The document discusses the economic order quantity (EOQ) P model for inventory management. The P model involves reviewing inventory levels and placing replenishment orders at fixed time intervals. Some key points:

- Inventory is reviewed and orders placed at predetermined times, like every 10 days for a sales rep.

- It is used for bulk materials and services that are replenished regularly at set periods.

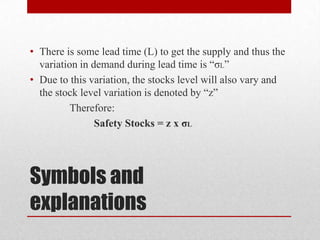

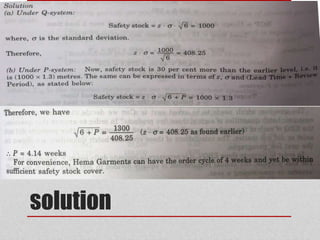

- Safety stock accounts for variability in demand and lead times to ensure a certain service level of demand is met.

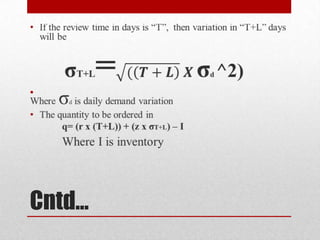

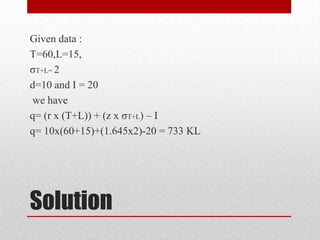

- Formulas show how to calculate order quantity factoring in demand, lead time variability, safety stock level, and other variables.

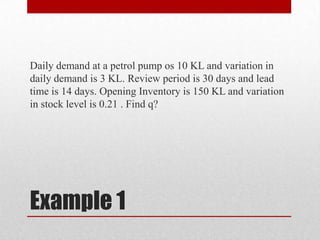

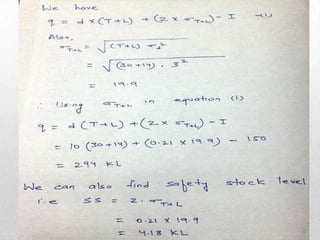

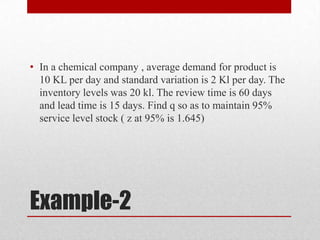

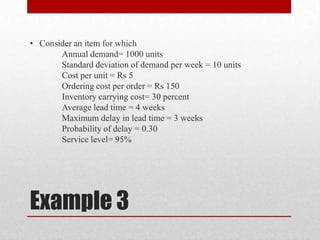

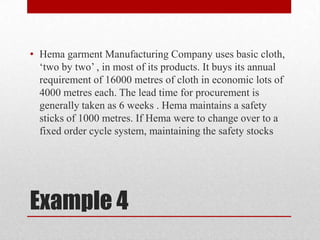

- Several examples demonstrate applying the P model concepts and formulas to sample inventory