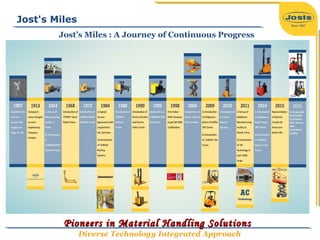

Jost's Engineering Company Limited, an ISO 9001:2008 certified firm, has been a leader in material handling solutions in India for over a century, focusing on empowering industries with advanced technology. The company offers a range of stackers designed for various material handling needs, ensuring robustness, operational efficiency, and safety features. Jost's commitment to customer-centric solutions is evident through their extensive product range and emphasis on technological innovation.