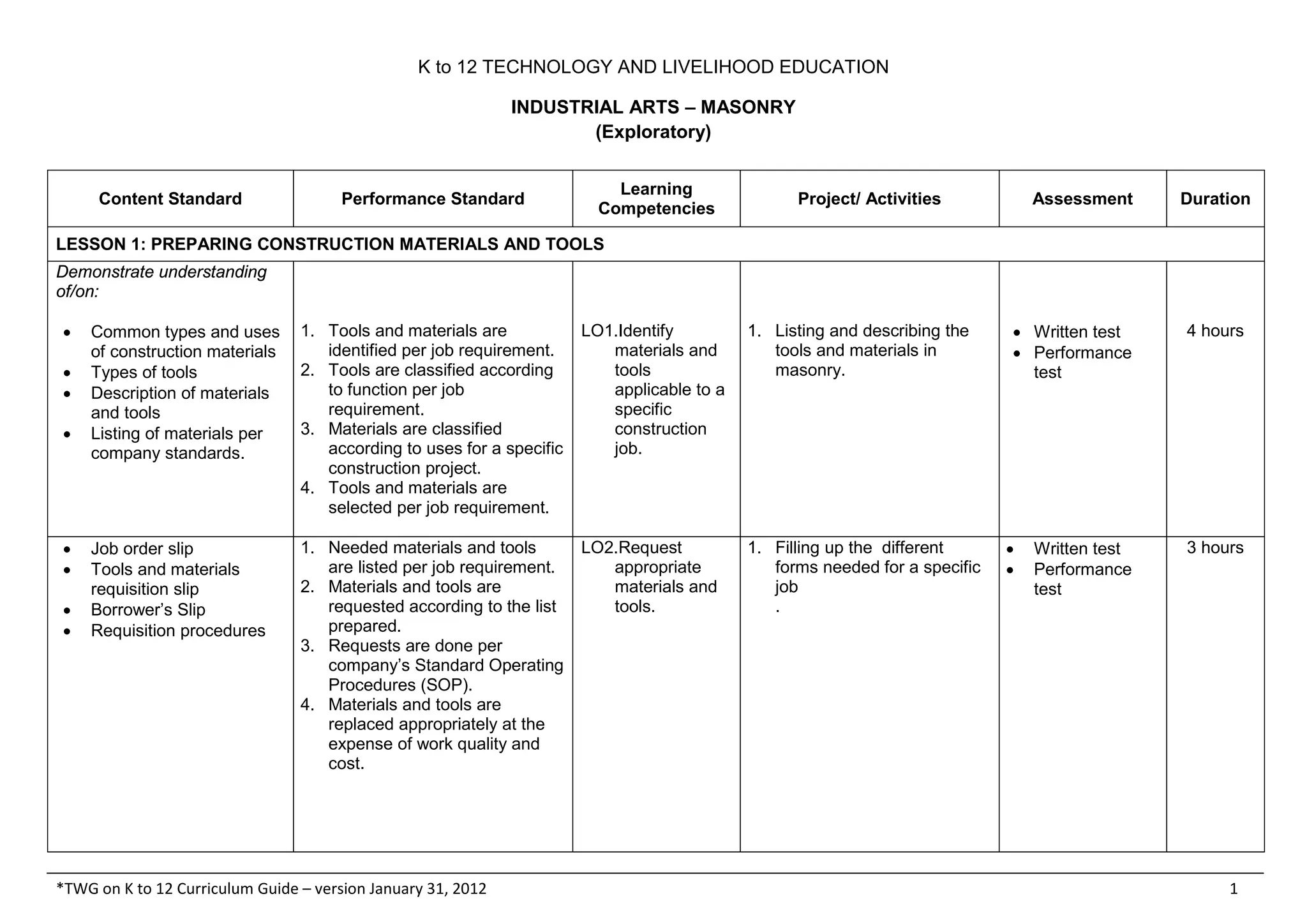

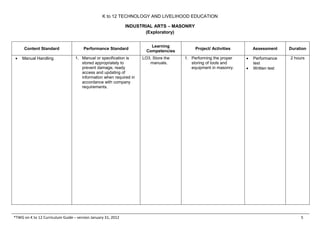

This document outlines a curriculum for an exploratory course on masonry. It includes 5 lessons that cover the following topics:

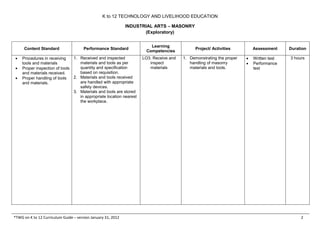

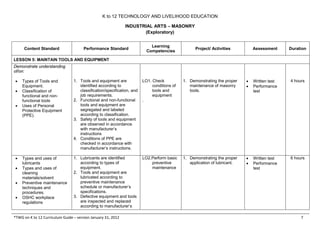

1. Preparing construction materials and tools, which teaches students to identify, classify, and select appropriate tools and materials for jobs.

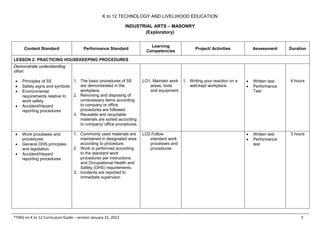

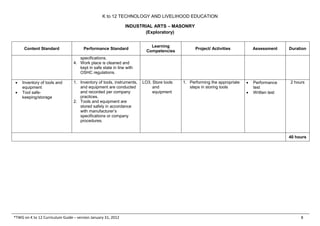

2. Practicing housekeeping procedures, including maintaining work areas using 5S principles and following safety and reporting procedures.

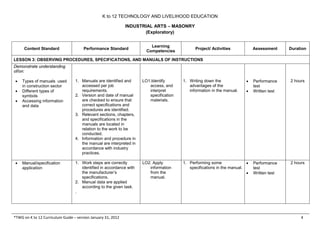

3. Observing procedures, specifications, and manuals of instructions, such as identifying, interpreting, and applying information from manuals.

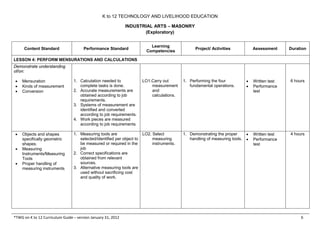

4. Performing mensurations and calculations needed for tasks.

5. Maintaining tools and equipment, like checking conditions, performing preventative maintenance, and storing tools properly.

The