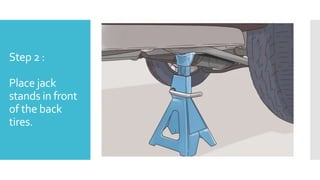

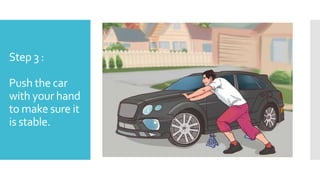

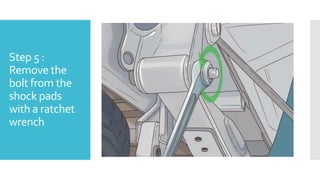

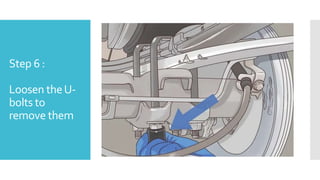

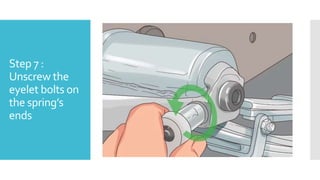

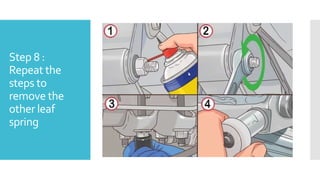

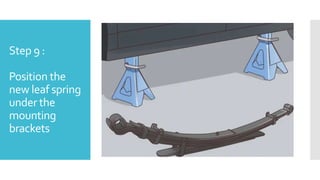

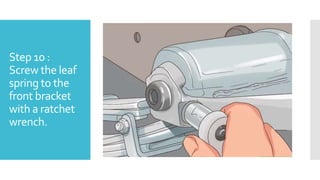

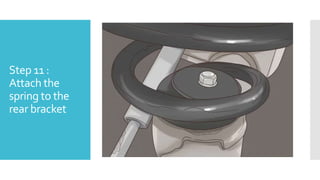

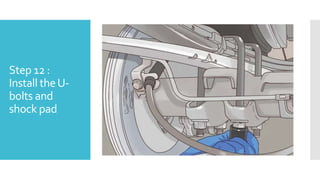

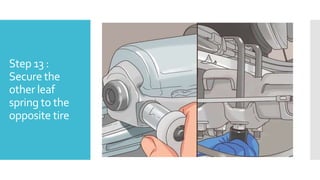

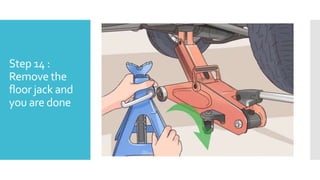

This document summarizes a leaf spring suspension system. It discusses that leaf springs are commonly used for heavy duty vehicle suspensions and are one of the oldest spring forms. The document outlines the typical dimensions and materials used for leaf springs. It then provides step-by-step instructions for replacing leaf springs and discusses advantages like simplicity and reduced weight, as well as disadvantages like reduced ride comfort over time. Finally, it notes that leaf springs are well-suited for commercial vehicles that need to support large vertical loads.