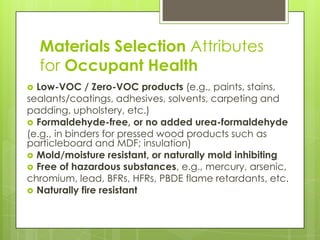

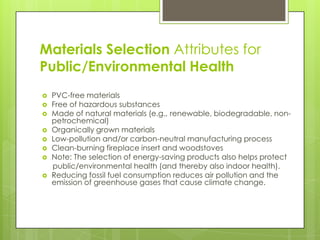

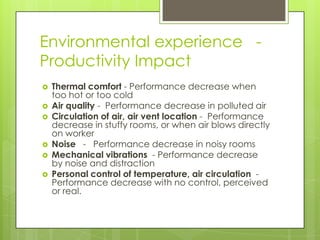

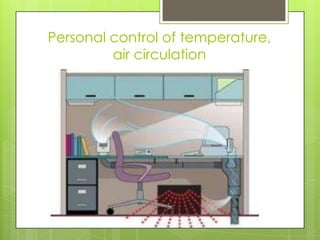

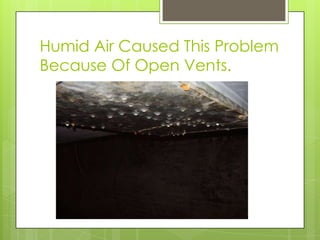

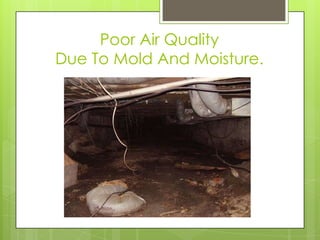

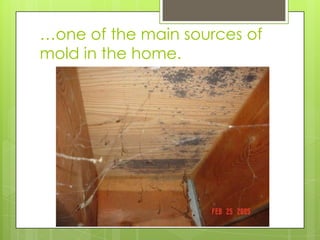

This document provides an overview of indoor environmental quality (IEQ) and strategies to improve indoor air quality (IAQ). It discusses why IAQ is important for health, lists common indoor pollutants like VOCs and strategies to reduce them through materials selection and ventilation. Specific strategies covered include using low-VOC products, formaldehyde-free materials, controlling moisture, and implementing third-party product certifications and construction practices to improve IEQ and occupant health and productivity.