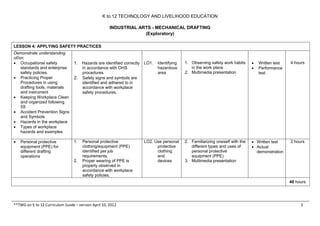

This document provides the curriculum guide for an exploratory course on Mechanical Drafting for K to 12 in the Philippines. It outlines 4 lessons that cover key topics including drafting materials and tools, measurement, interpreting drawings, and safety practices. The guide defines the content and performance standards, learning competencies, example projects and activities, and assessment methods for each lesson. The lessons are designed to teach students about drafting fundamentals and safety in 40 total hours through hands-on activities, demonstrations, tests, and other assessments.