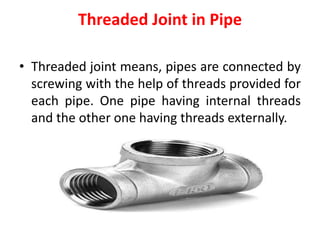

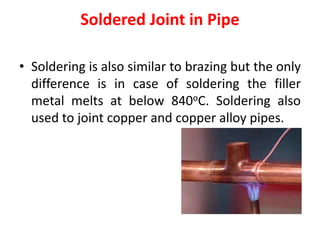

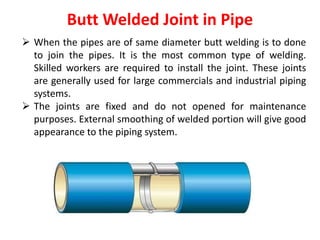

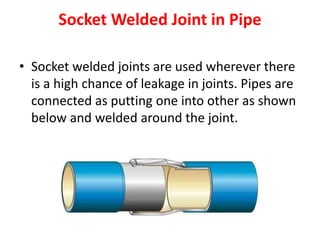

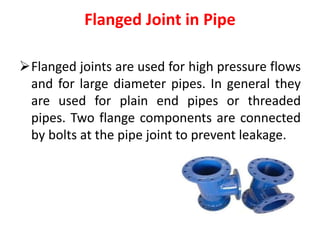

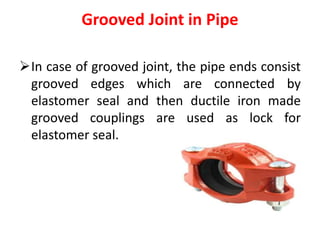

Different types of pipe joints are used to connect multiple water pipes and withstand pressure. These include threaded joints which connect pipes by screwing threads together, brazed joints which use molten filler above 840°C, and soldered joints which use filler below 840°C to join copper pipes. Other joint types are welded (butt and socket), flanged which connect plain or threaded pipes with bolts to prevent leaks, and grooved joints which connect grooved pipe ends with a seal and coupling. Each type is suited for different applications in water supply systems.