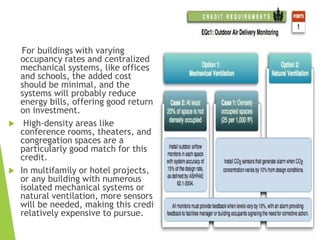

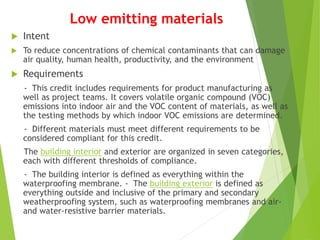

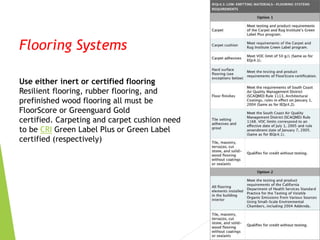

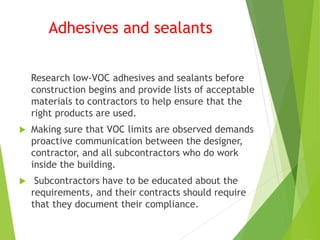

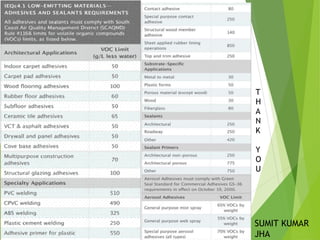

The document discusses indoor environmental quality (IEQ) and factors that affect it, including lighting, air quality, and damp conditions. IEQ encompasses indoor air quality, which focuses on airborne contaminants as well as comfort issues. Maintaining good IEQ is important for occupant health and well-being. The document outlines various strategies for ensuring good indoor air quality during construction and occupancy, such as implementing an indoor air quality management plan during construction, conducting flush-outs or air testing before occupancy, using low-emitting materials, and monitoring outdoor air delivery.