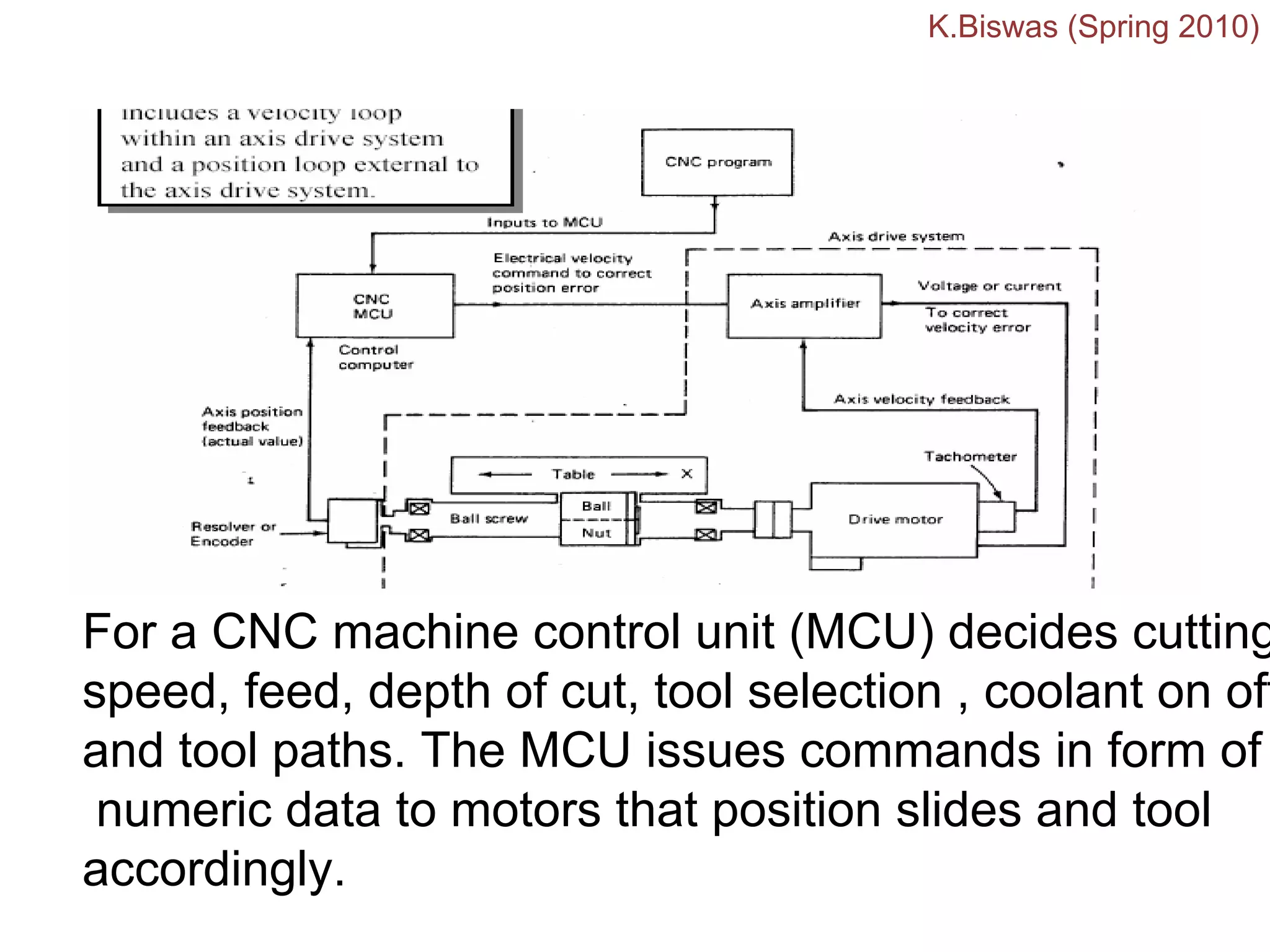

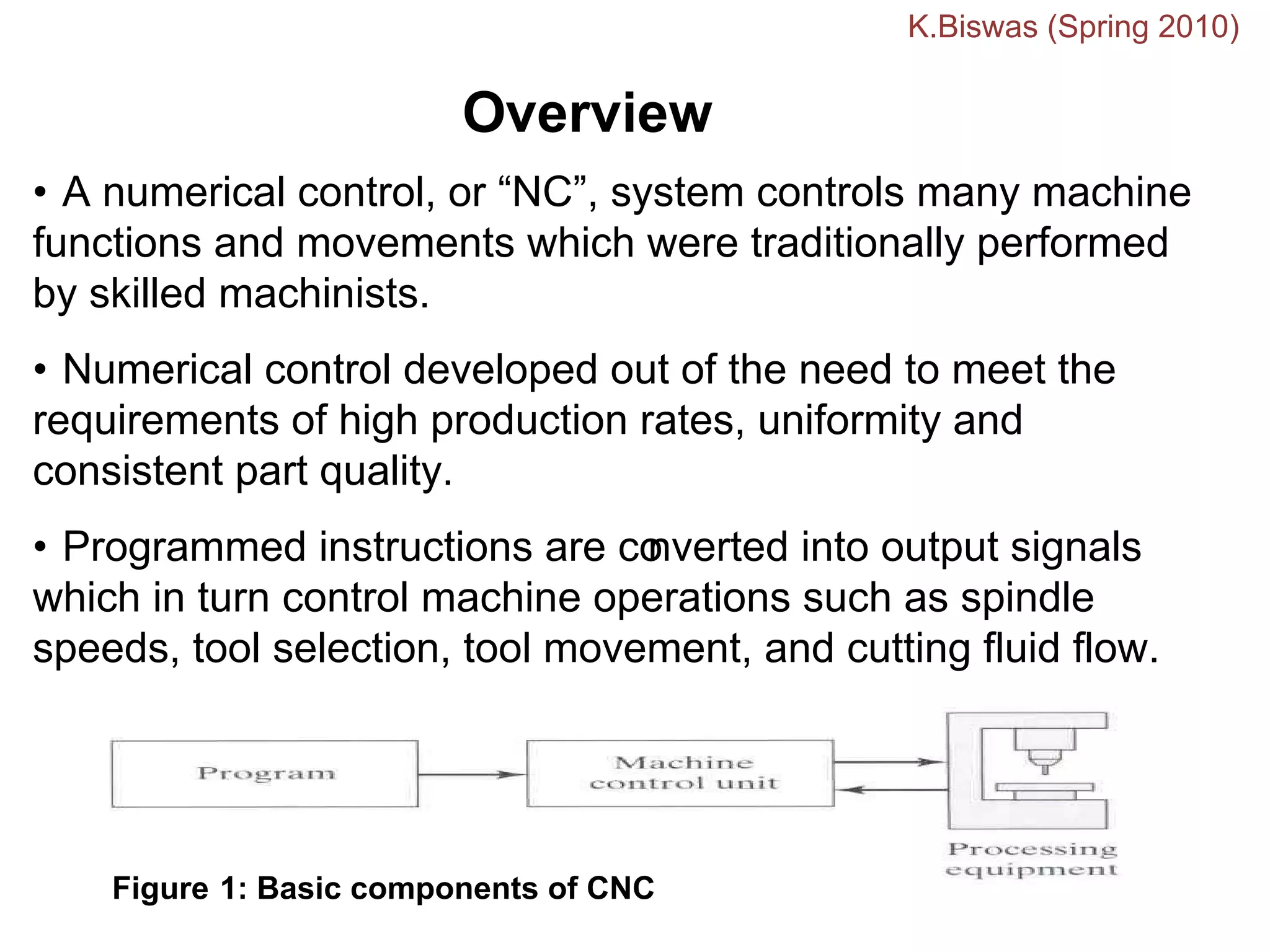

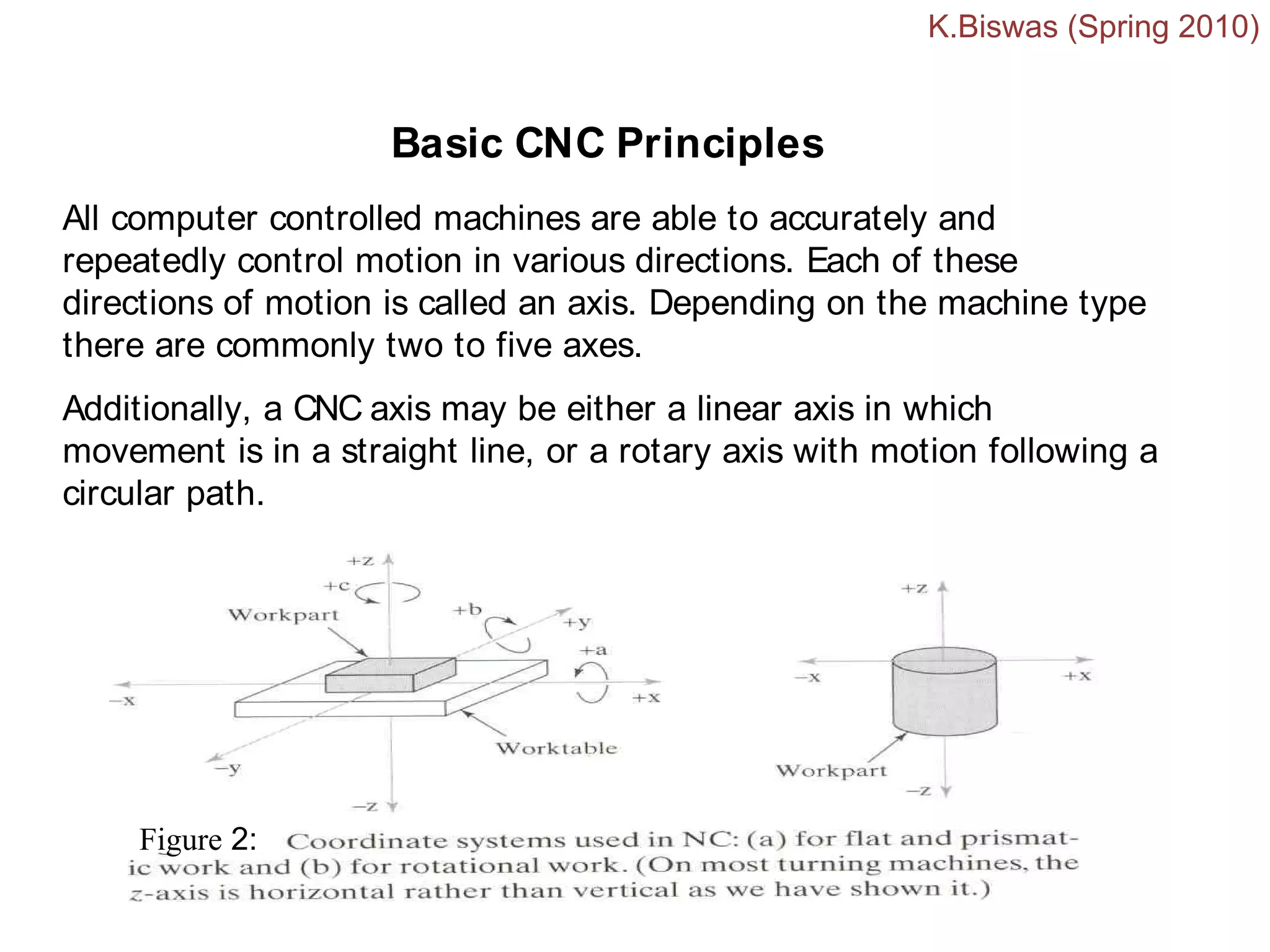

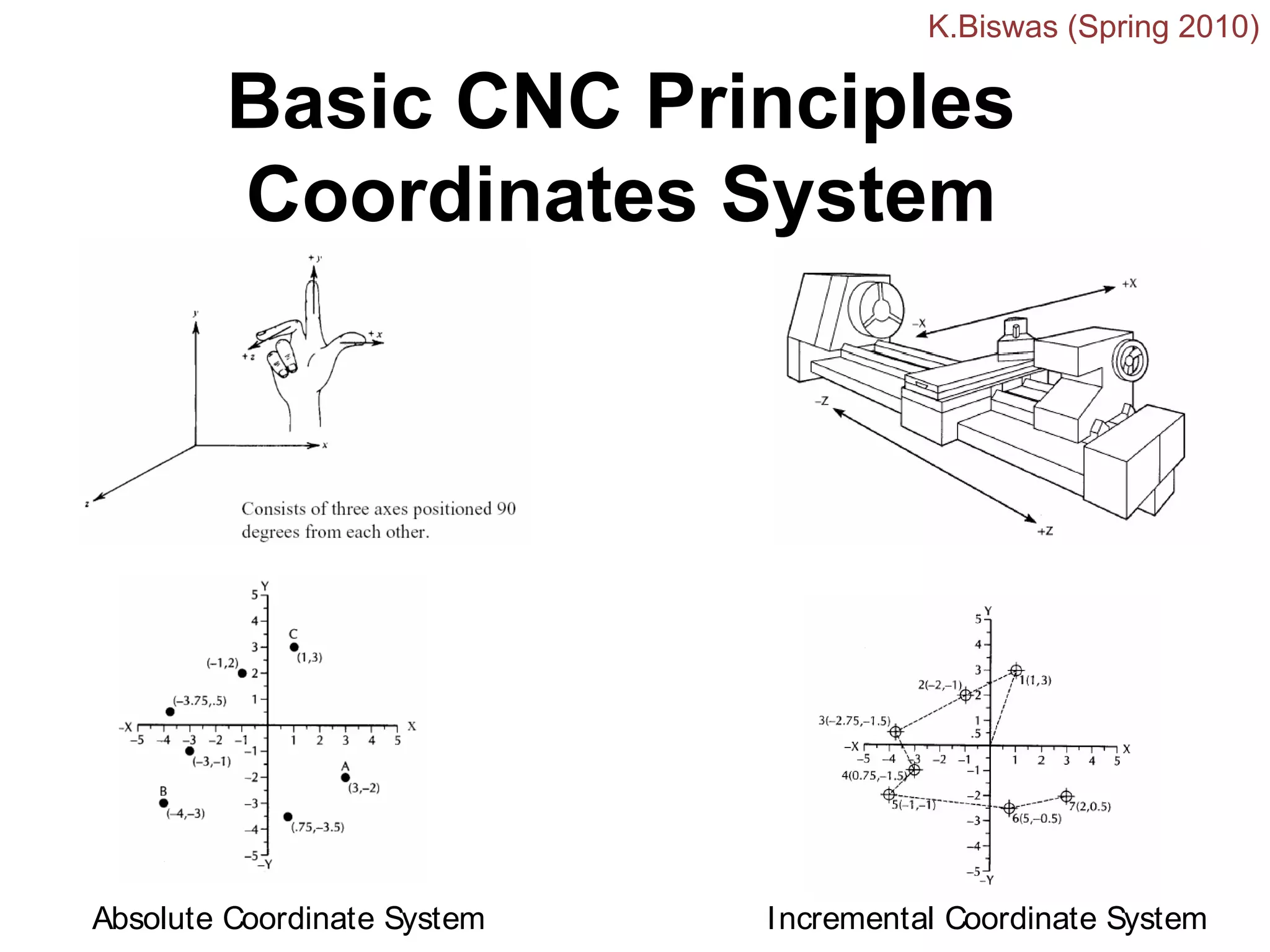

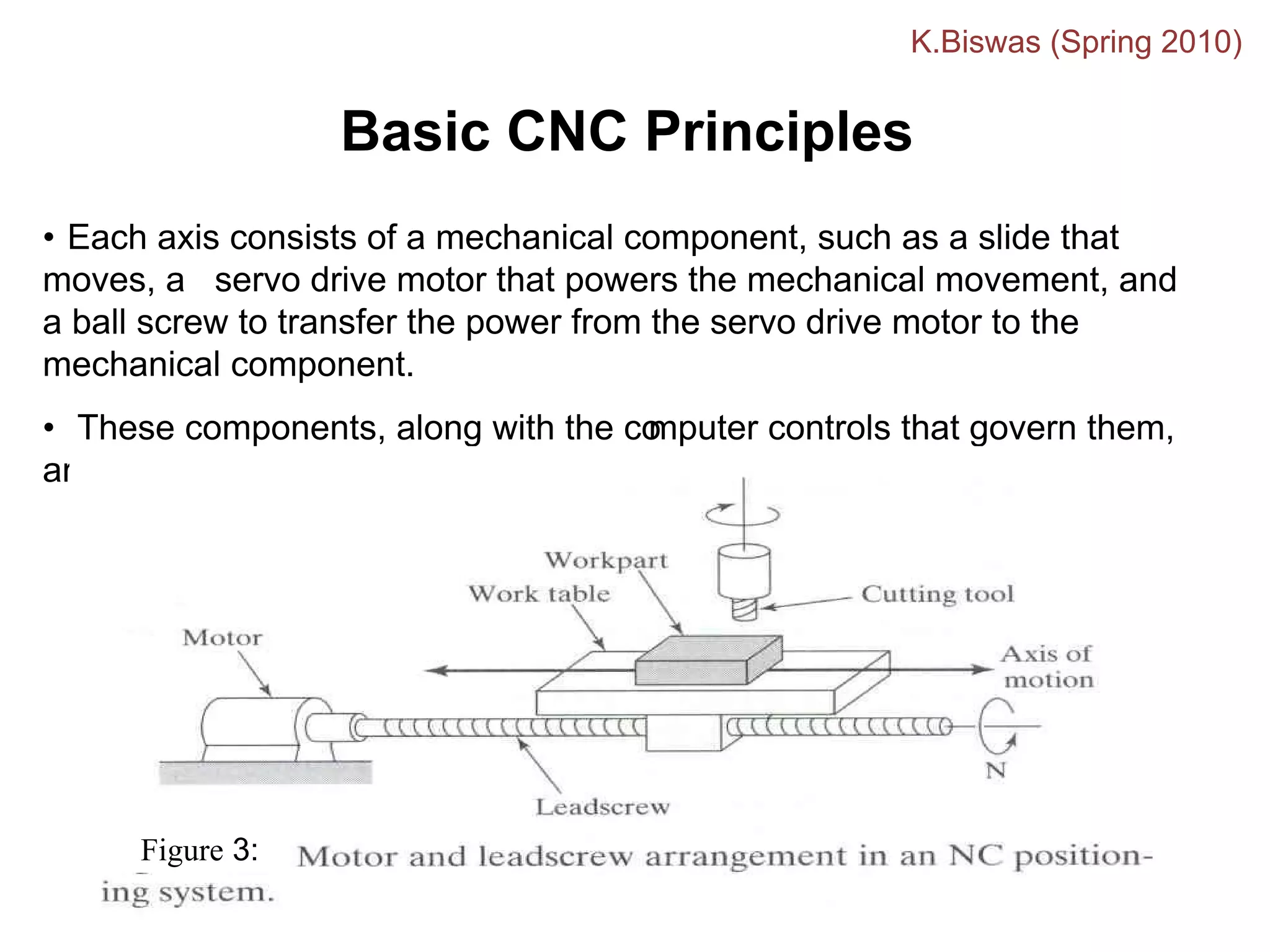

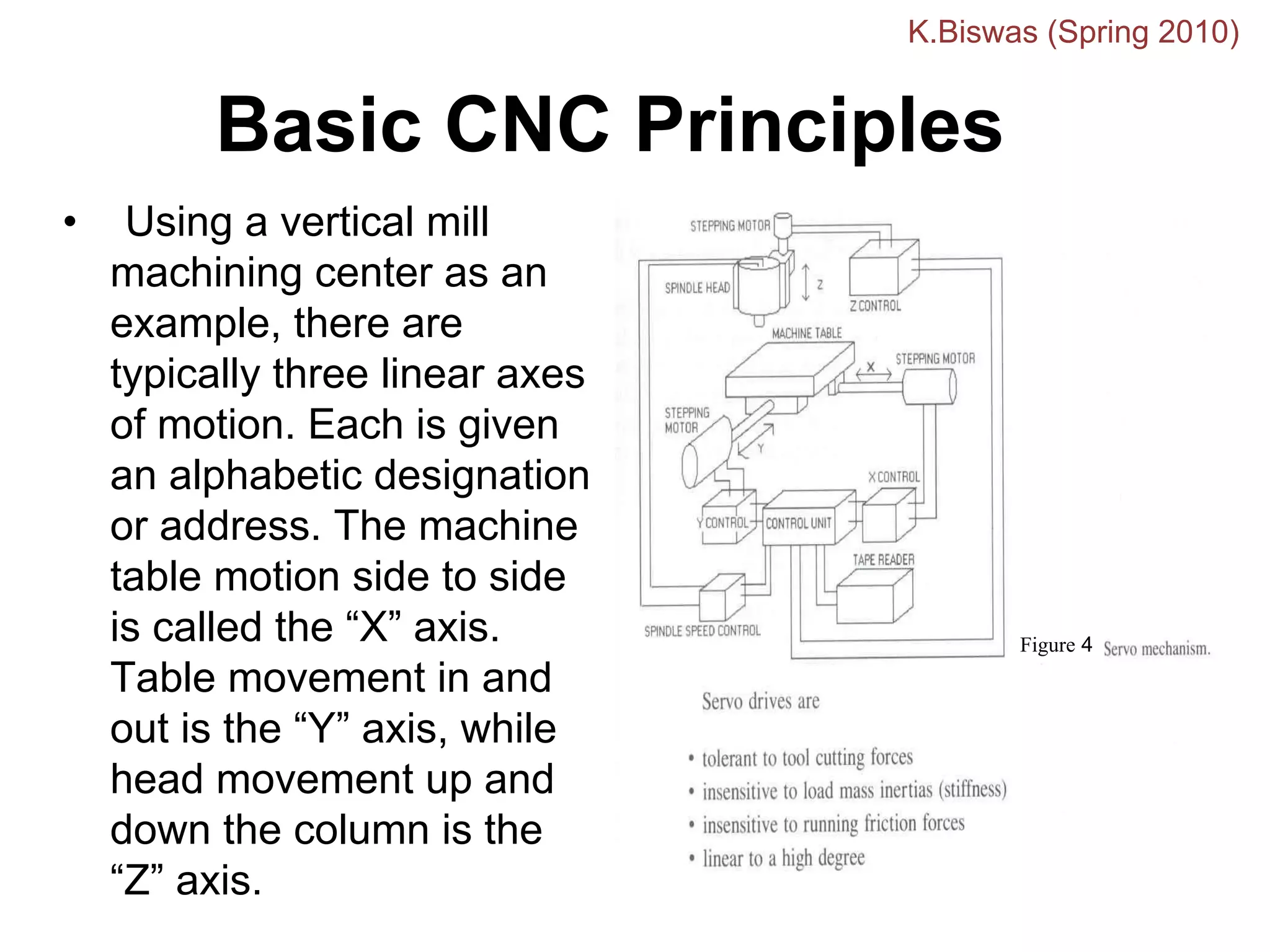

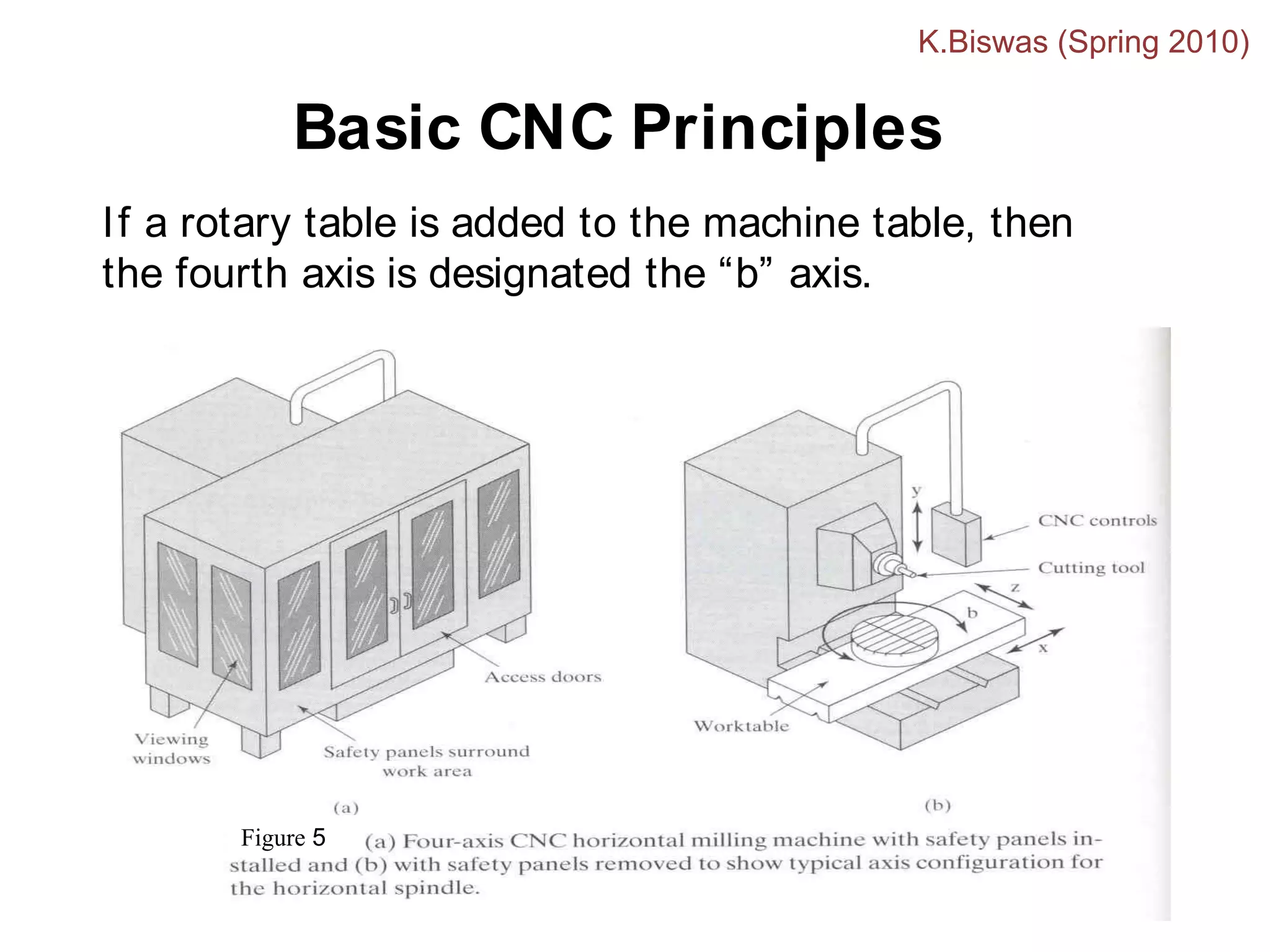

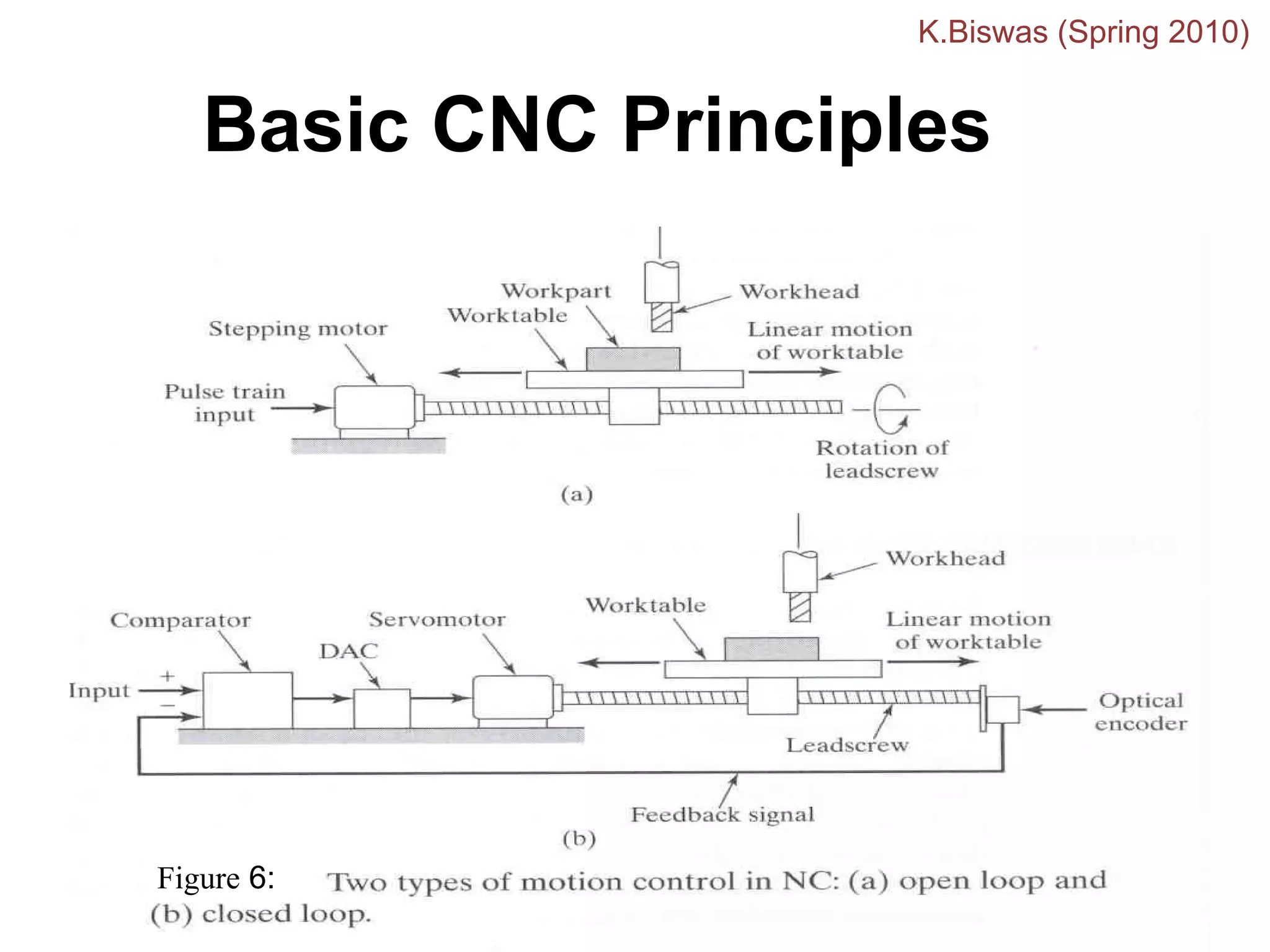

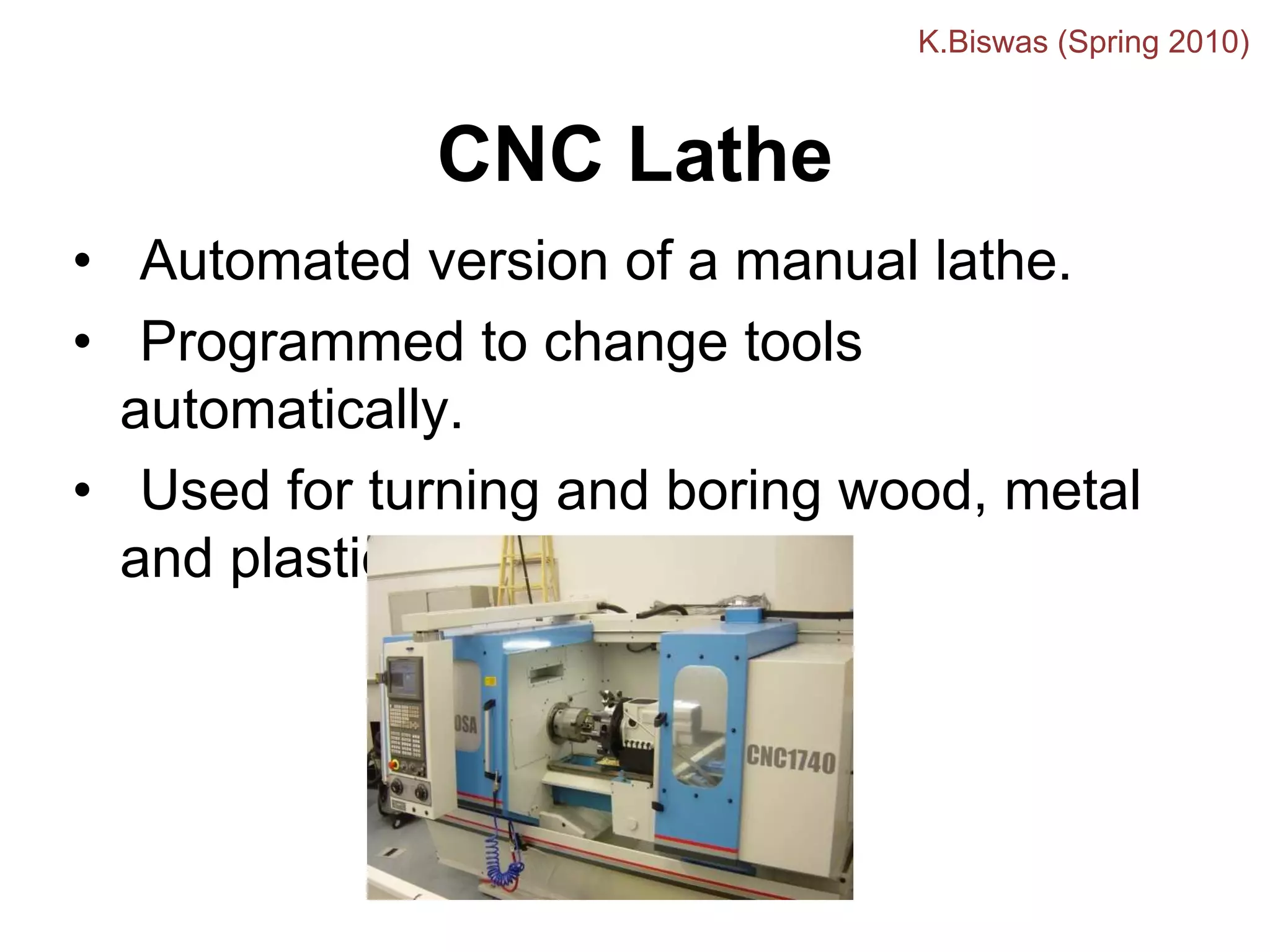

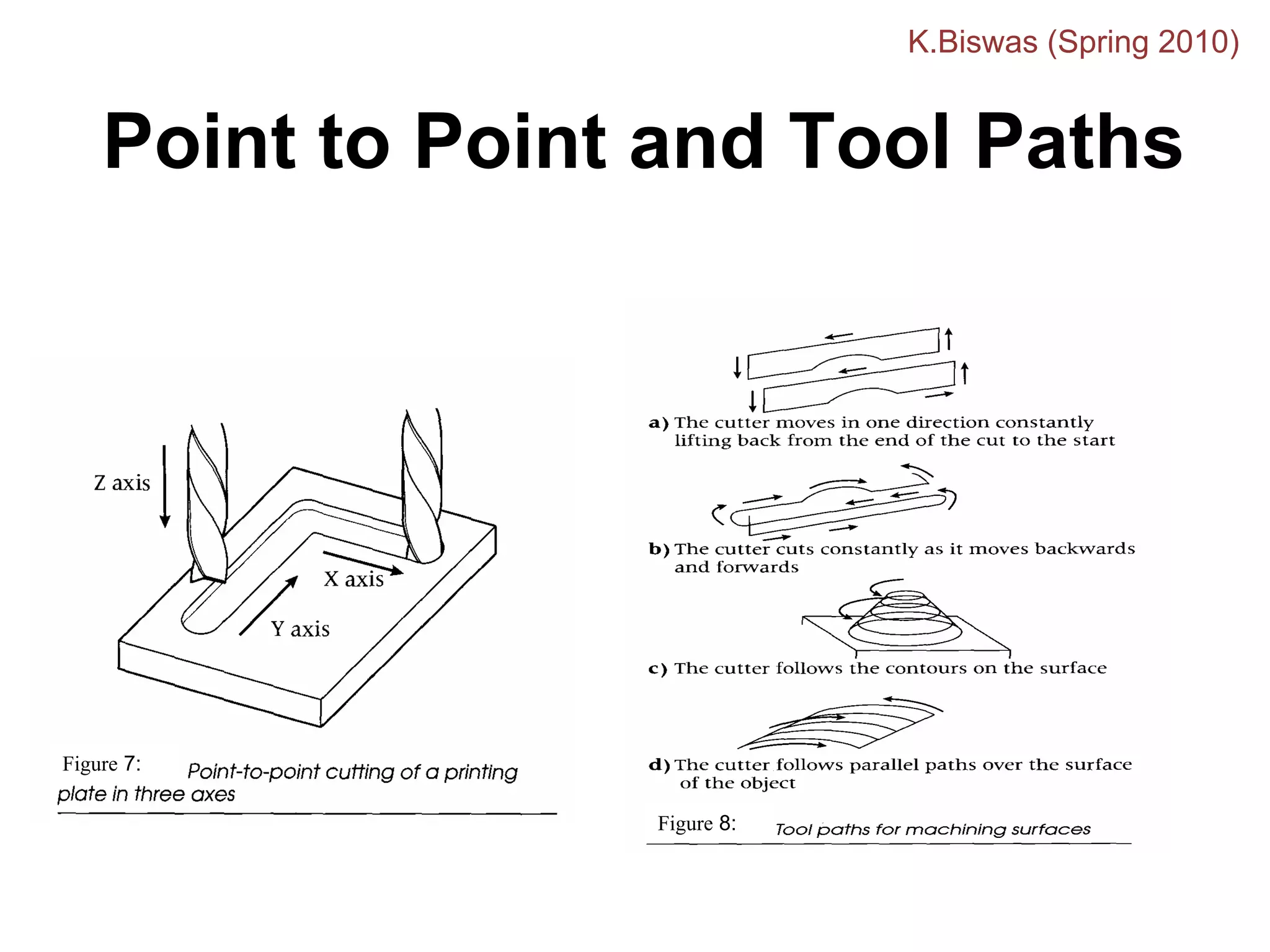

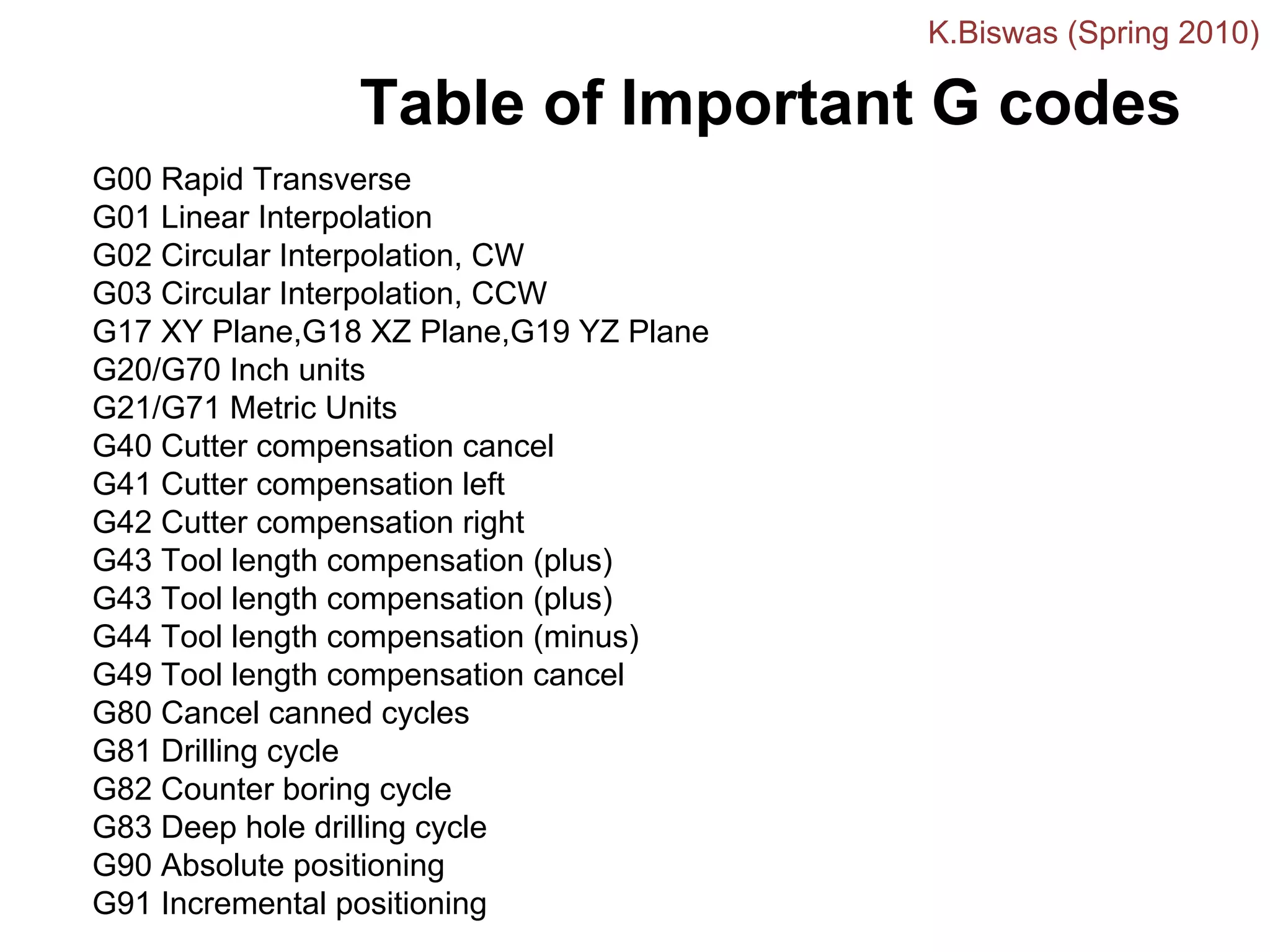

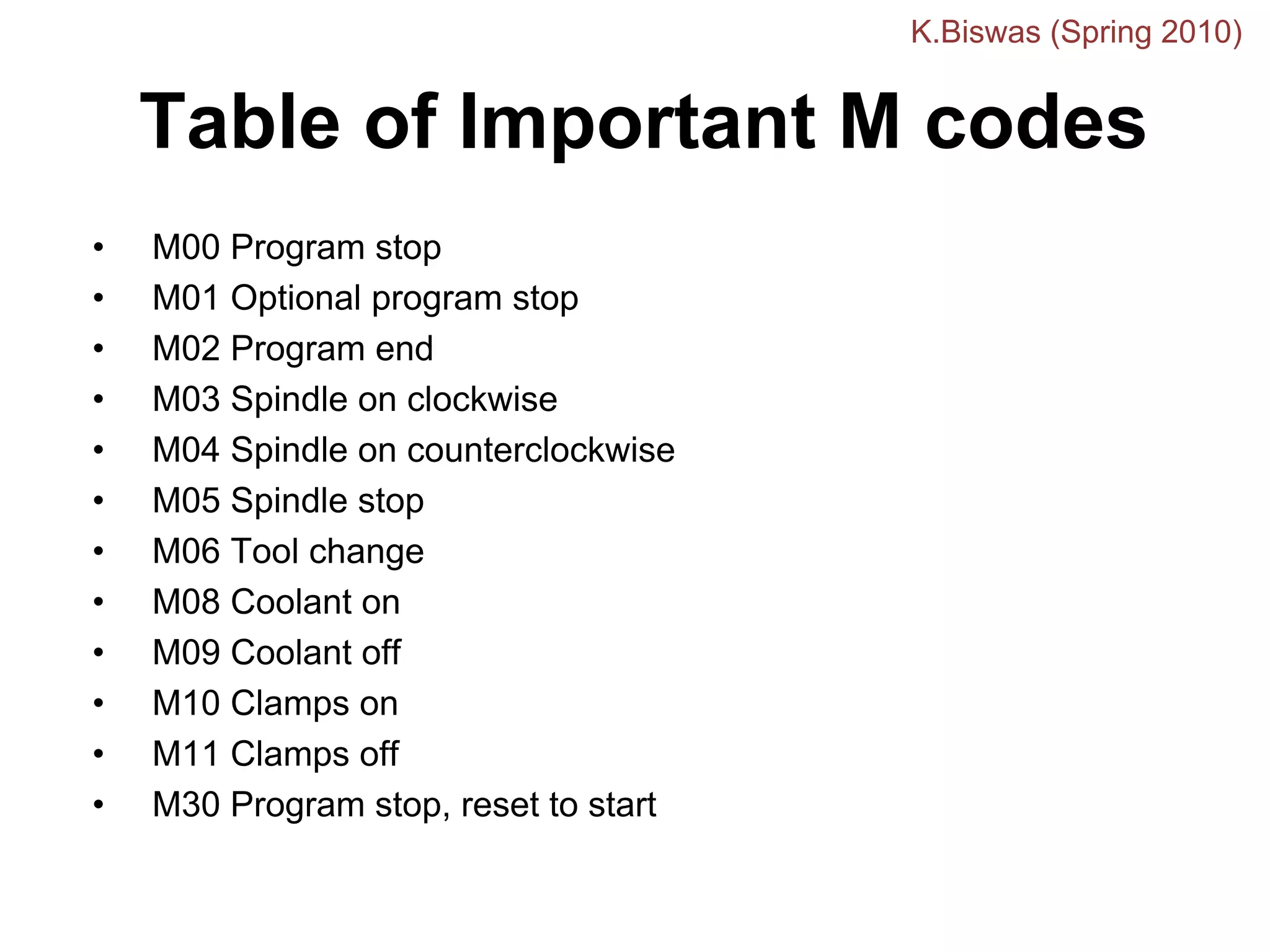

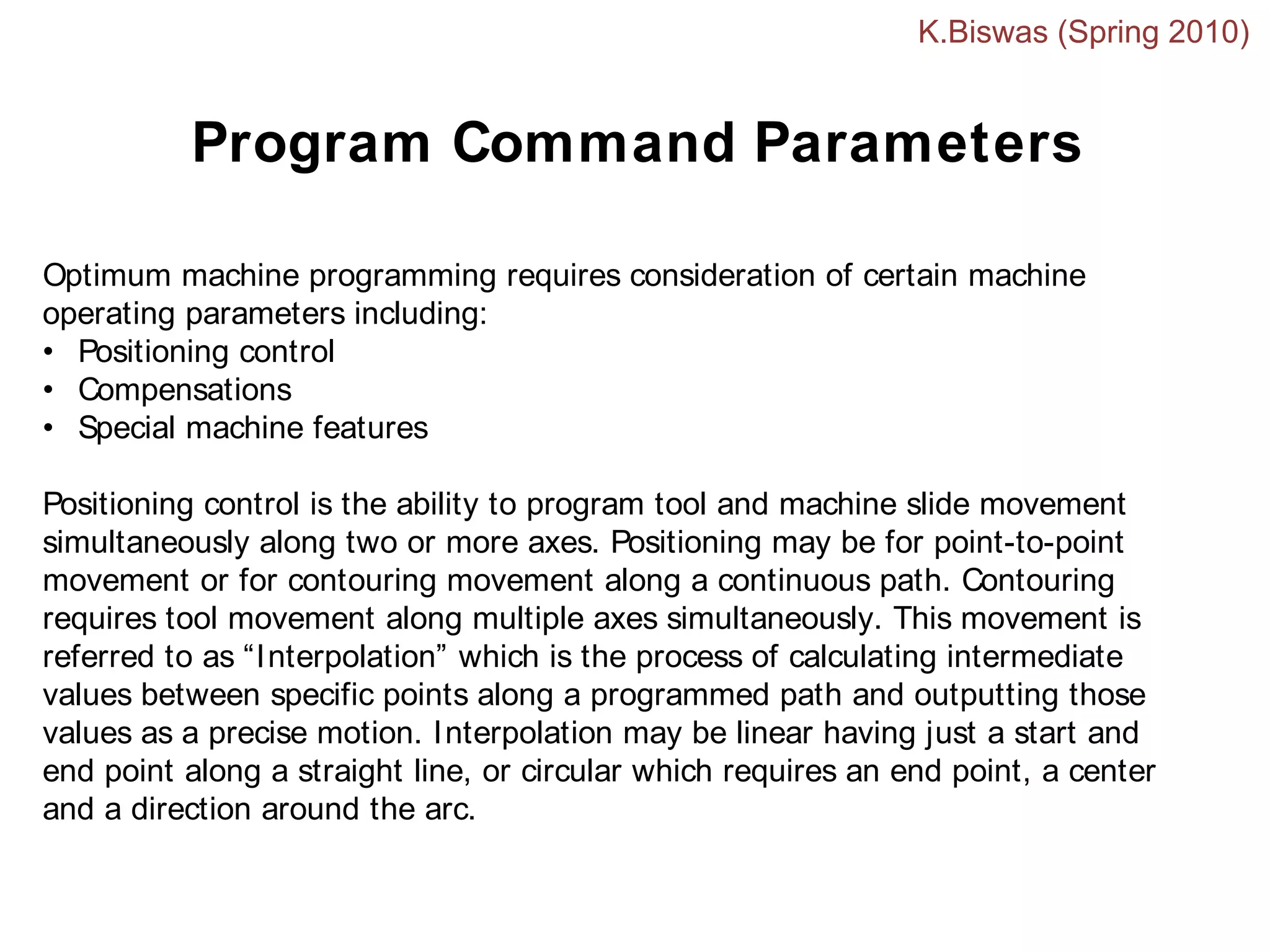

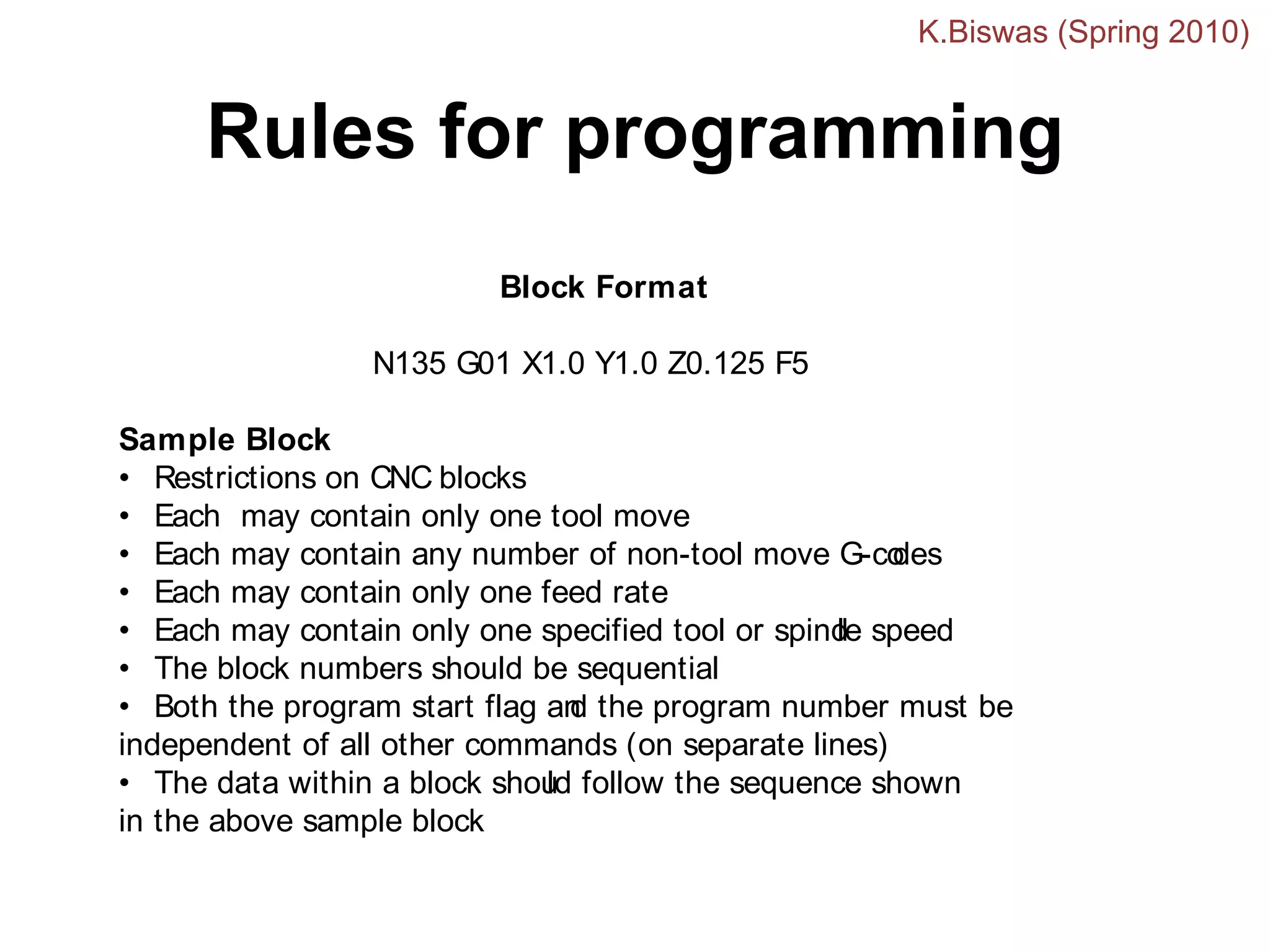

This document provides an introduction and overview of CNC (computer numeric control) machining. It discusses what CNC machines are, how they work by controlling slide movements with computer programs, and the basic components and principles of CNC like axes, coordinate systems, and motion control. It also covers CNC programming basics including G and M codes, tool paths, advantages and disadvantages of CNC, common machine types, and how CAD/CAM systems impact CNC technology.