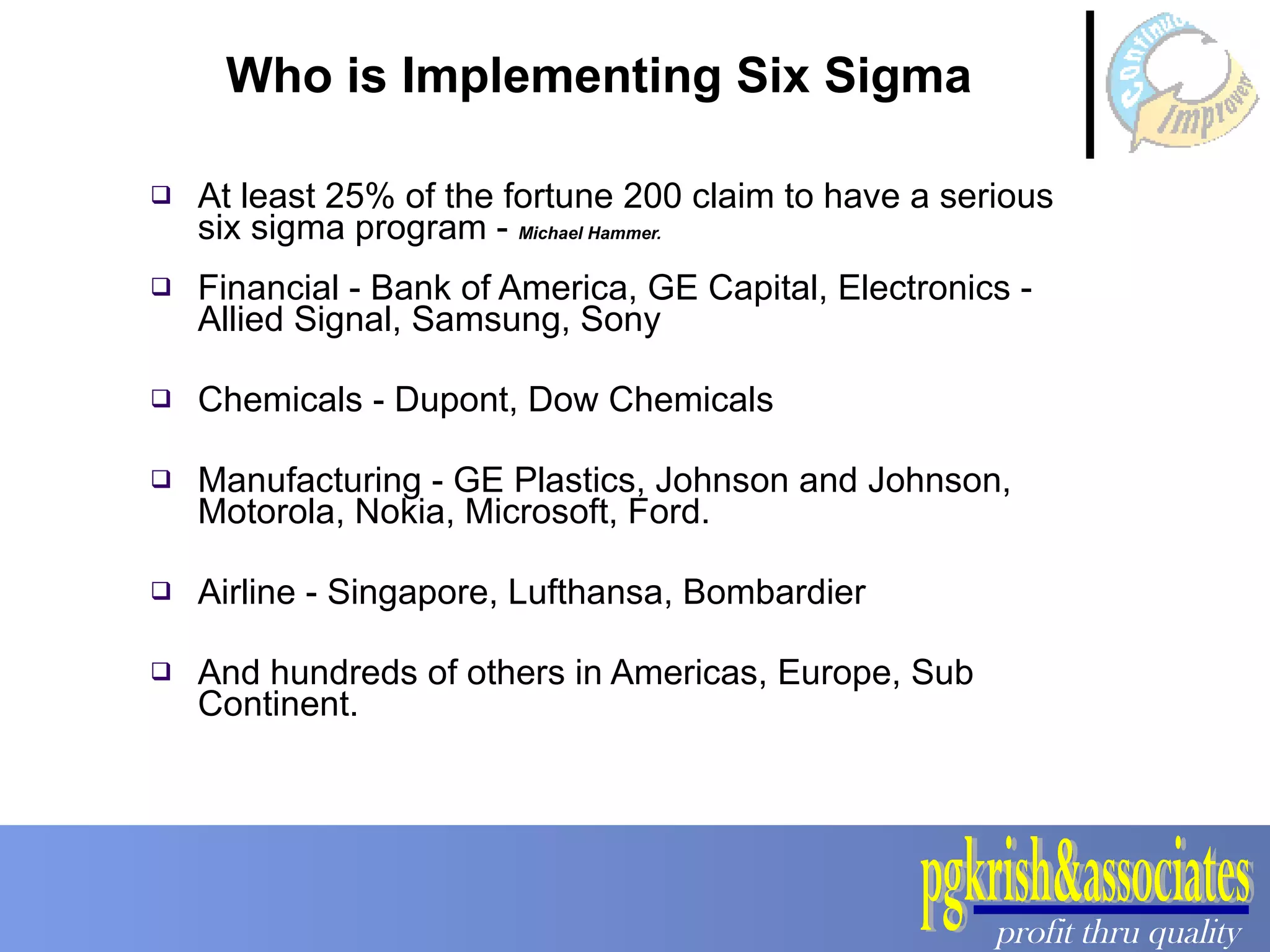

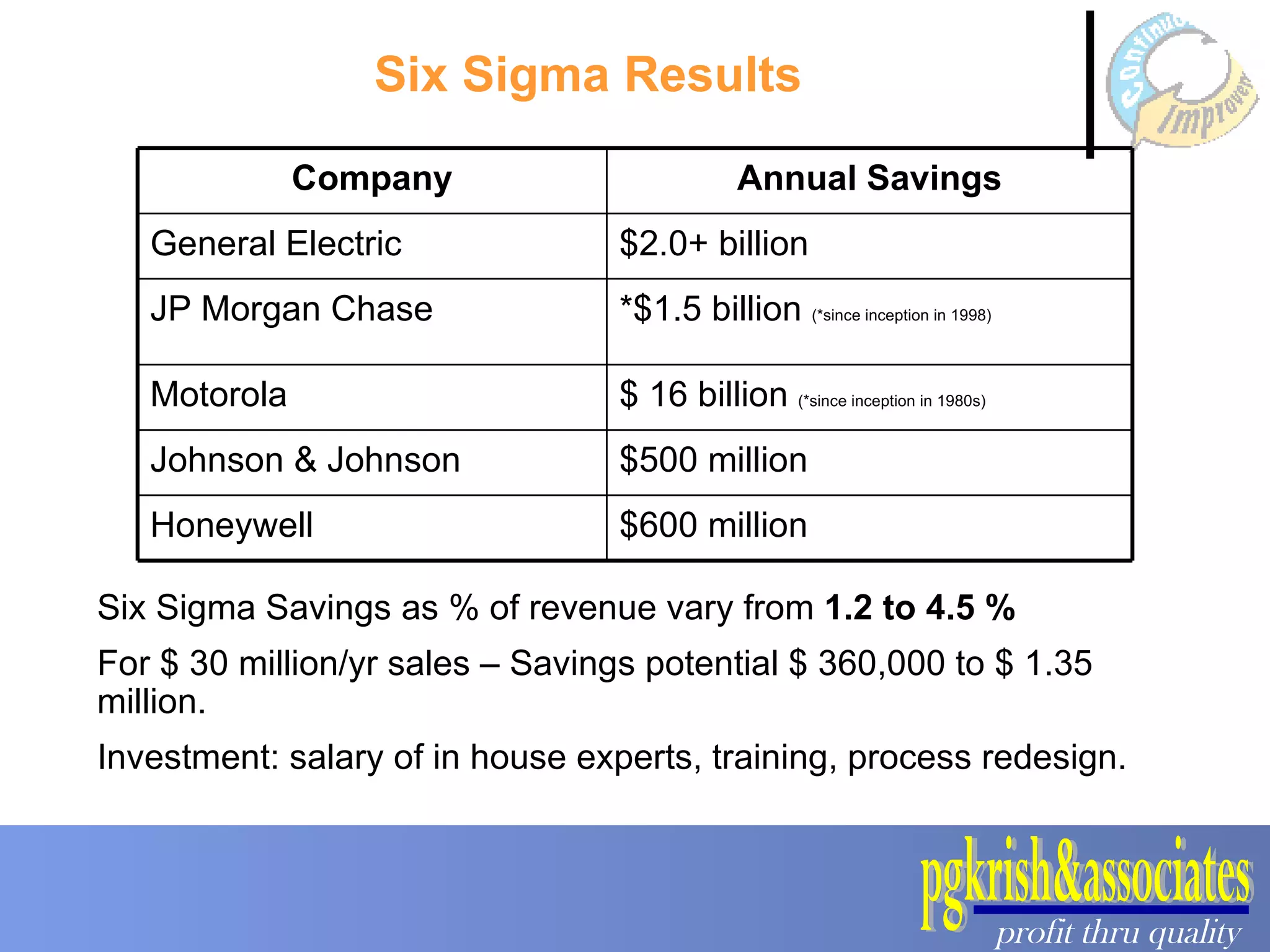

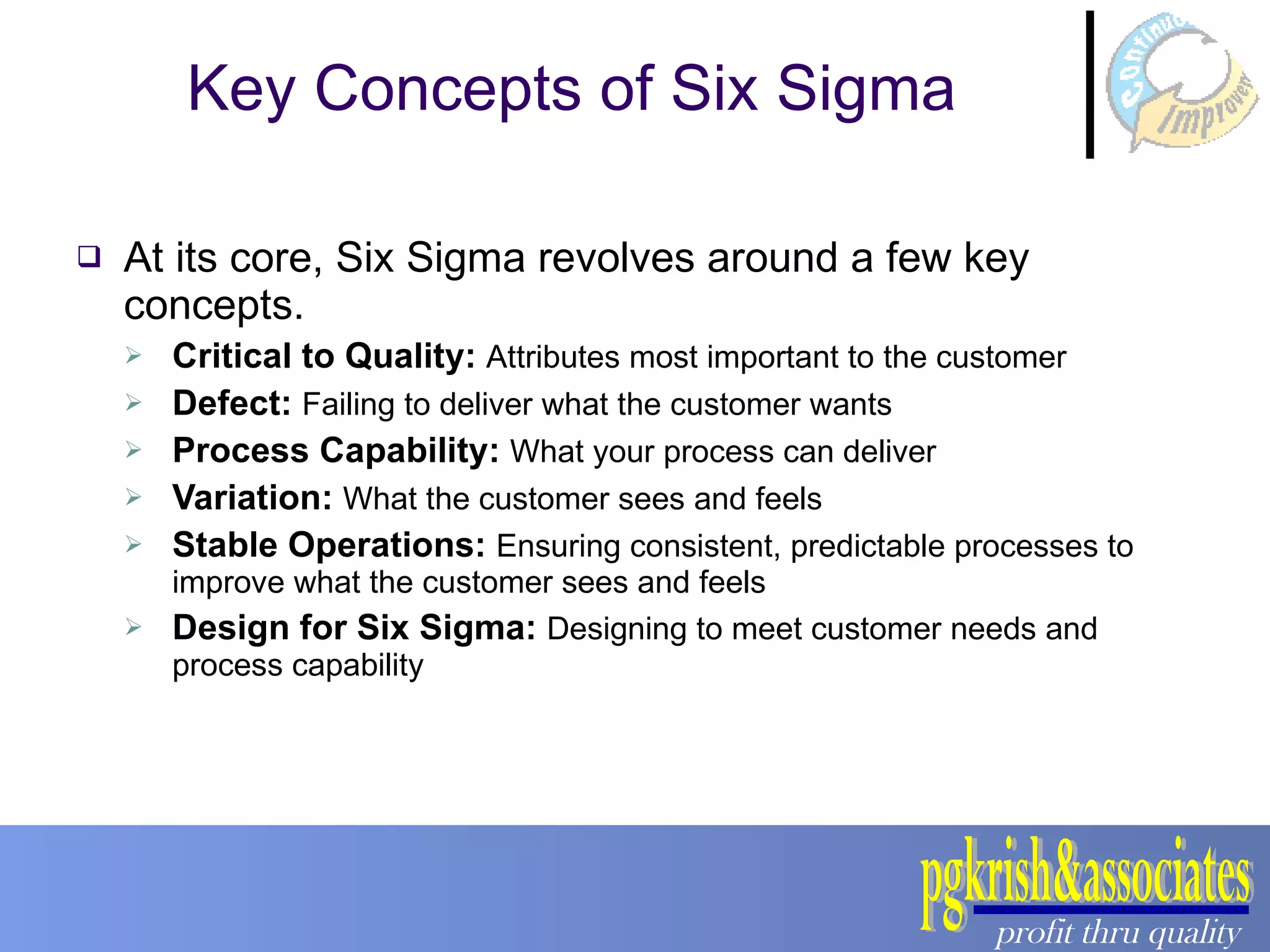

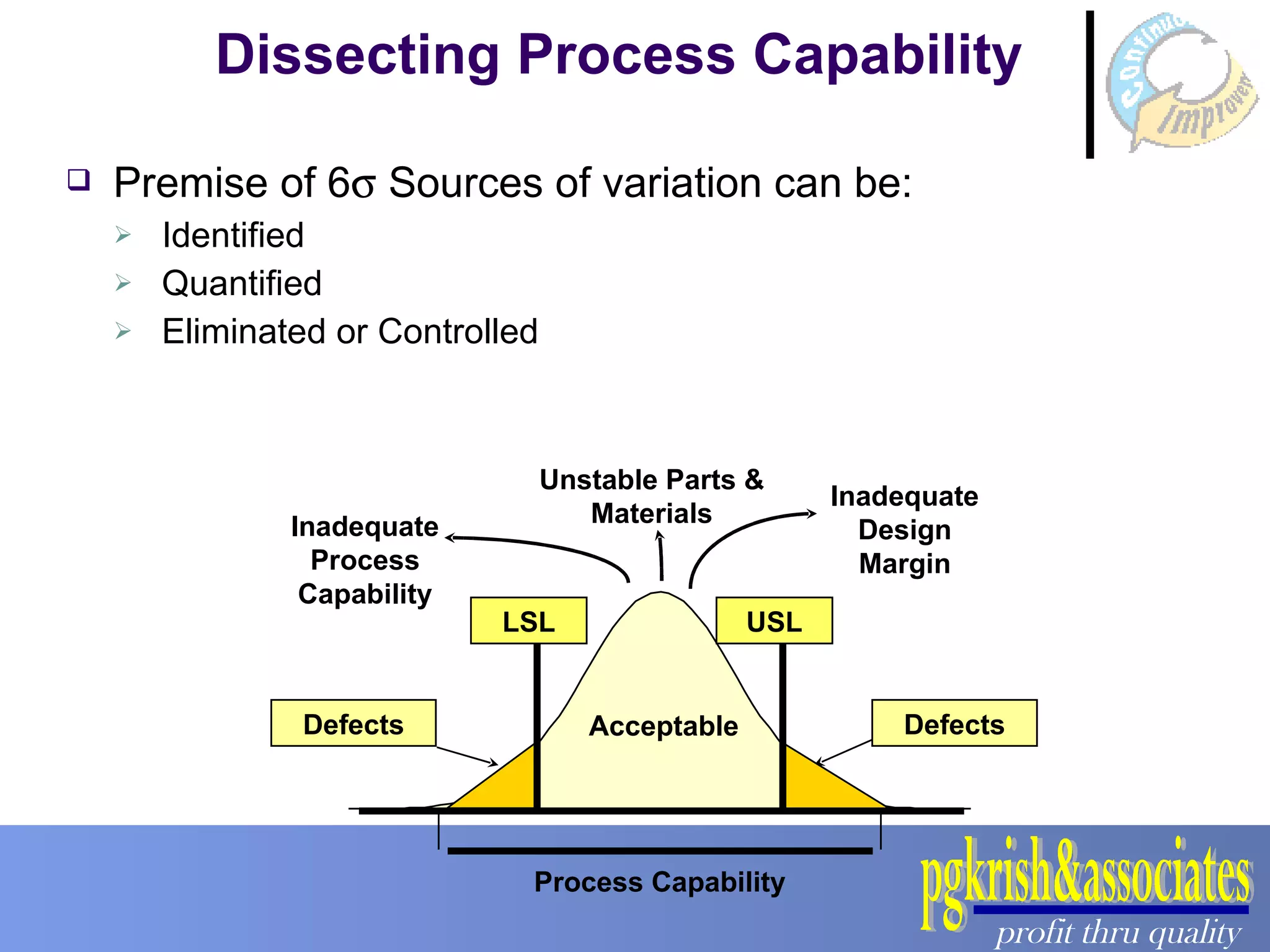

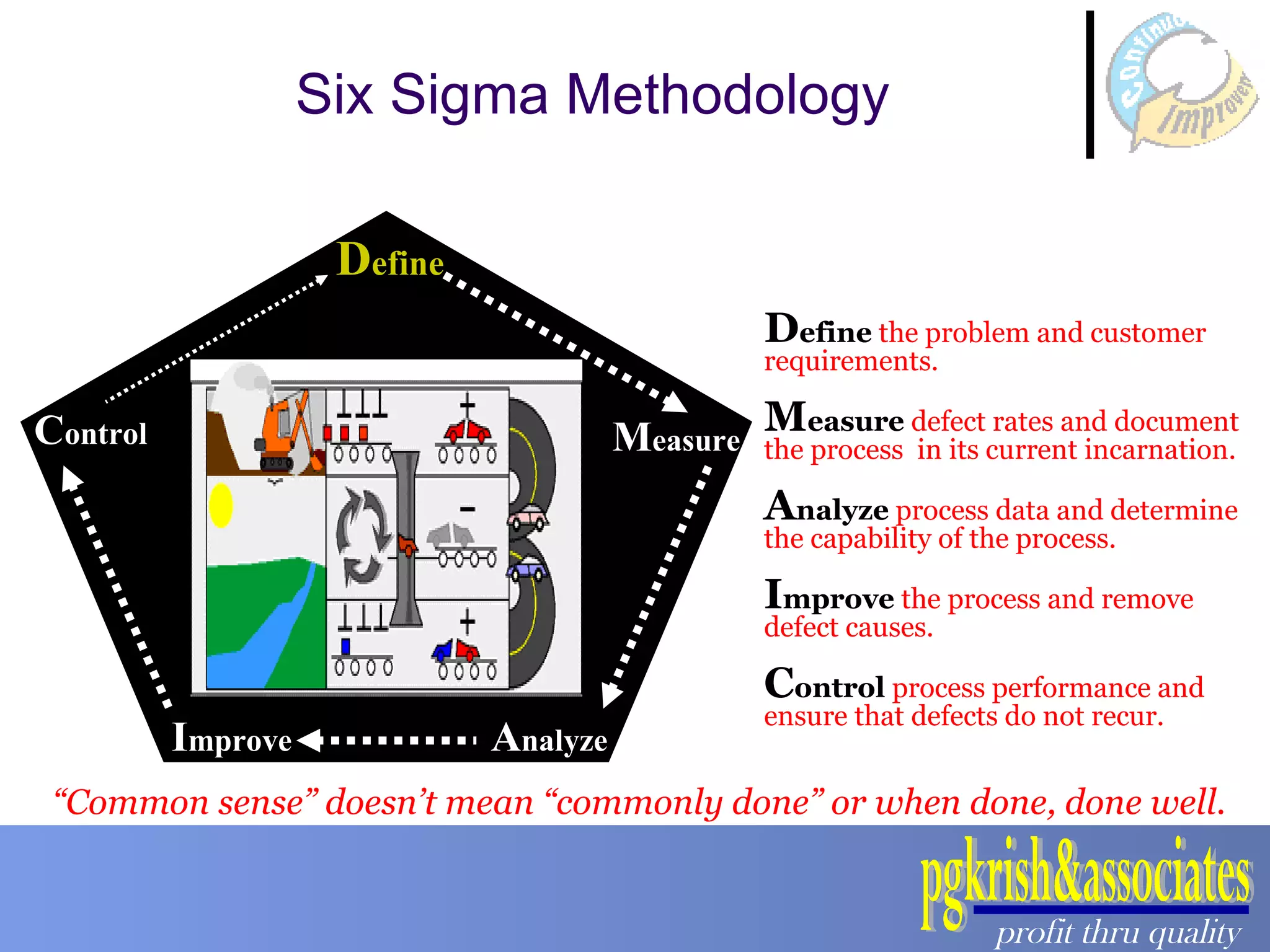

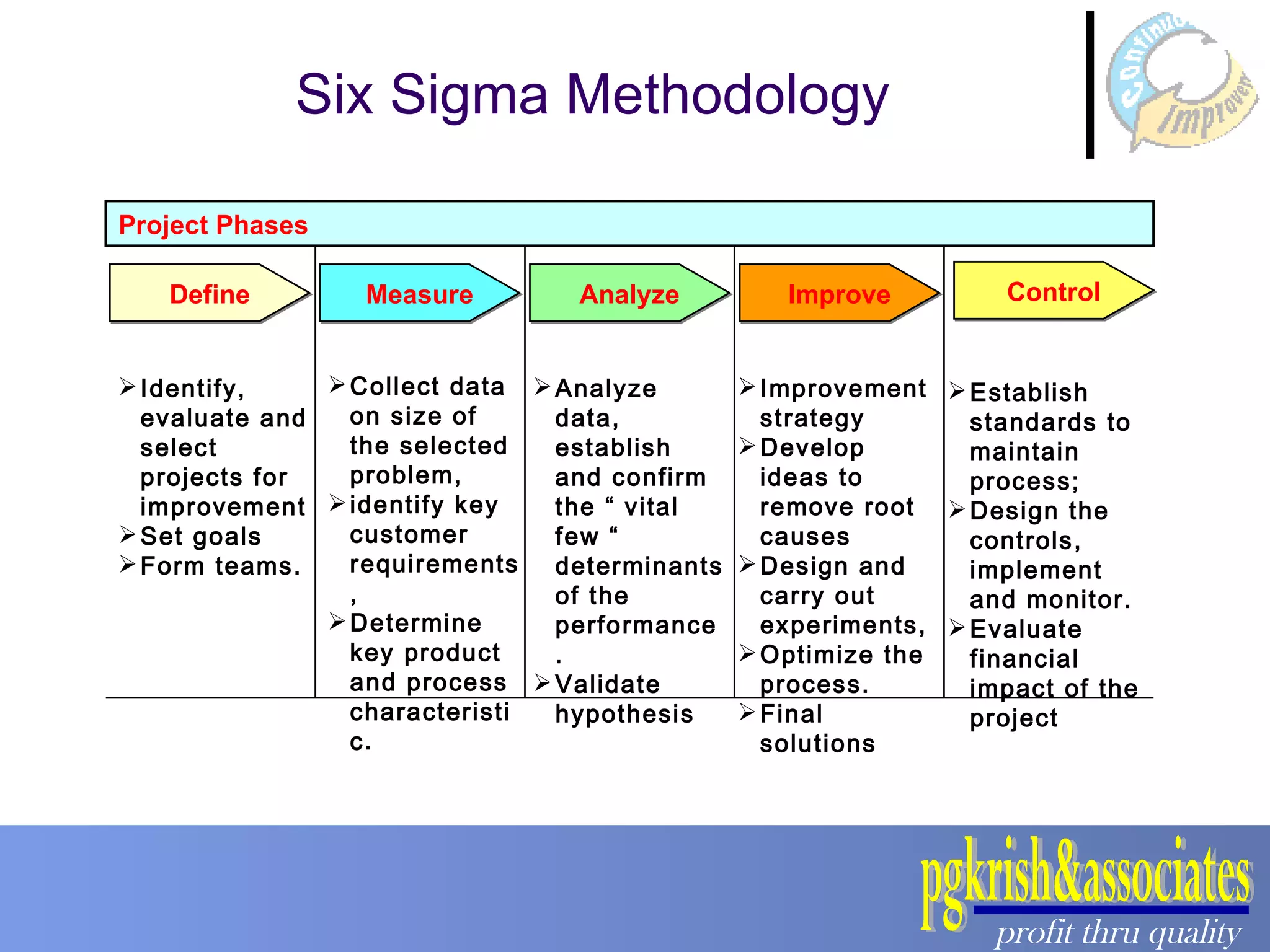

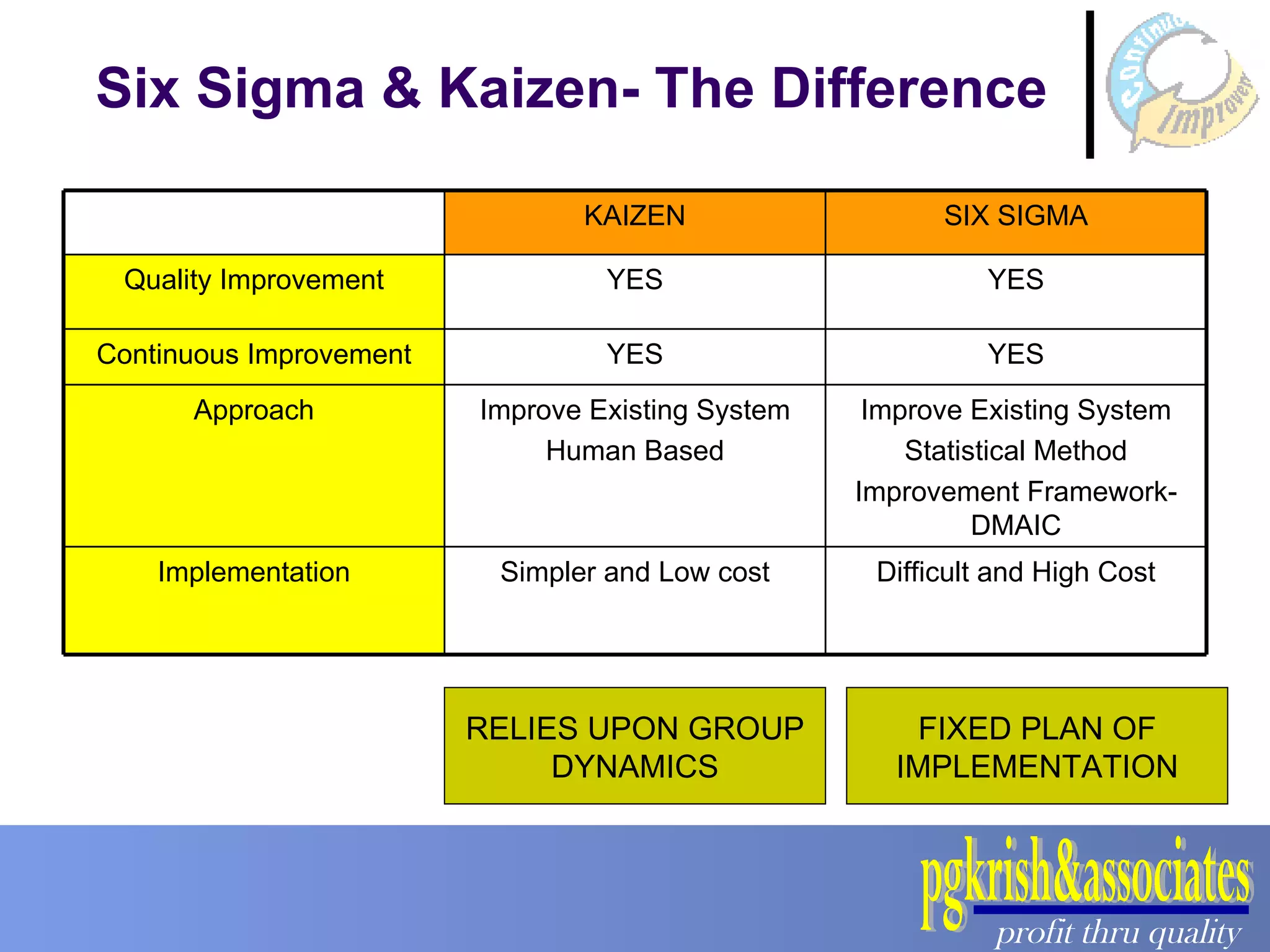

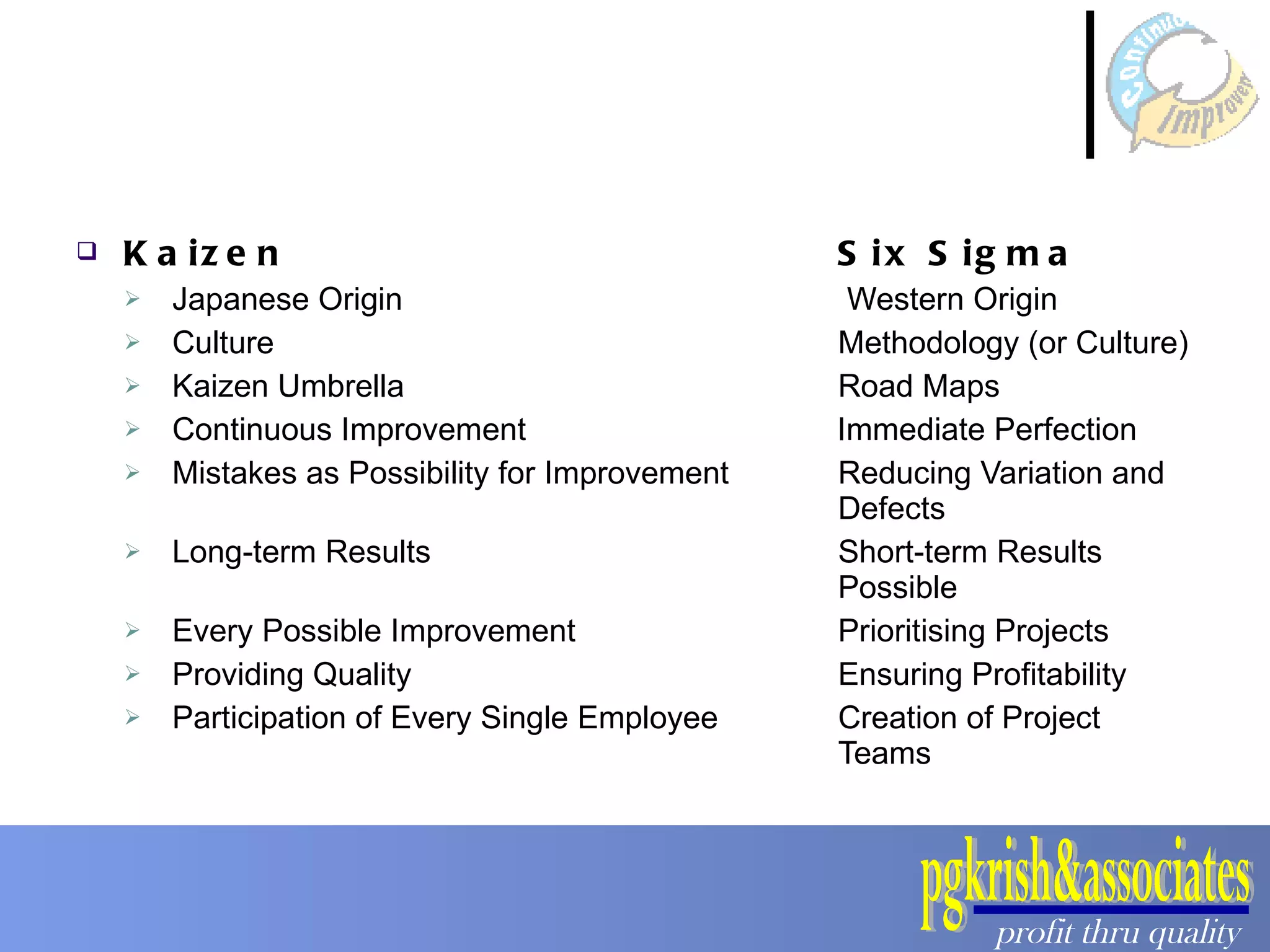

The document discusses various quality improvement concepts including Six Sigma, Kaizen, and their differences. Six Sigma uses a statistical approach to reduce defects through the DMAIC methodology. It aims for near perfect quality levels. Kaizen focuses on continuous incremental improvements involving all employees. While Six Sigma targets reducing variation, Kaizen prioritizes short-term gains through low-cost improvements and group activities like quality circles. Both concepts emphasize top management commitment and aim to enhance customer satisfaction and business performance over the long run.