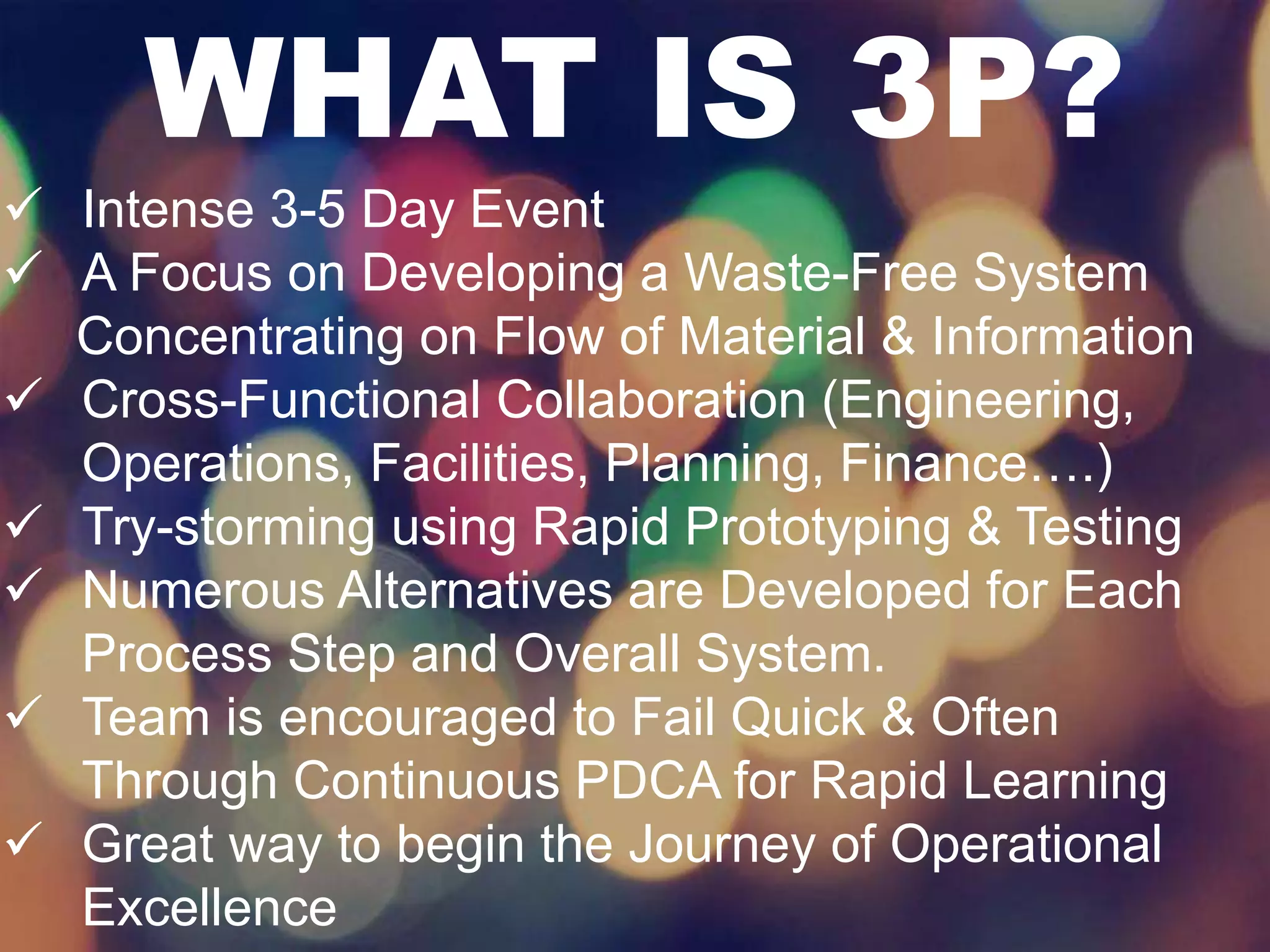

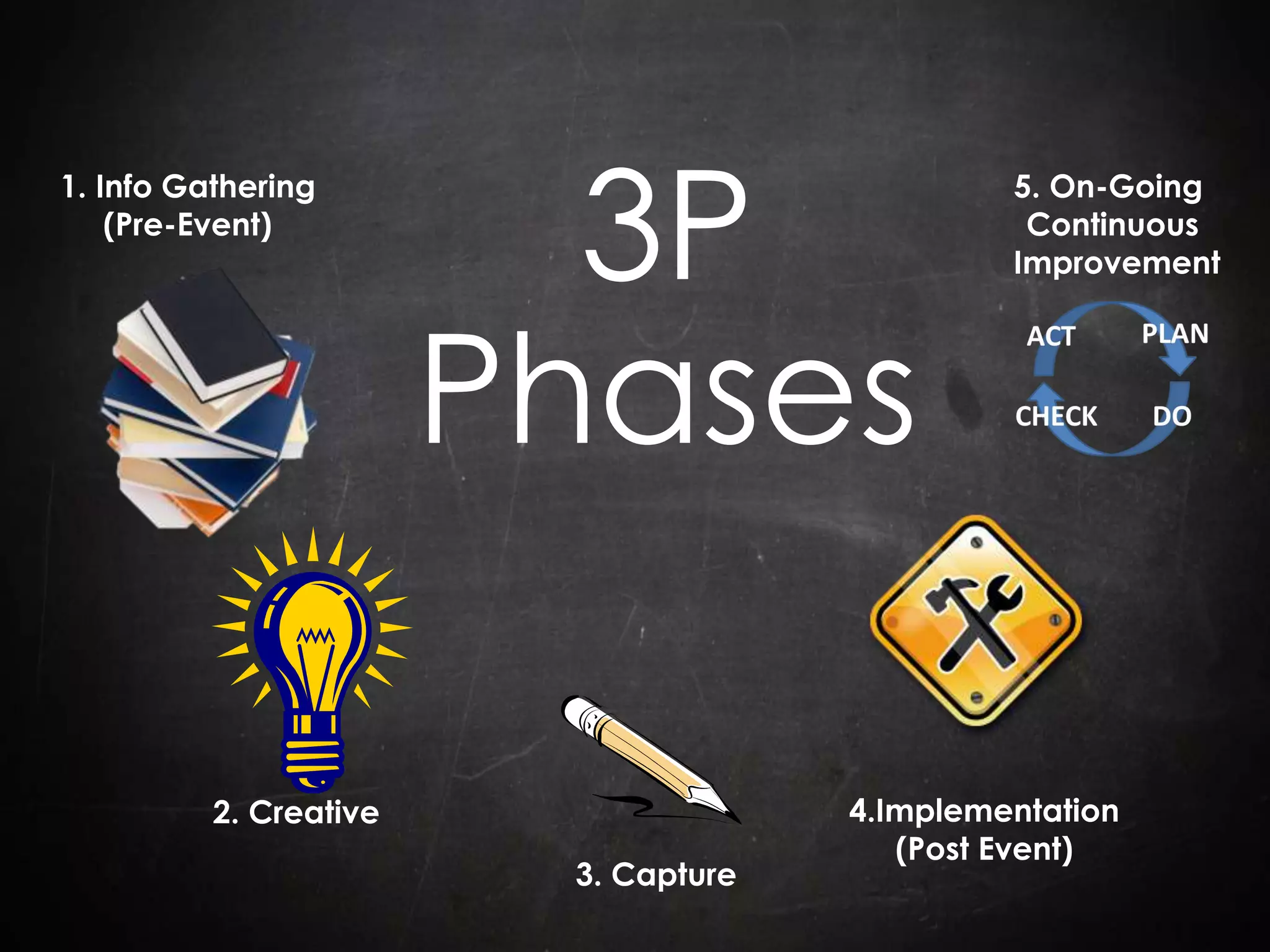

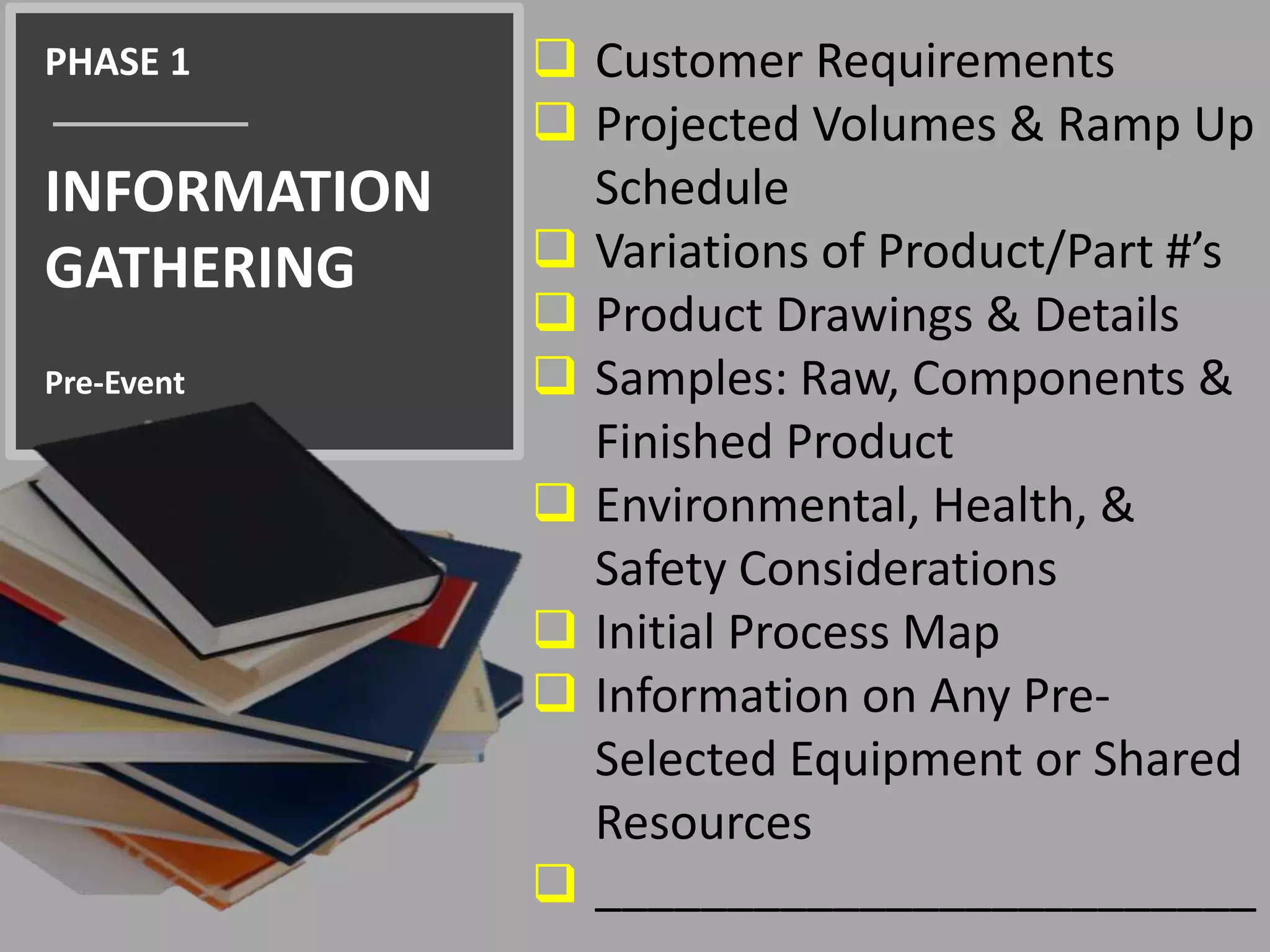

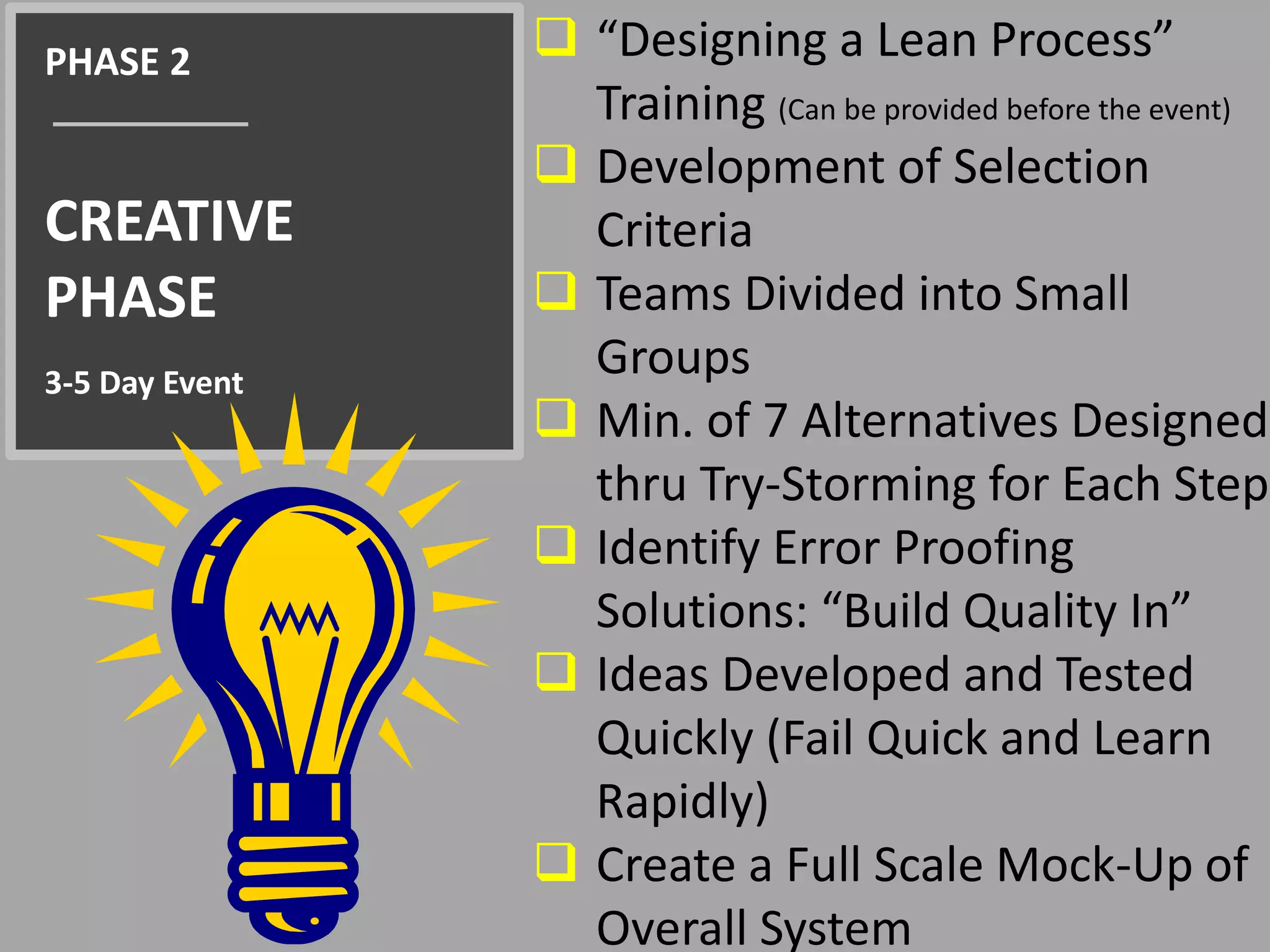

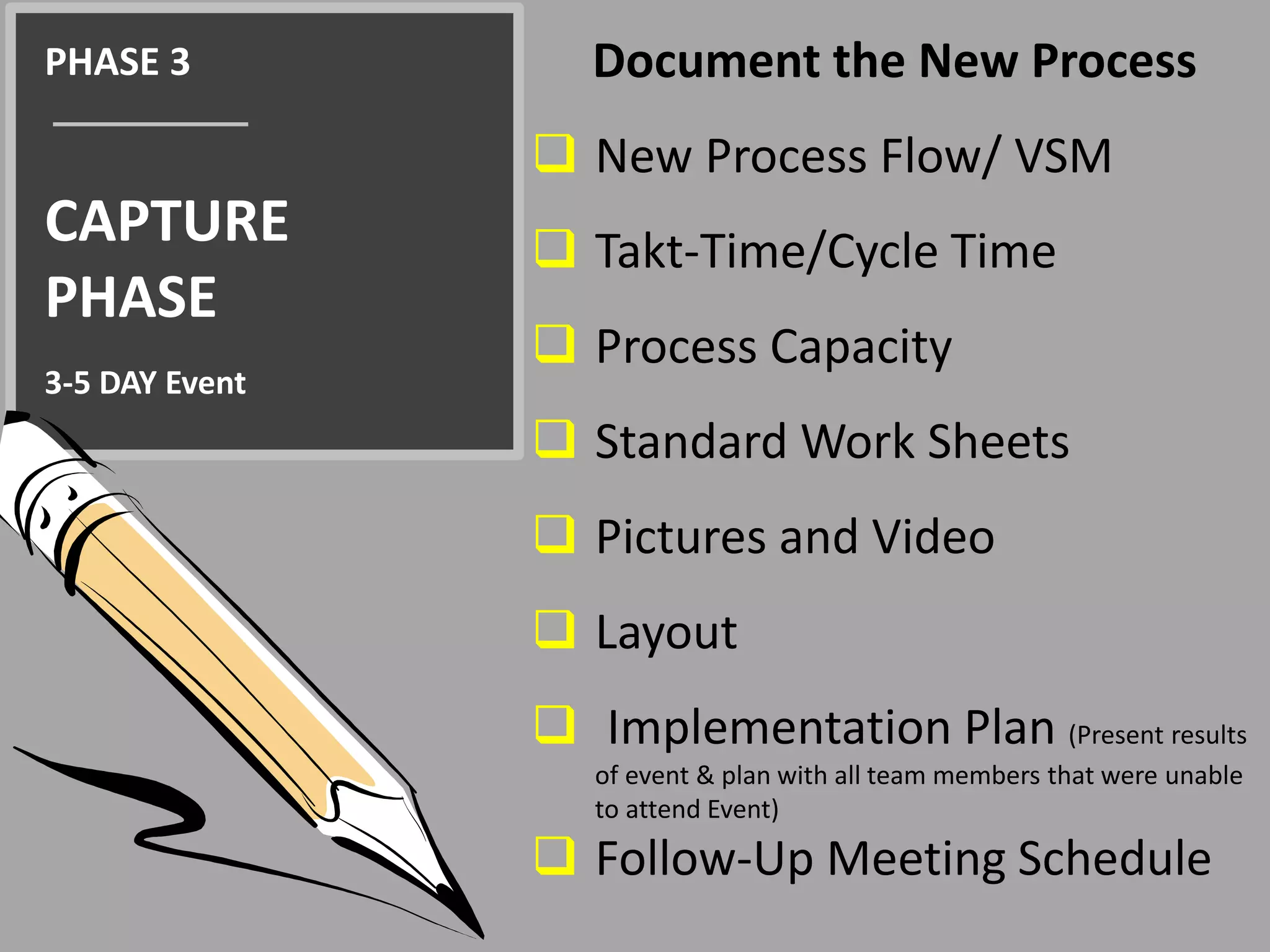

The document describes a 3P (Production Preparation Process) event, which is an intense 3-5 day workshop to design lean manufacturing processes. A cross-functional team collaborates in the 3P to develop waste-free systems focused on material and information flow. Through rapid prototyping and testing alternatives, the team aims to launch new products and processes quicker with reduced costs and built-in quality. The 3P follows phases of information gathering, creative development of alternatives, capturing the new process design, implementation, and ongoing continuous improvement.