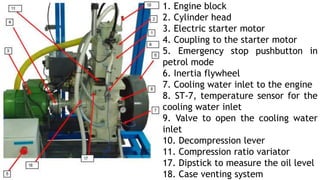

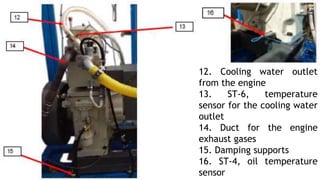

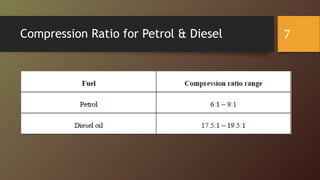

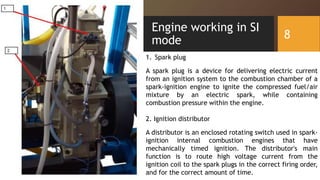

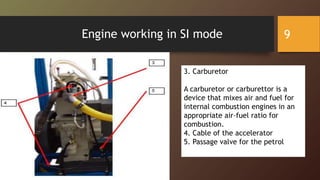

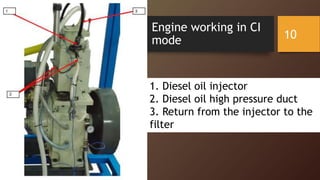

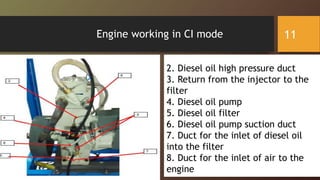

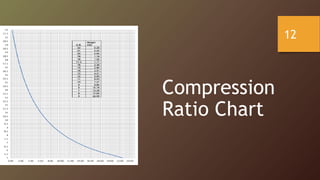

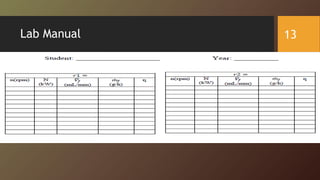

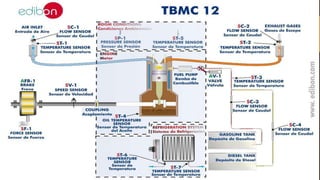

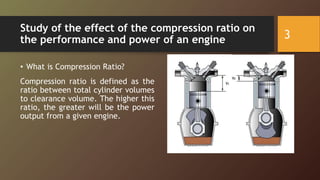

This lab involves studying the effect of compression ratio on engine performance and power for both spark ignition and compression ignition engines. Students will plot torque, power and performance curves at different speeds for varying compression ratios. The dual engine test bench allows students to examine both gasoline and diesel engines. Key components like the spark plug, ignition distributor and carburetor are used in spark ignition mode, while the diesel injector, high pressure fuel lines and pump are used in compression ignition mode. Charts of compression ratio and the engine components are provided.

![Water-Cooled Dual Engine [TM12-01]

Engine Specifications

Type of engine Spark ignition/

compression ignition

Maximum power 5.8 kW/1800 rpm CR 18:1

5.7 kW/1800 rpm CR8:1

Fuel Petrol/Diesel Maximum torque 30 N.m

No. of cylinders 1 Type of air intake Naturally aspired

No. of strokes 4 Type of cooling Water

Cylinder bore 87.5 mm Starter Electric

Cylinder stroke 110 mm Compression ratio Variable

2](https://image.slidesharecdn.com/lab10-231224132619-a4d30289/85/Lab-10-pptx-power-plant-engineering-ic-engine-2-320.jpg)

![4

General Description of Single Cylinder

Water Cooled Dual Engine [TM12-01]](https://image.slidesharecdn.com/lab10-231224132619-a4d30289/85/Lab-10-pptx-power-plant-engineering-ic-engine-4-320.jpg)