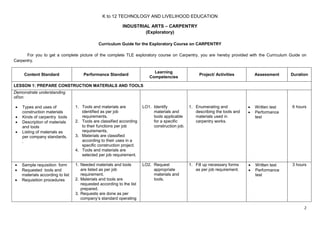

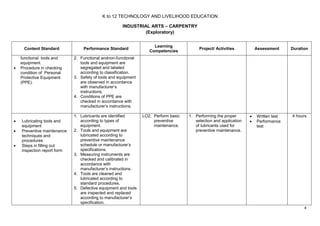

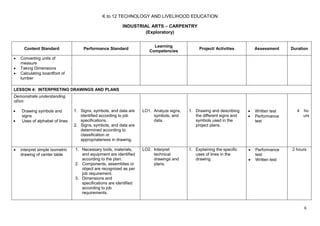

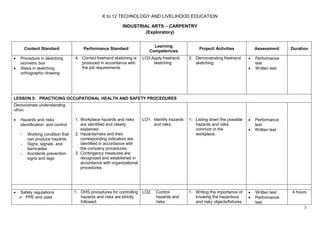

The document is a curriculum guide for an exploratory course on carpentry. It outlines 5 lessons that cover key topics like preparing construction materials and tools, maintaining tools and equipment, measurement and calculation, interpreting drawings and plans, and occupational health and safety procedures. Each lesson identifies relevant content standards and performance standards, learning competencies, sample projects and activities, and an assessment and time duration. The guide provides a complete overview of the exploratory carpentry course content and assessments to help students understand the scope and requirements of the course.