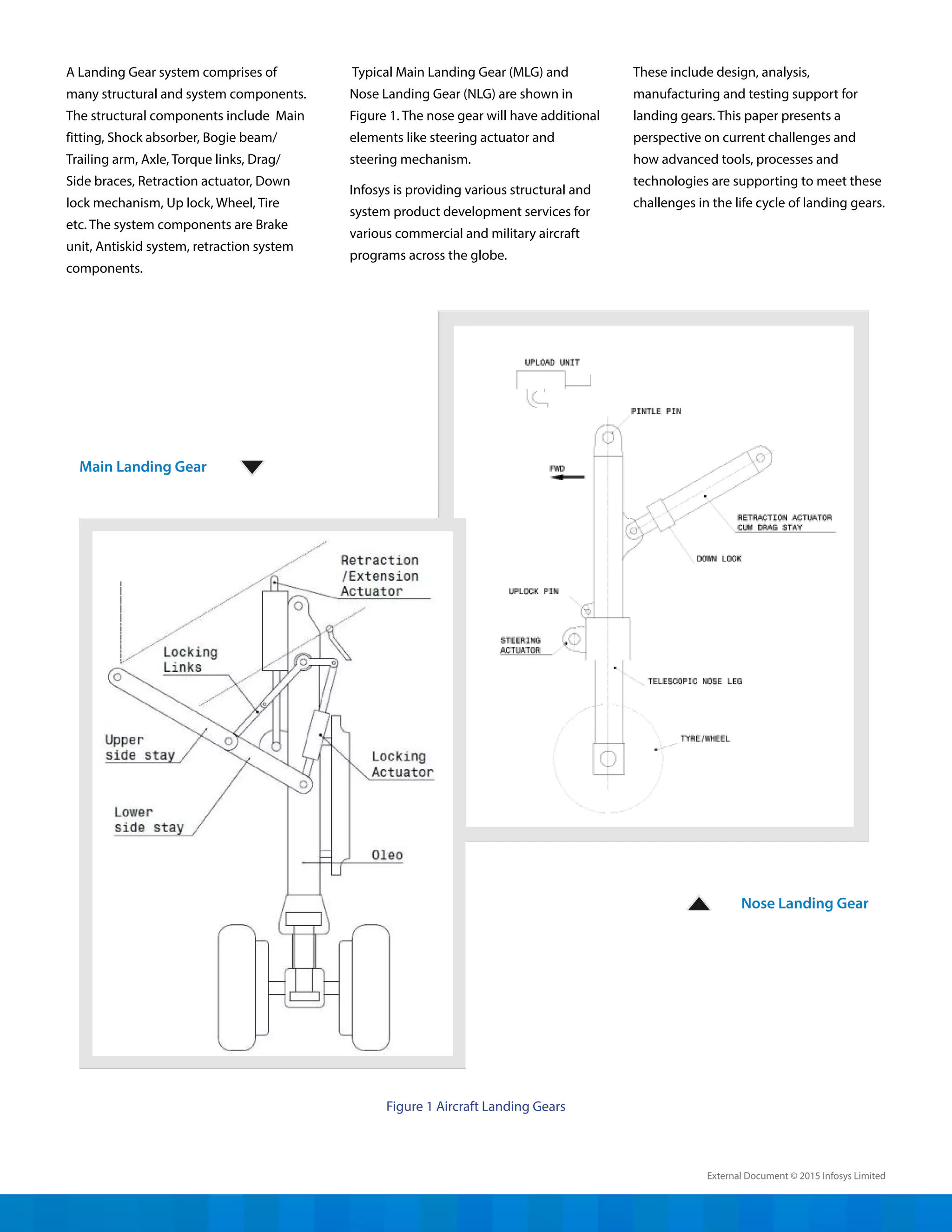

Landing gear is a critical subsystem of aircraft that must meet challenges of low weight and volume and high performance while withstanding high loads during landing. The document discusses the design and development process for landing gear, including concept design, preliminary design, detailed design, analysis, testing, and manufacturing. Advanced technologies help address challenges through tools for analysis, simulation, and digital prototyping and use of advanced materials.