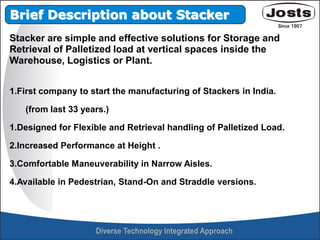

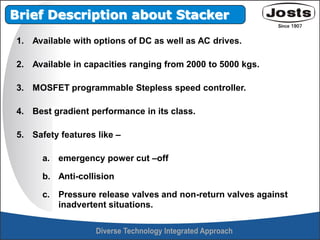

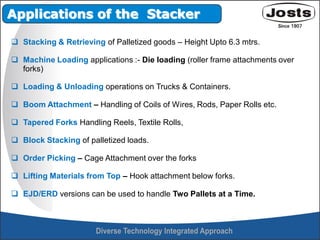

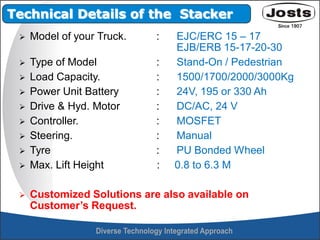

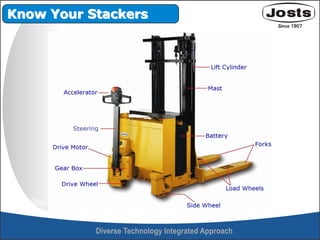

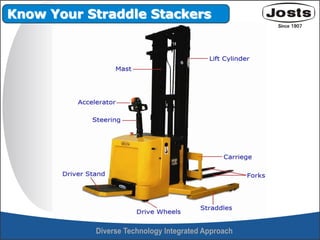

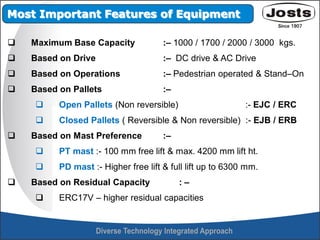

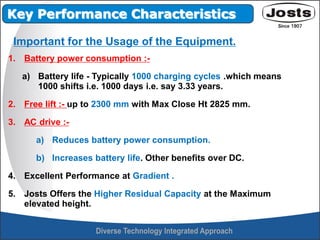

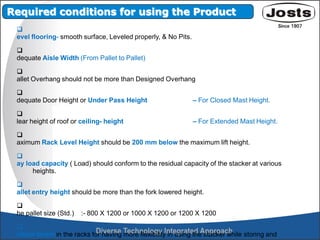

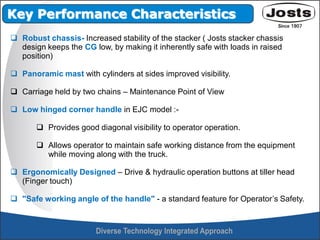

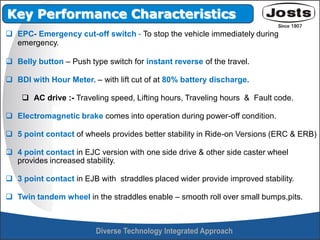

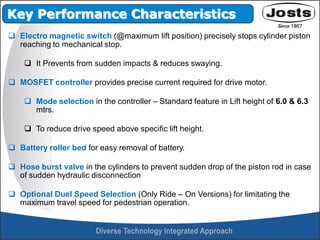

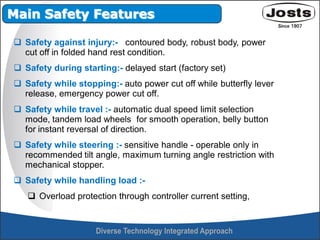

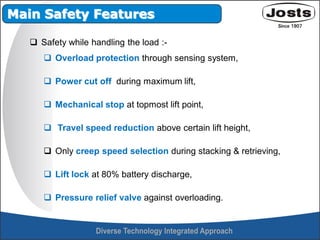

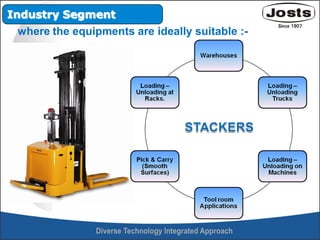

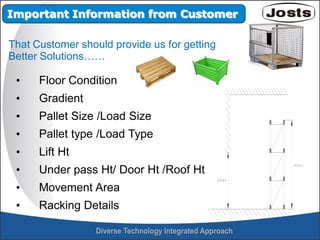

The document outlines the features and specifications of electric stackers designed for efficient handling of palletized loads in warehouses and logistics environments. It details various models available, including their capacities, drive options, performance characteristics, and safety features, as well as applications for stacking and retrieving goods. Additionally, it emphasizes the importance of proper operating conditions and safety measures to ensure optimal use of the equipment.