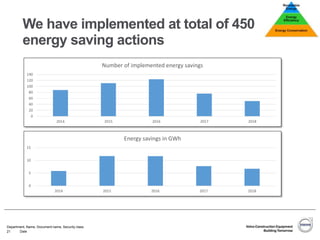

The document highlights the energy management initiatives led by Dr. Johan Wollin at Volvo, focusing on sustainable transport solutions and reducing energy consumption. Key achievements include a 48% reduction in idle electricity use, 50 GWh in total energy savings, and a 27% reduction in energy costs per unit produced. The approach emphasizes energy efficiency, renewable energy use, and cultural changes within the organization to drive continuous improvements.