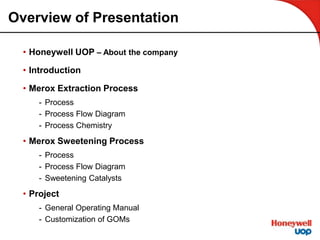

Anshul Bhandari completed an internship project at Honeywell UOP to develop General Operating Manuals (GOMs) for Merox extraction and sweetening processes. The GOMs provide operating instructions and procedures to help refineries safely operate these units. Anshul customized master GOMs for three client plants by editing plant-specific details, operating variables, equipment information, and startup/shutdown steps. The customized GOMs will help the clients develop standard operating procedures for their Merox units.