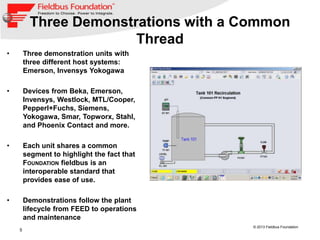

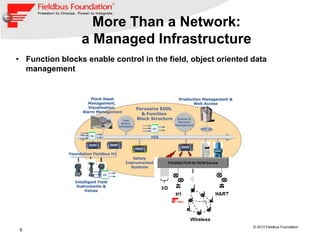

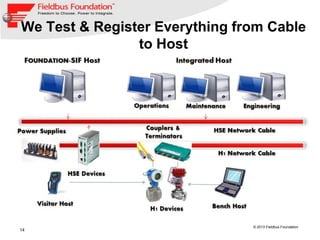

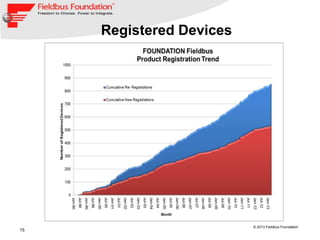

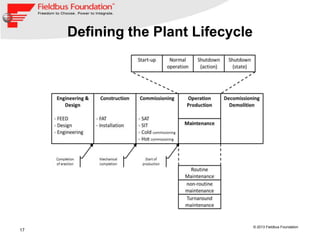

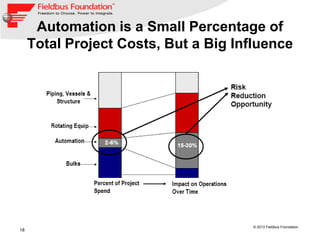

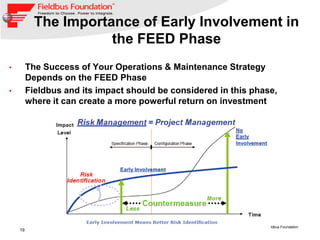

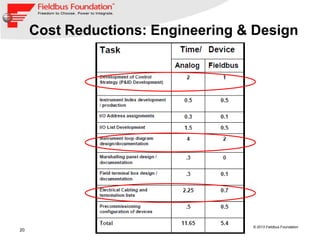

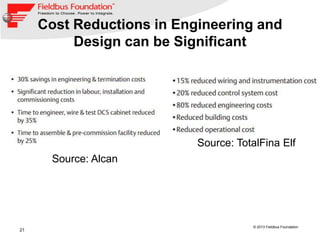

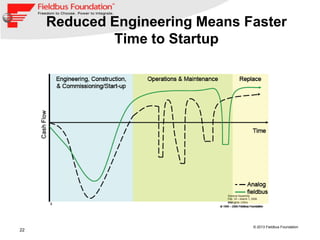

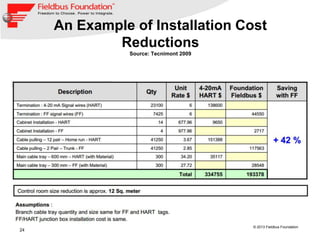

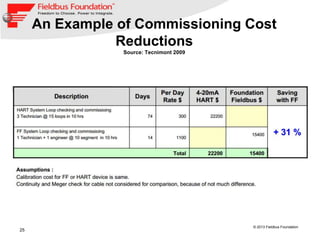

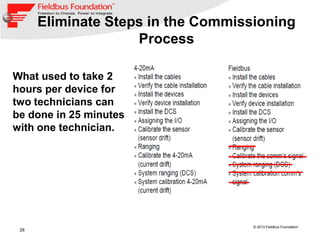

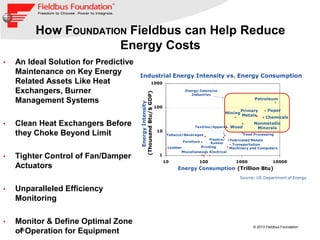

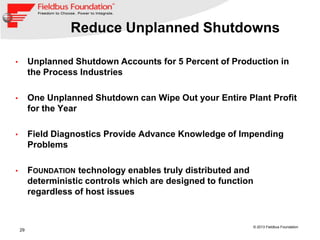

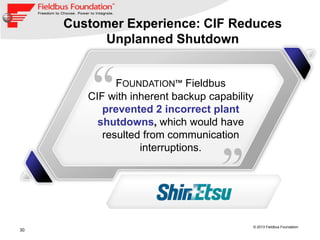

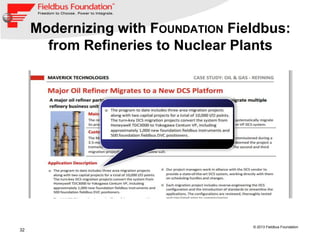

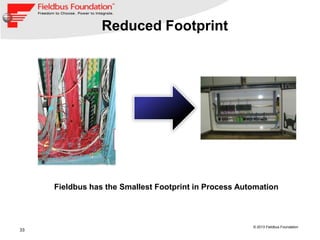

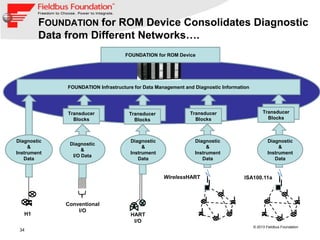

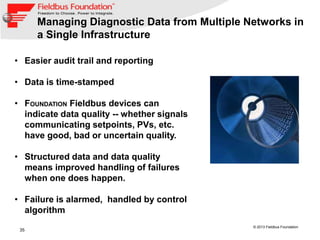

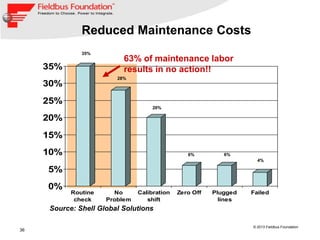

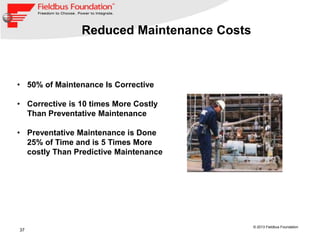

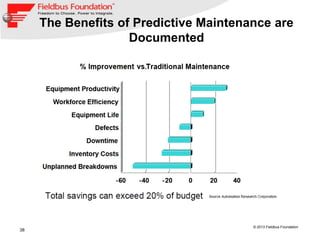

This document discusses the benefits of FOUNDATION fieldbus technology across the entire plant lifecycle from engineering to operations. It highlights cost savings from reduced engineering costs, faster commissioning, improved maintenance through predictive diagnostics, and the ability to modernize aging automation infrastructure. Fieldbus provides interoperability, standardized diagnostics, and a scalable architecture to integrate new and legacy devices for improved productivity.