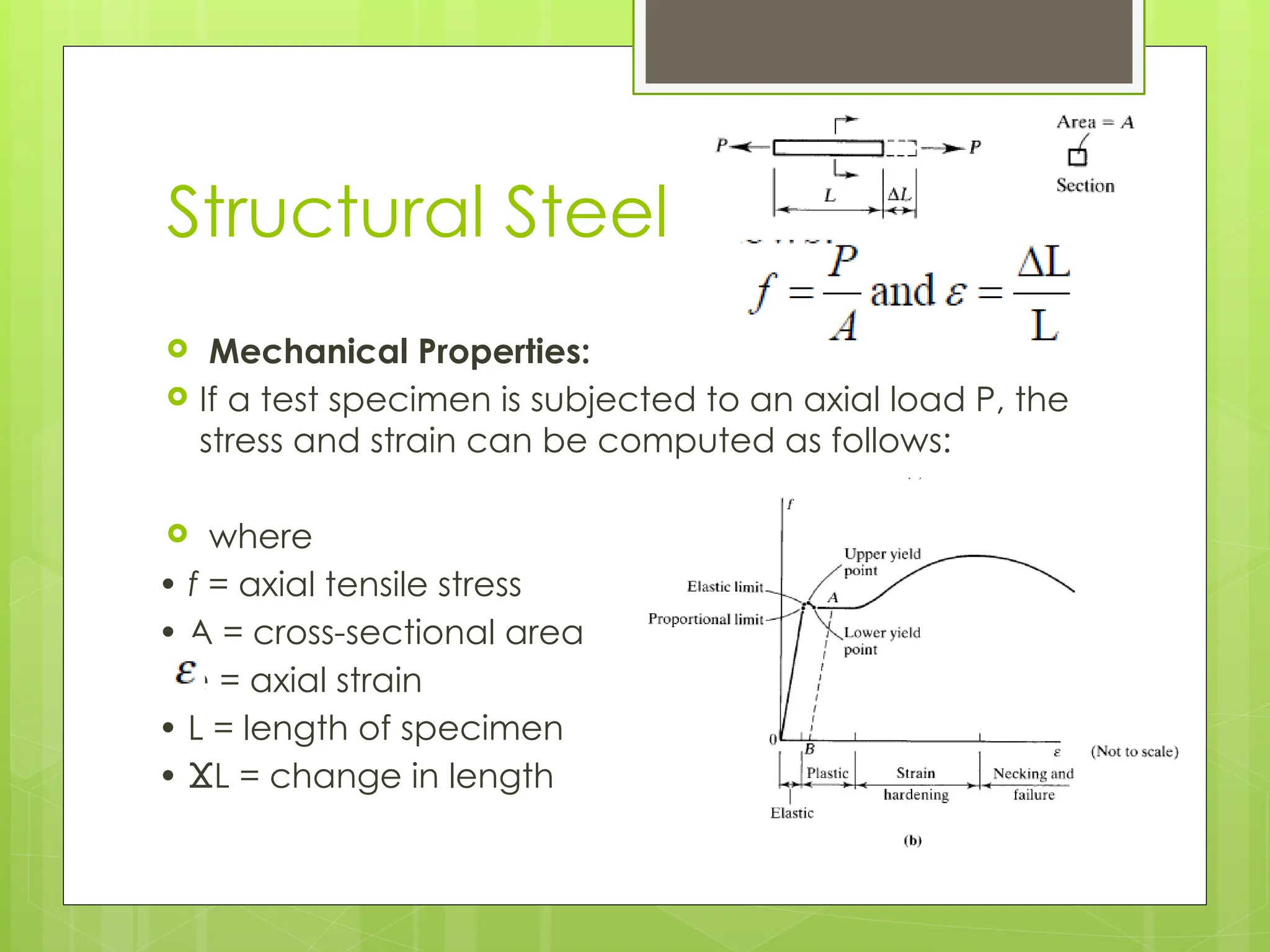

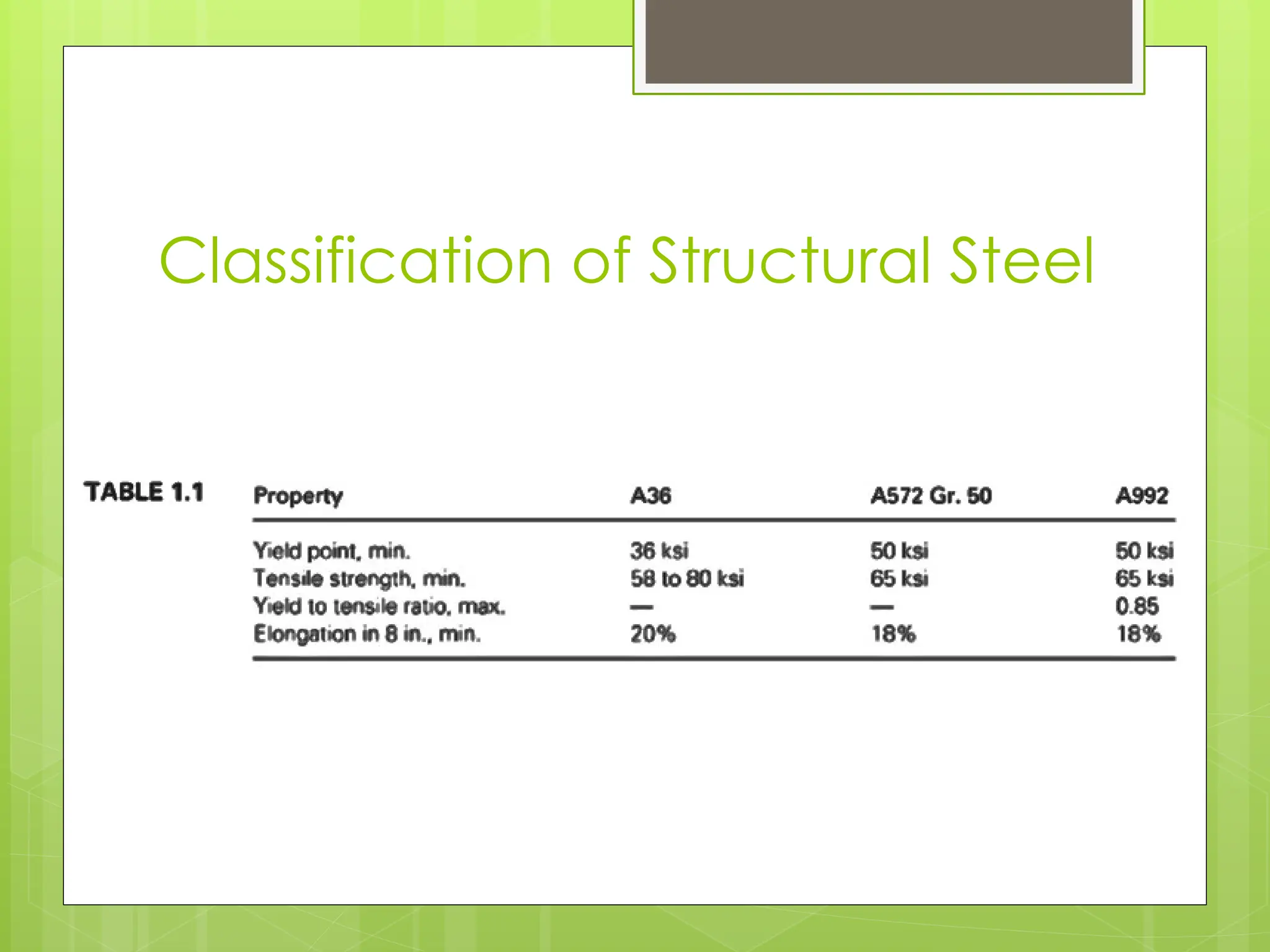

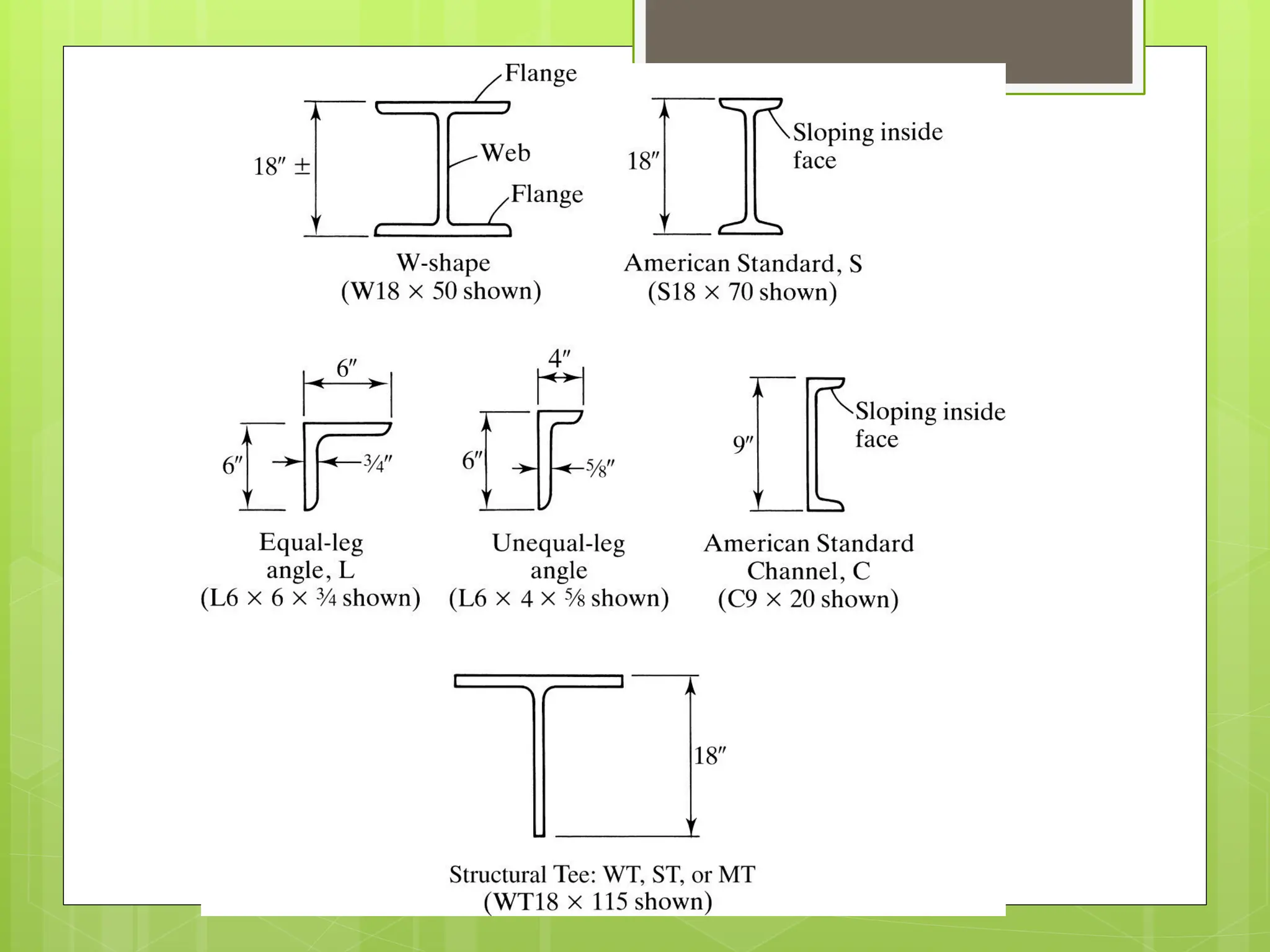

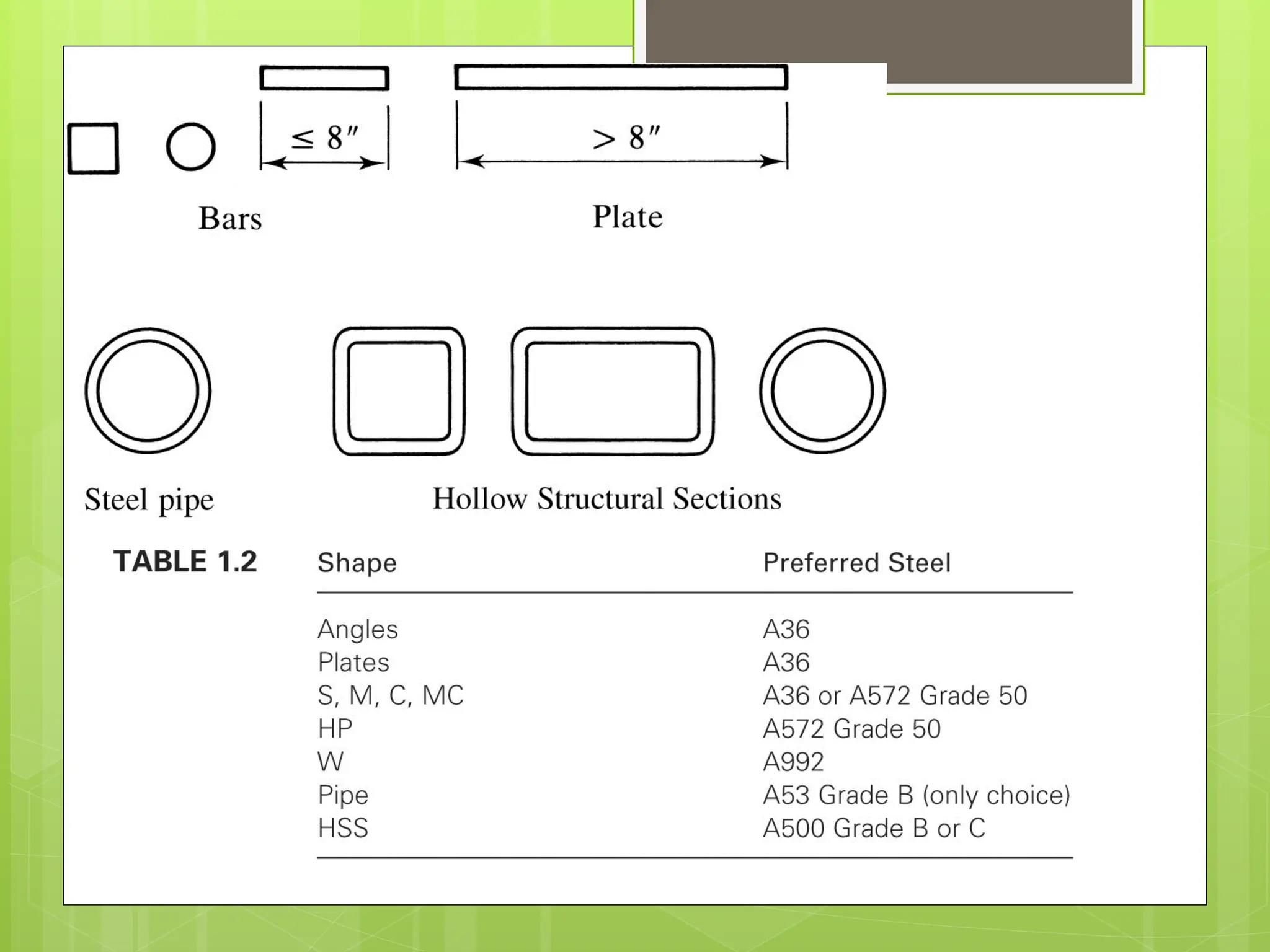

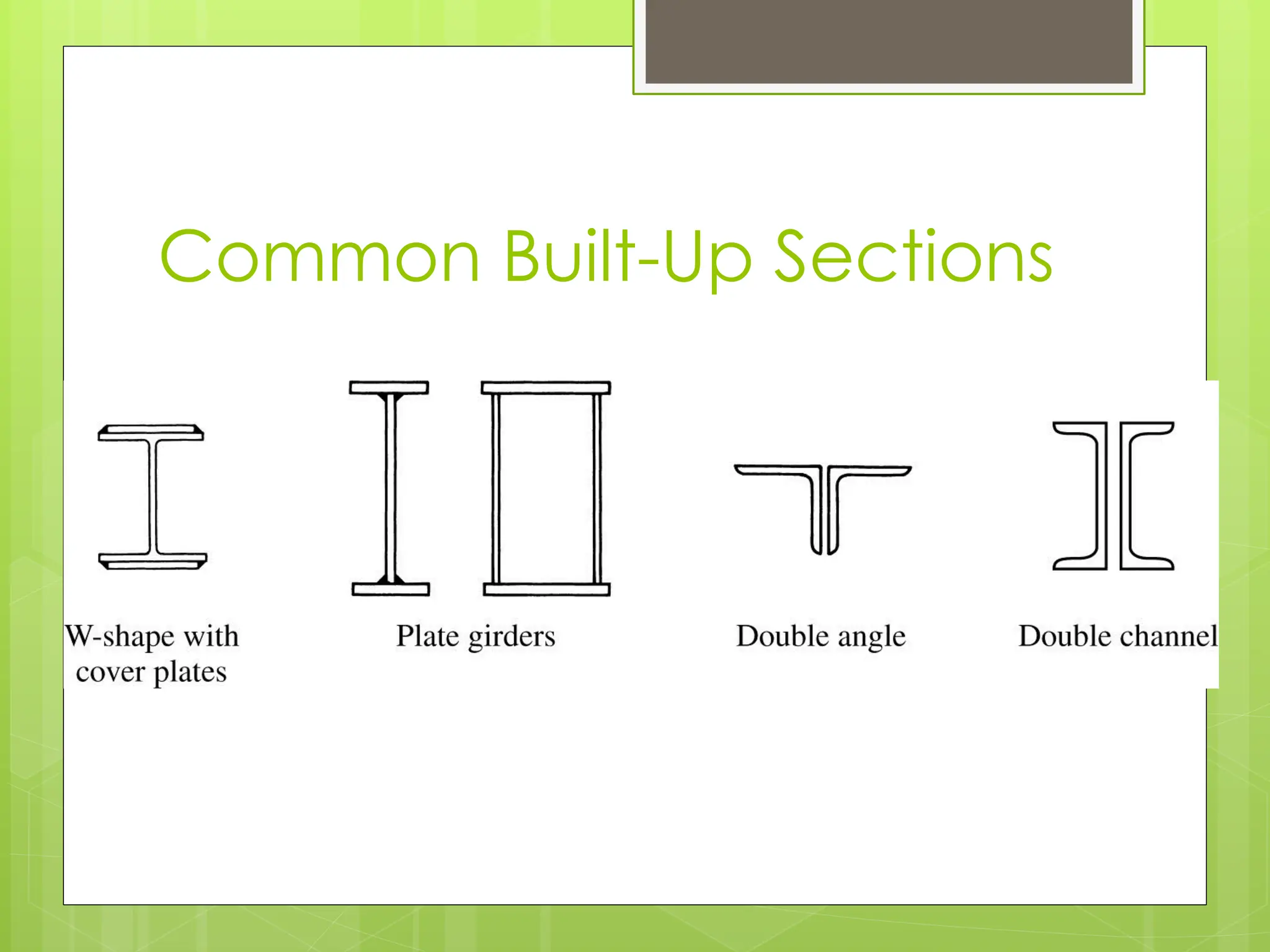

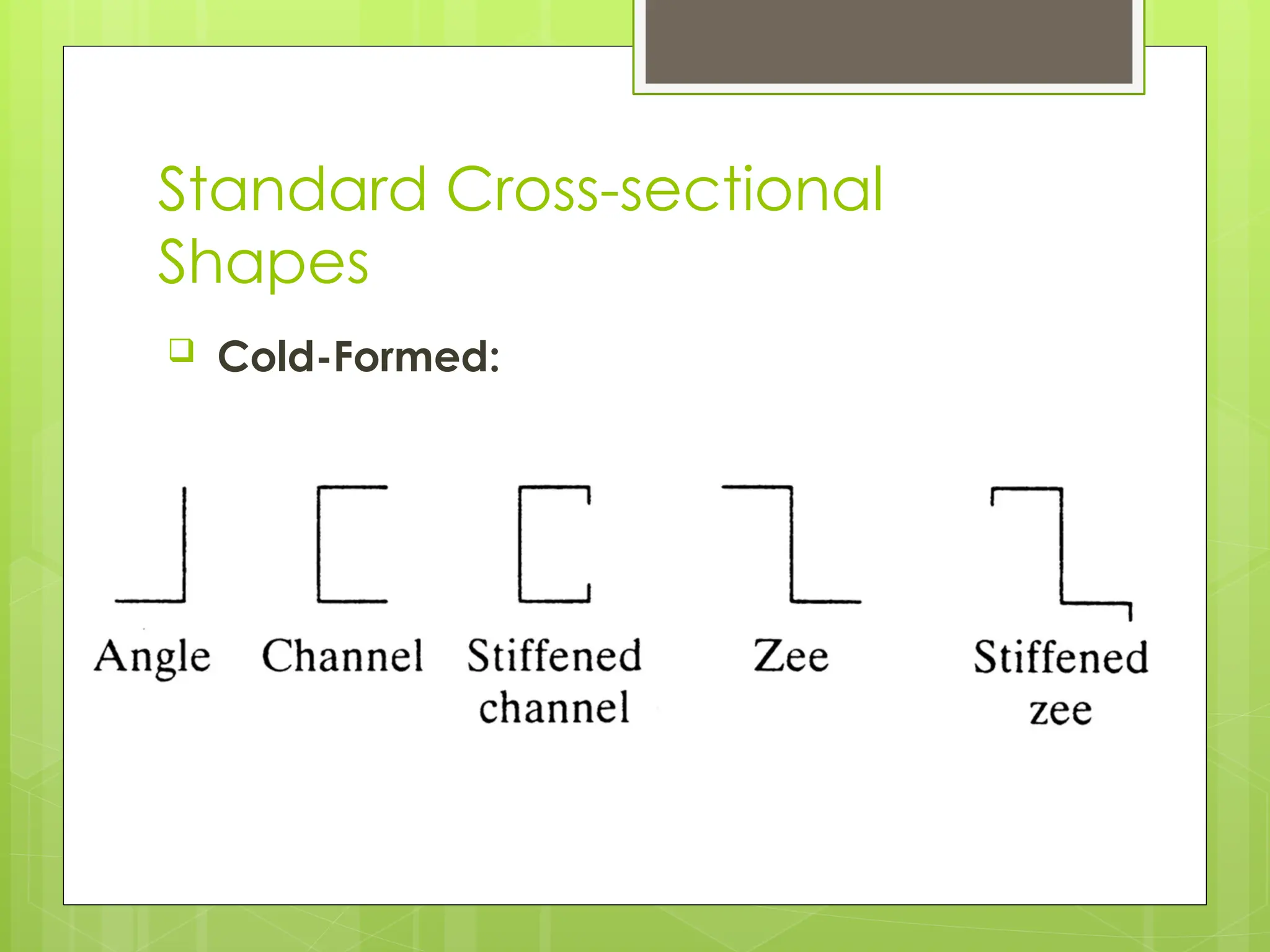

The document outlines the principles of structural steel design, detailing advantages and disadvantages of using steel, as well as the design process which includes load determination, structural analysis, and compliance with building codes. It emphasizes the importance of safety, serviceability, and economy in design responsibilities while discussing various types of loads that structures may encounter. Additionally, it covers material properties, classifications of structural steel, standard cross-sectional shapes, and references for further reading.