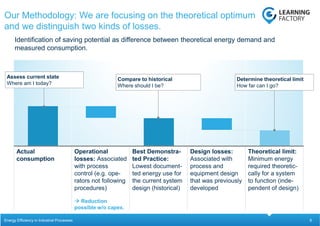

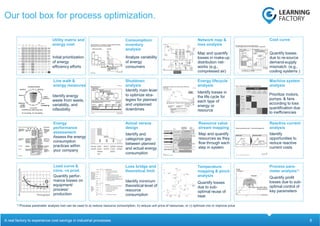

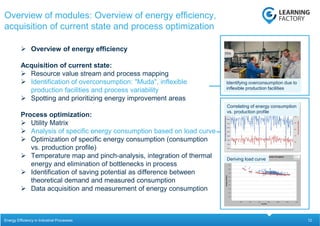

The document describes a training program on energy efficiency in industrial processes offered at the Learning Factory in Luxembourg. The 5-day training provides an overview of energy efficiency concepts and techniques, teaches methods to assess current utility usage and identify savings opportunities, and includes hands-on exercises to optimize various industrial systems and utilities using the Learning Factory's production facilities. Participants will learn how to map resource usage, measure energy consumption, analyze load curves, optimize processes, and quantify potential savings to lower operational costs.