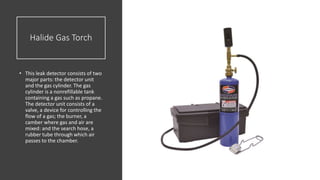

This document discusses different types of leak detectors that can be used to find refrigerant leaks, including electronic leak detectors, fluorescent dye, ultrasonic testers, and halide gas torches. Electronic leak detectors are very sensitive and can detect leaks as small as 0.5 oz per year. Fluorescent dye is injected into the refrigeration system and will indicate leaks under UV light. Ultrasonic testers can detect ultrasonic sounds from leaks that the human ear cannot hear. Halide gas torches use a propane cylinder and detector unit to identify leaks.