This document provides an overview of LabVIEW and how it is used for FIRST robotics competitions:

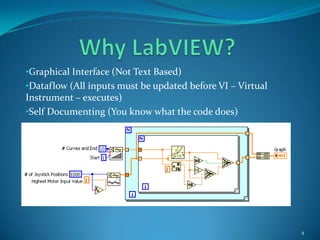

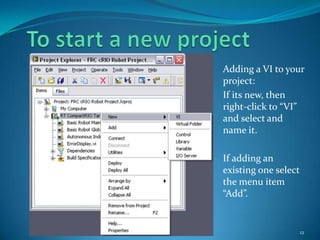

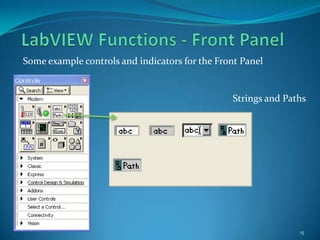

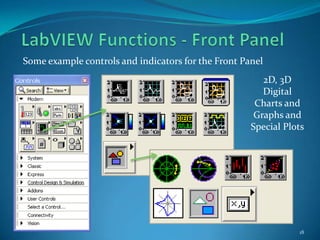

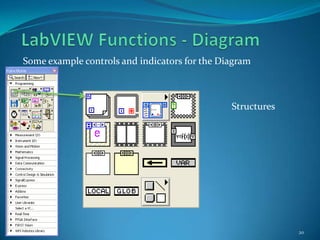

1. LabVIEW is a graphical programming language used with National Instruments hardware like the cRIO for robot control. Programs in LabVIEW are called VIs (virtual instruments).

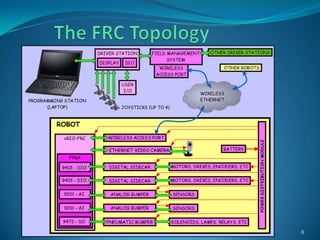

2. The cRIO is a programmable automation controller that serves as the robot's brain. It uses an FPGA and can interface with sensors, motors, and other hardware.

3. LabVIEW is well-suited for robotics as it is graphical, supports real-time control, and integrates tightly with NI hardware. Programs can be tested virtually before deployment to the robot.