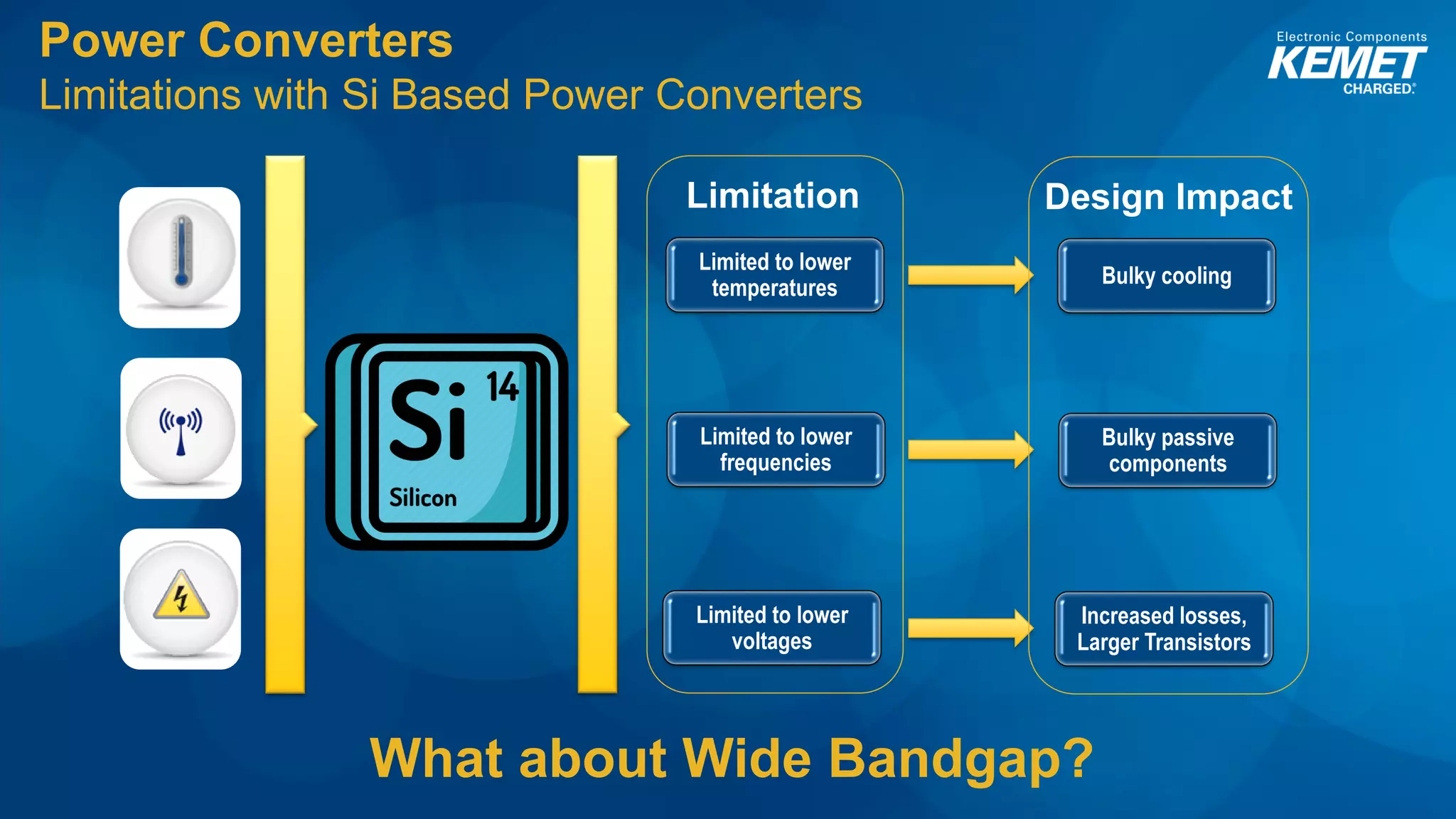

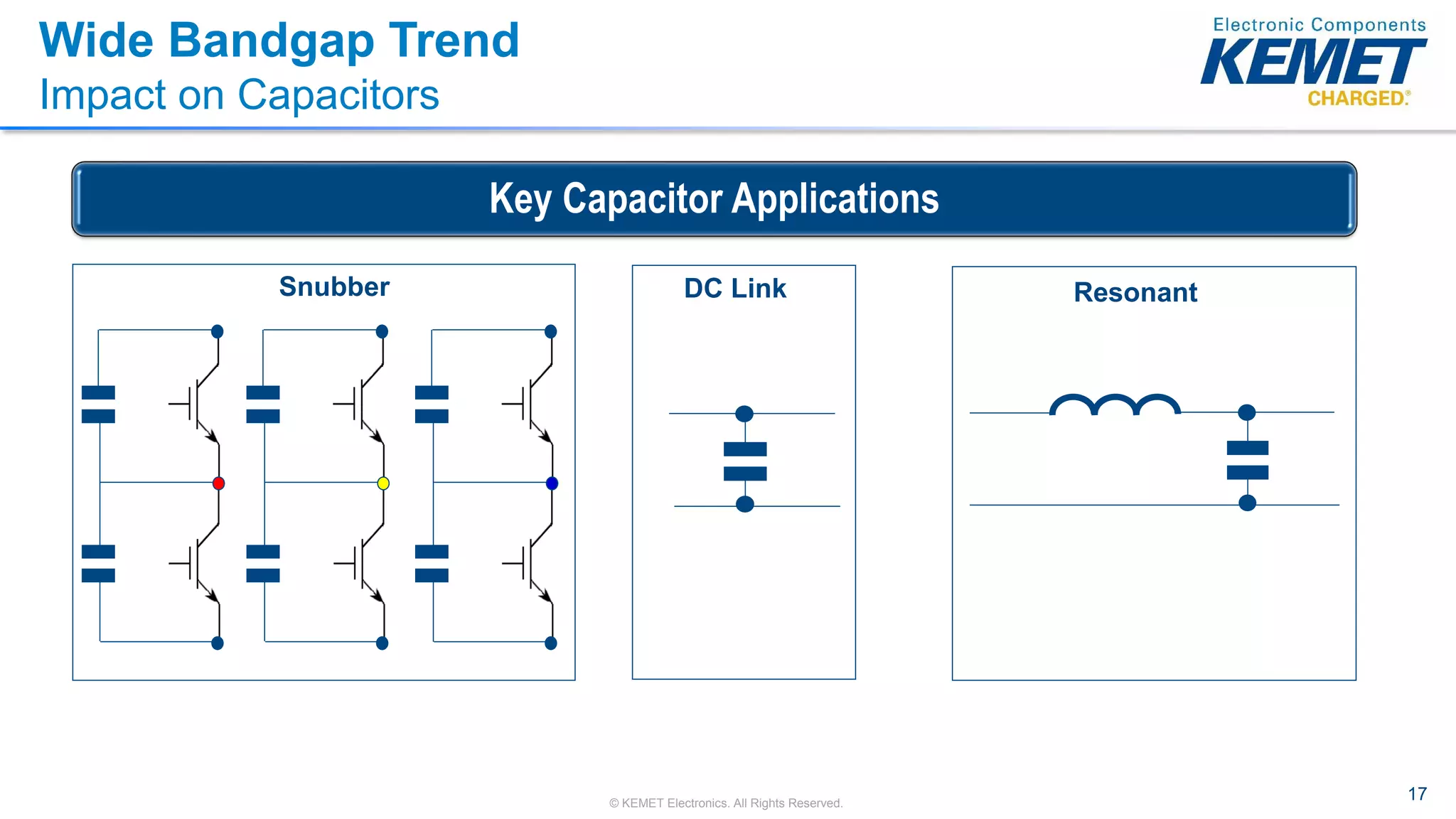

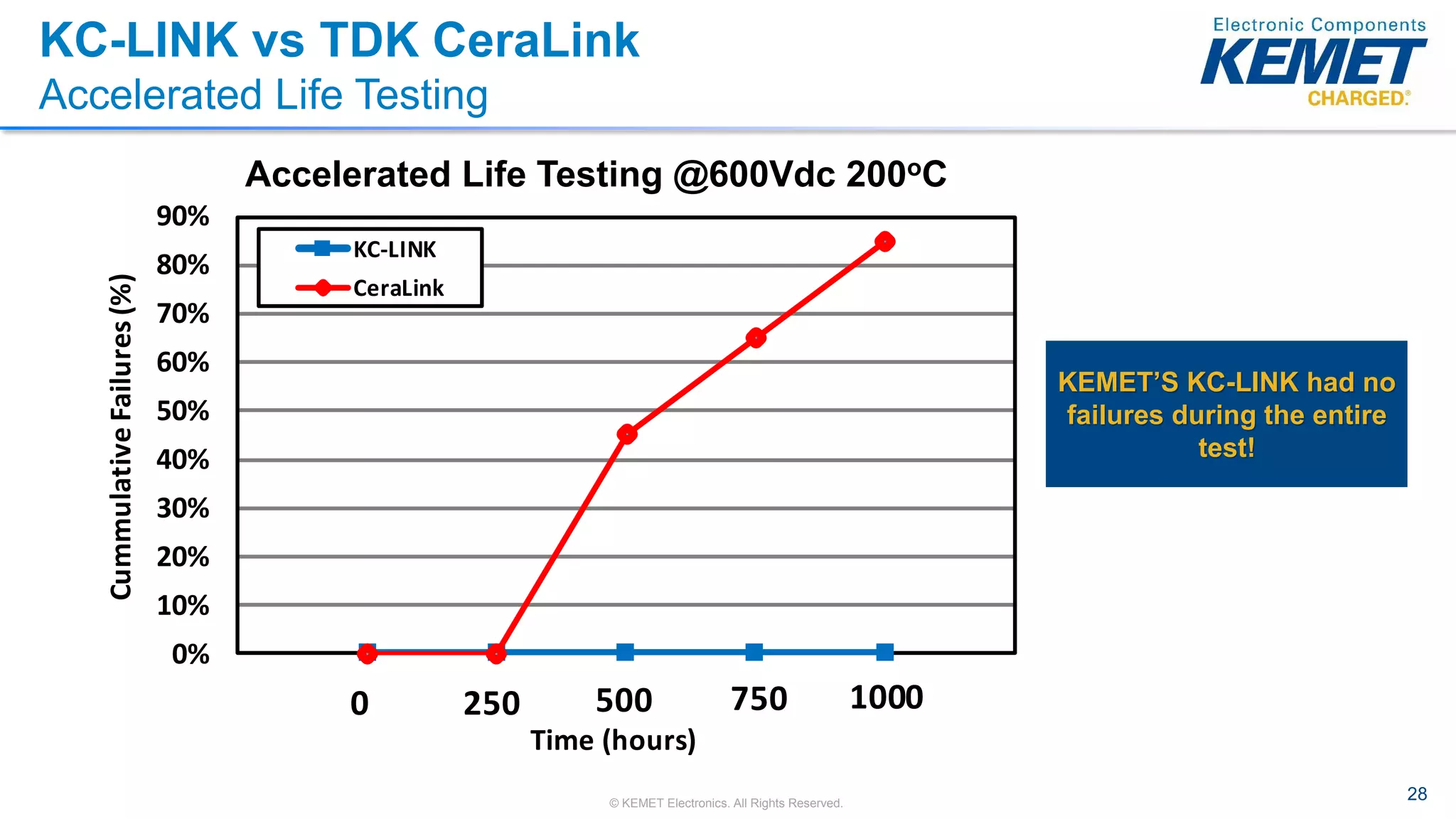

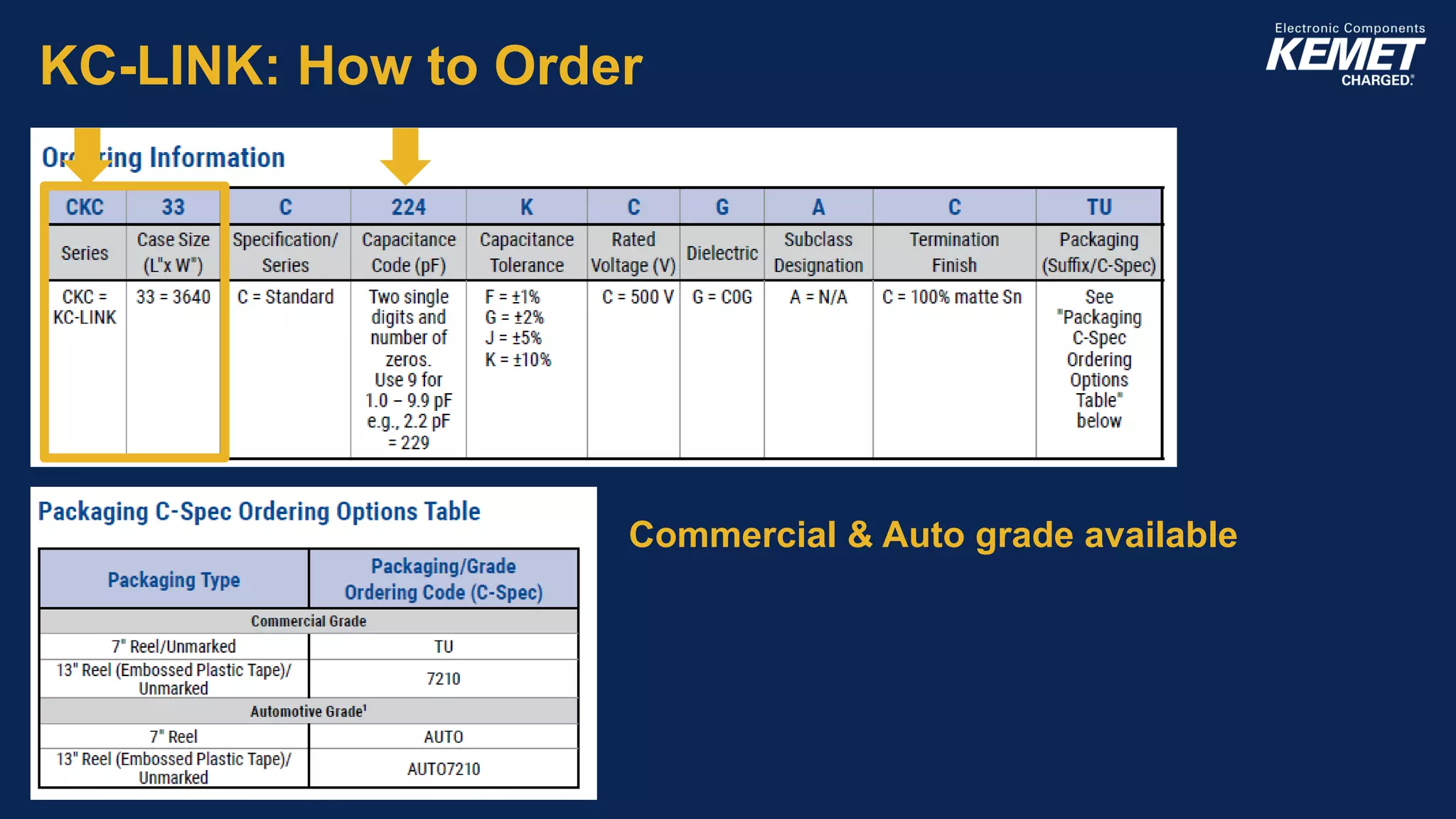

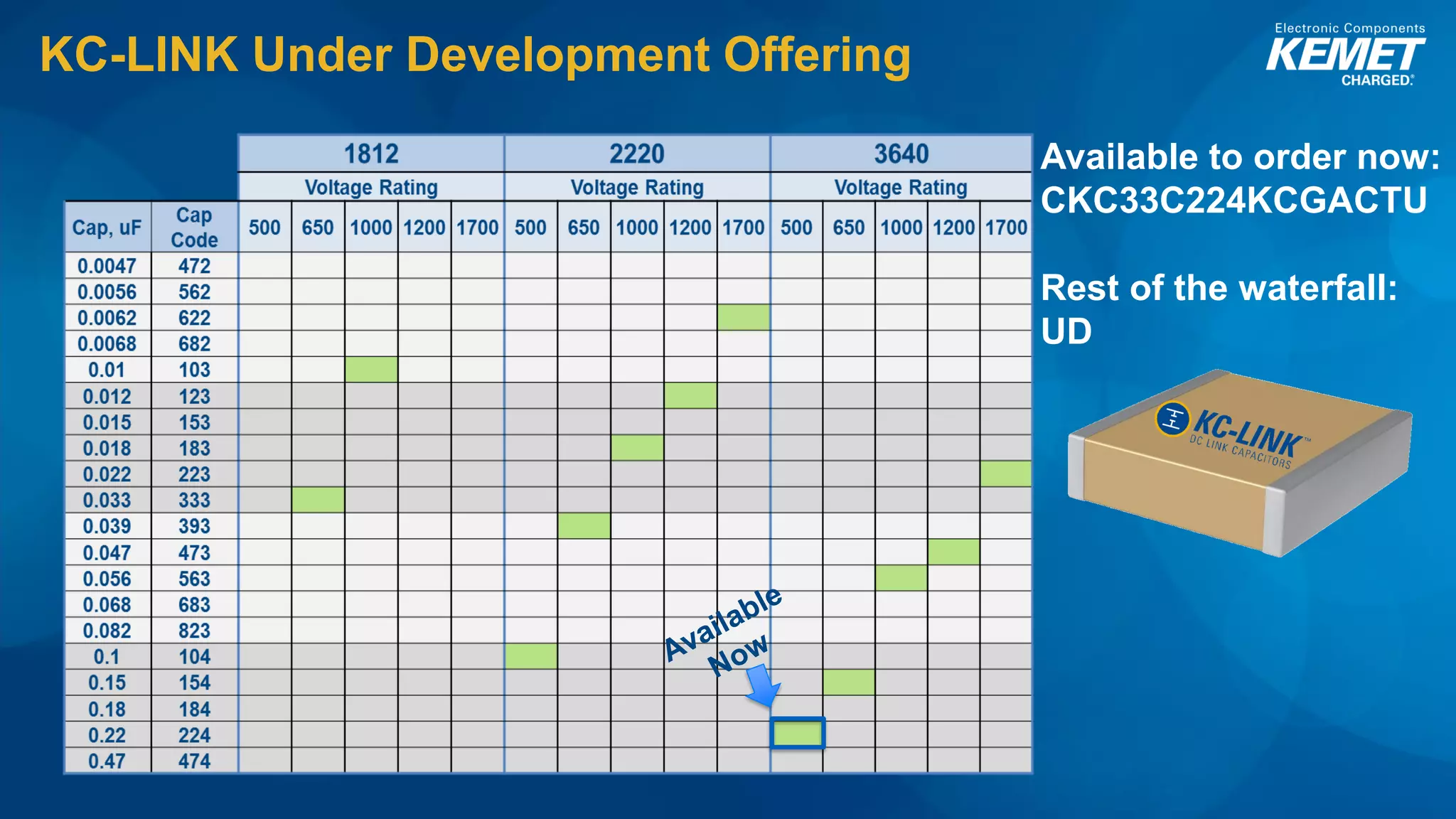

The webinar discusses the role of ceramic kc-link capacitors in power converters, emphasizing their importance in improving efficiency with wide bandgap (wbg) semiconductor technology. Key advantages of wbg include higher voltages, frequencies, and temperatures, leading to enhanced performance in electric vehicles and solar energy systems. The presentation highlights kc-link's low equivalent series resistance (esr) and inductance (esl) along with its high ripple current capacity, making it suitable for applications like snubber and dc-link systems.