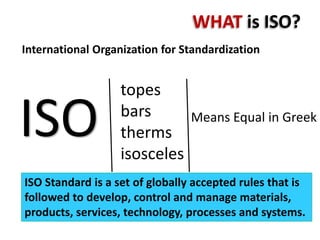

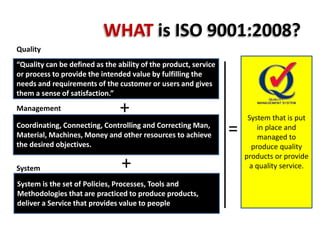

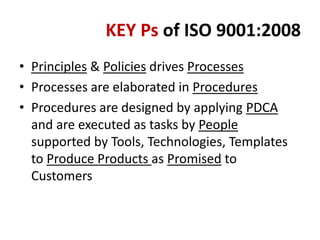

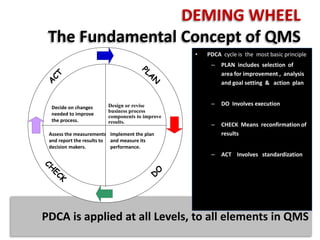

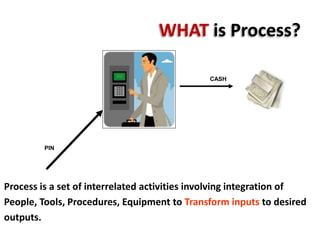

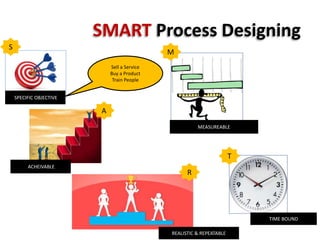

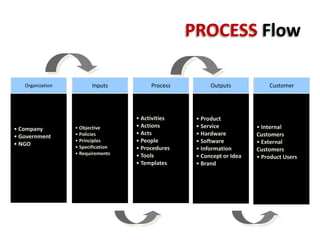

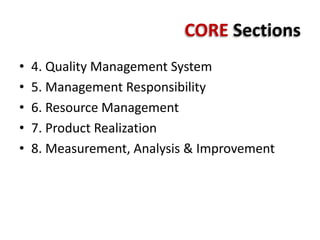

This document provides an overview of ISO 9001:2008. It discusses what ISO and ISO 9001 are, including that ISO 9001 establishes standards for quality management systems. It outlines the key aspects of a quality management system, including customer focus, leadership, and continual improvement. The core sections of ISO 9001 that establish requirements for the quality management system are described as management responsibility, resource management, product realization, measurement and improvement. The document emphasizes that ISO 9001 is implemented through establishing documented processes and procedures that are managed using the PDCA cycle of continual improvement.