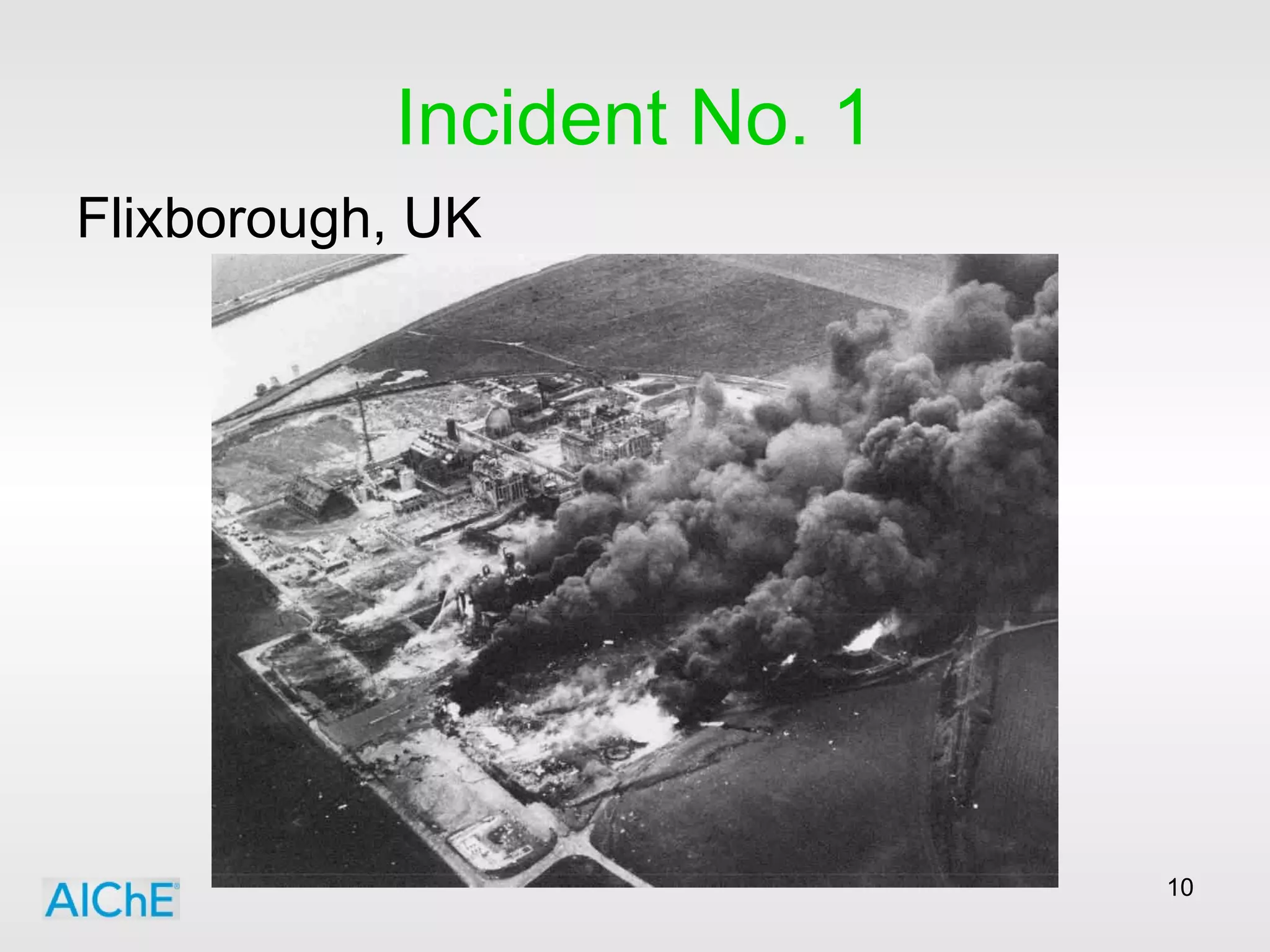

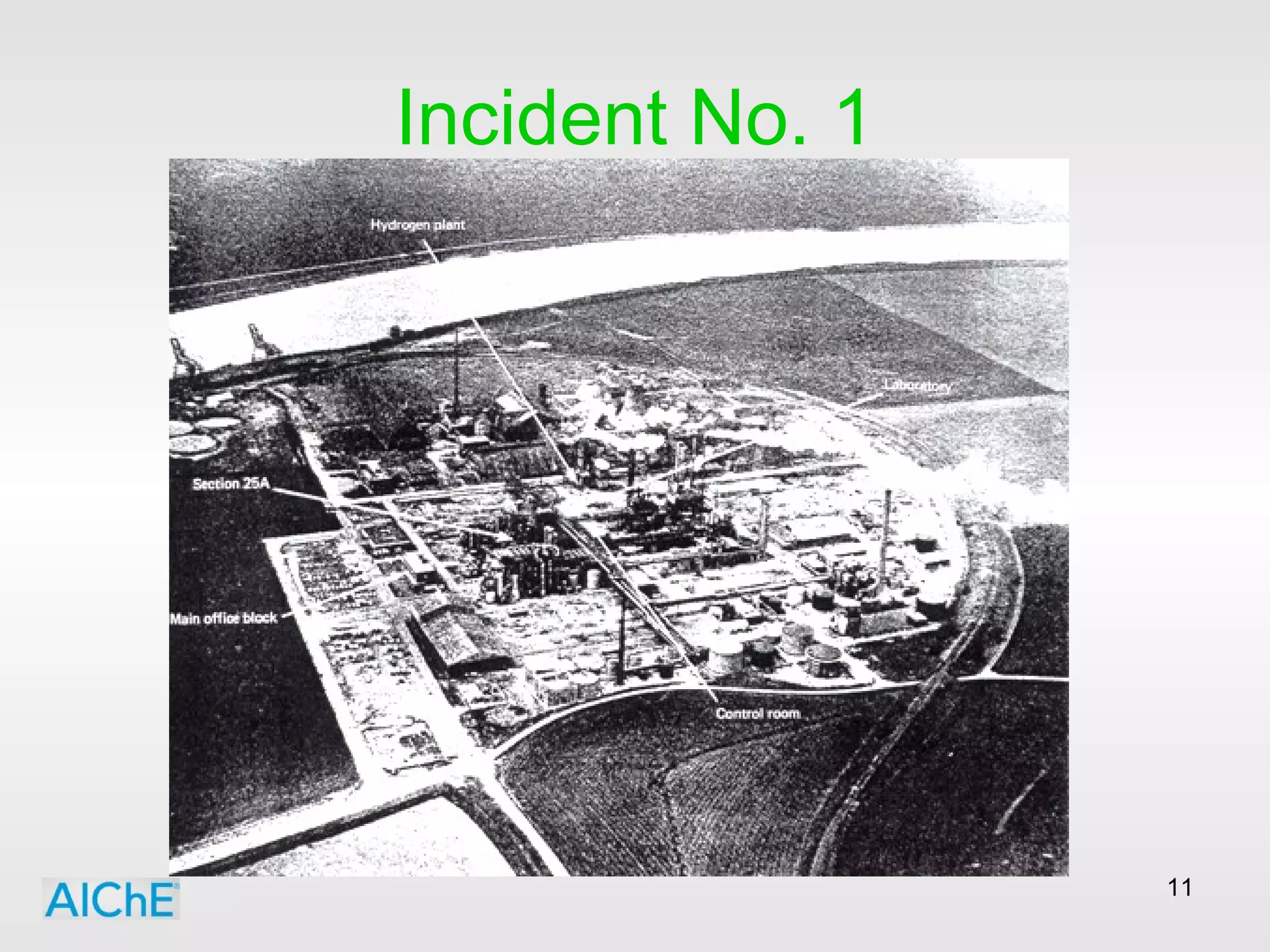

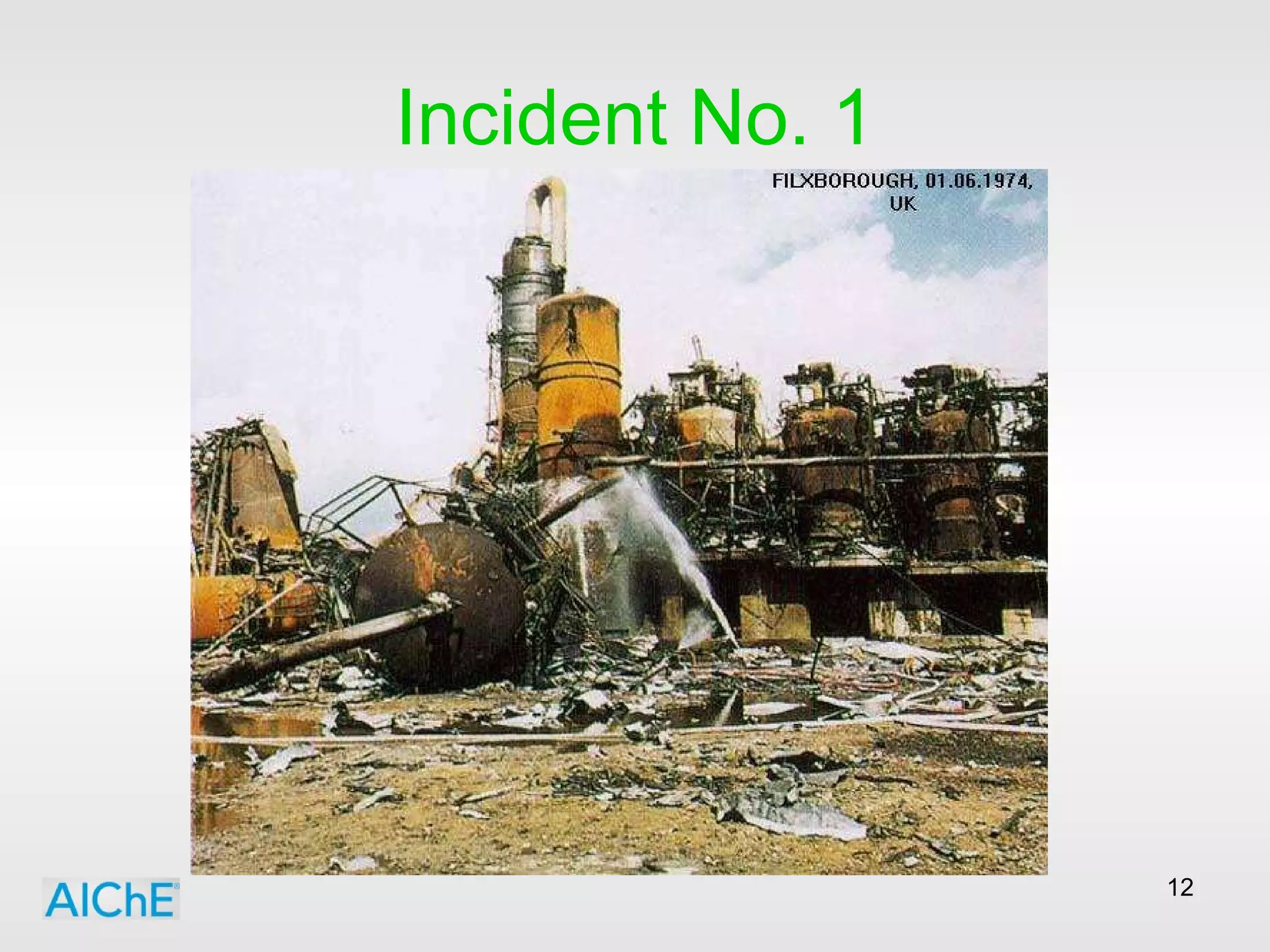

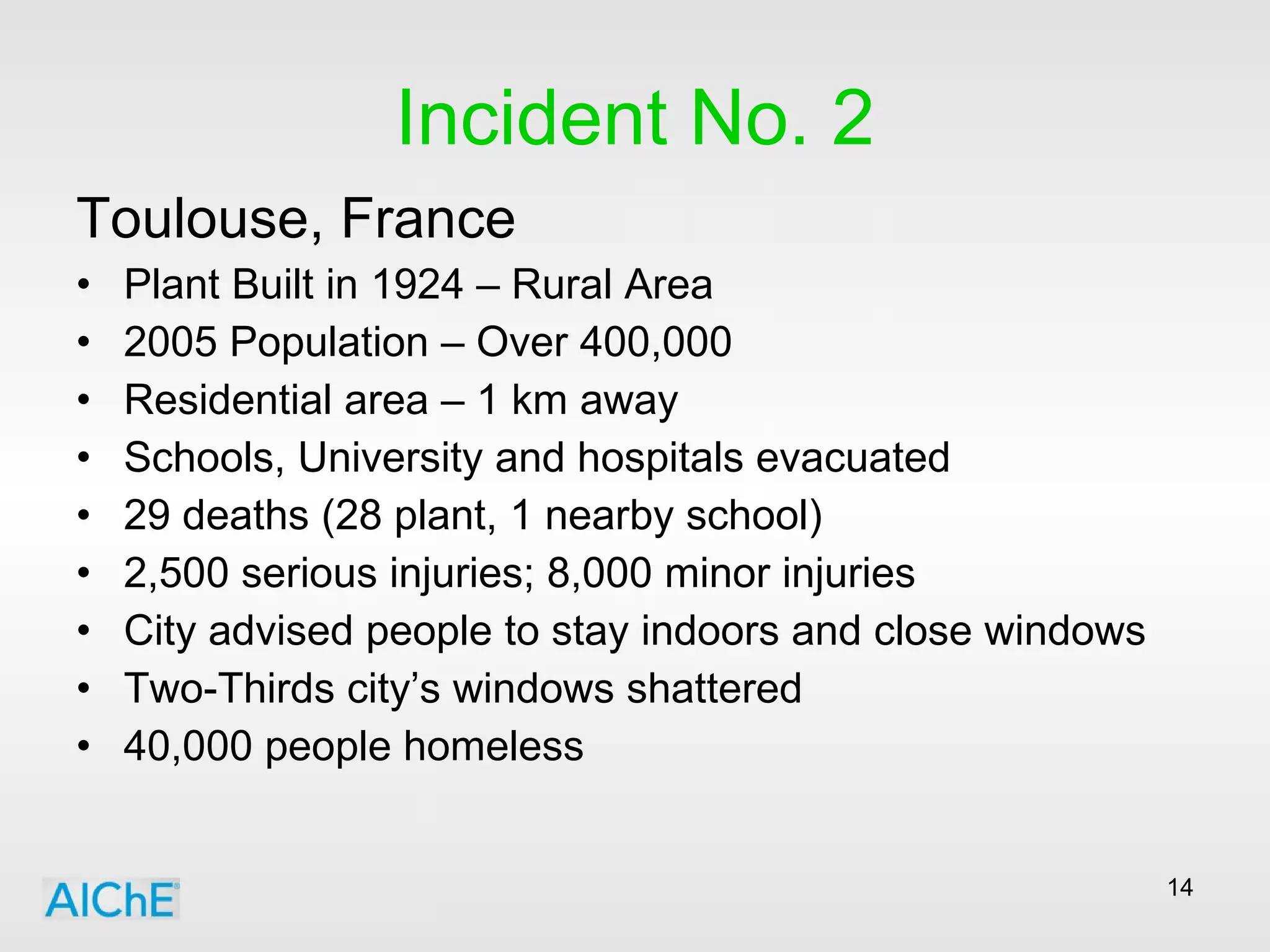

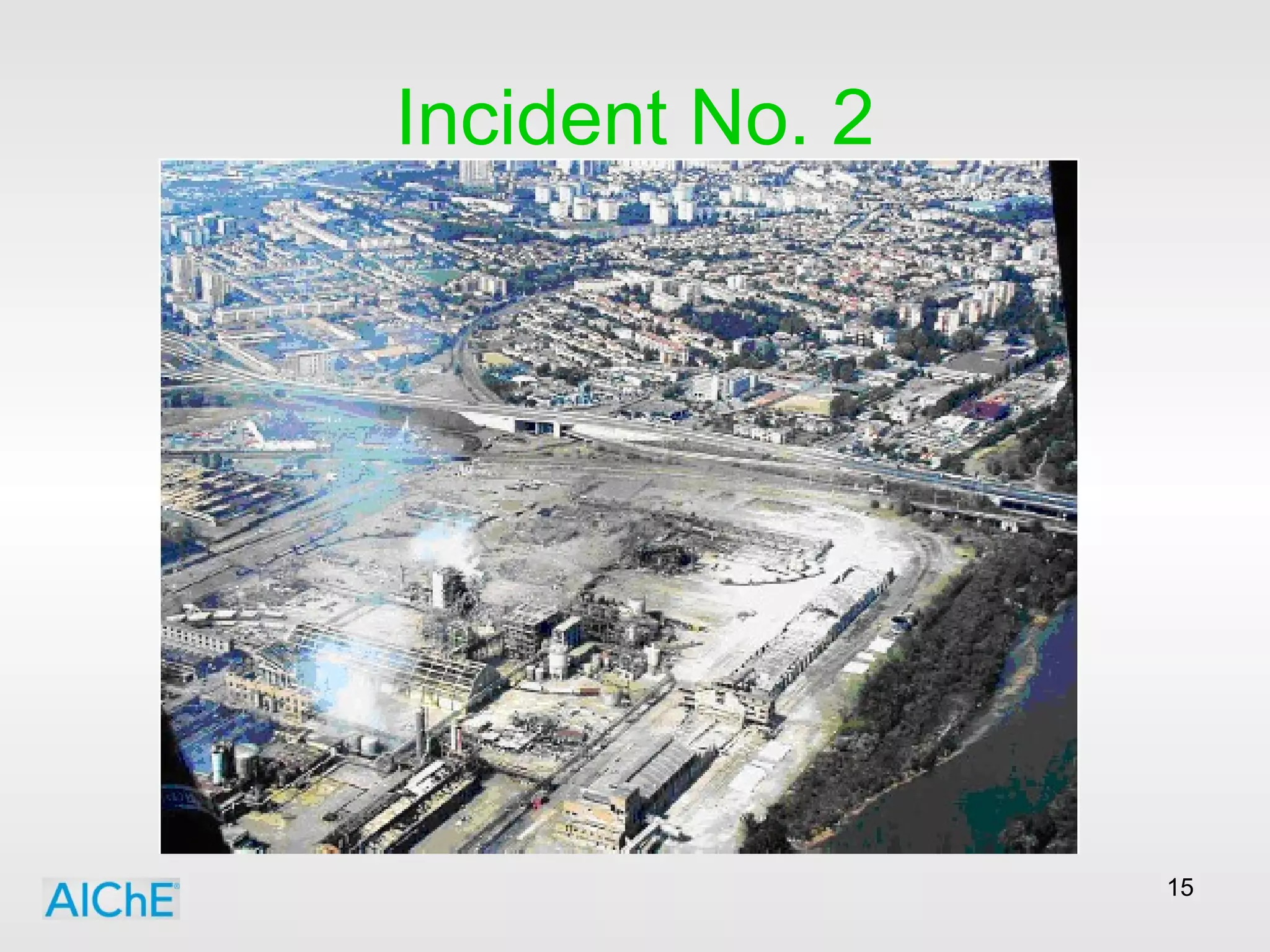

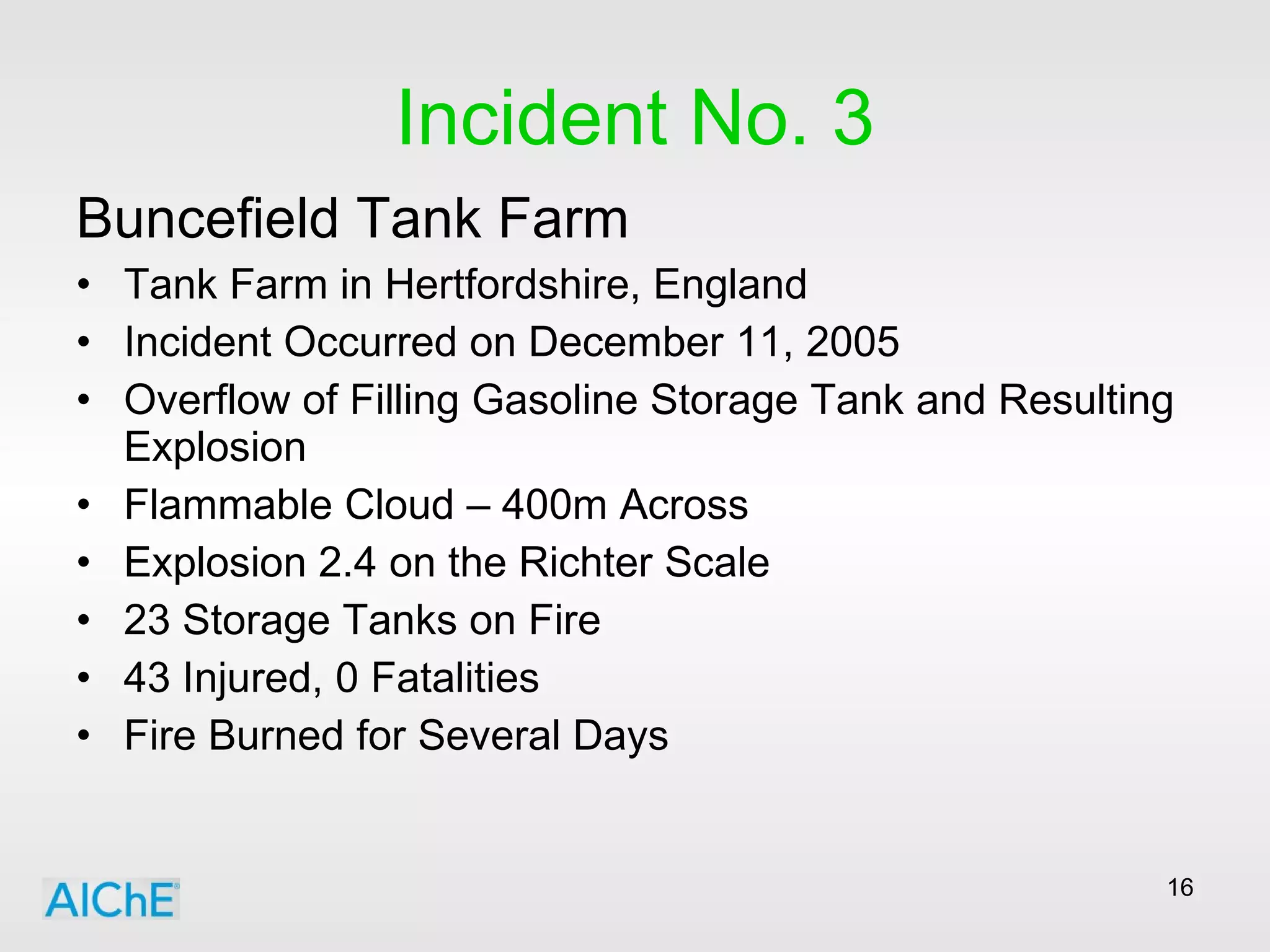

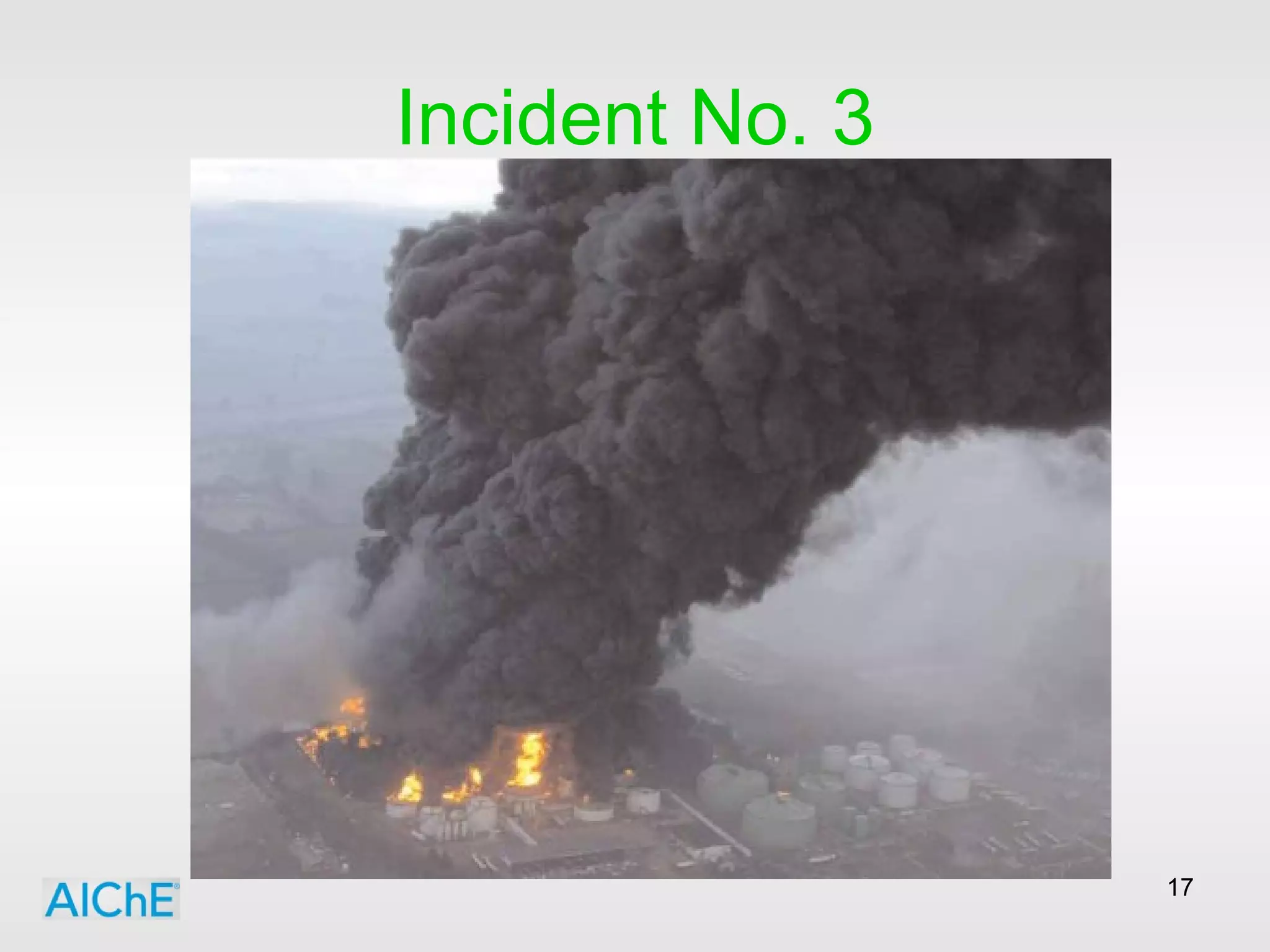

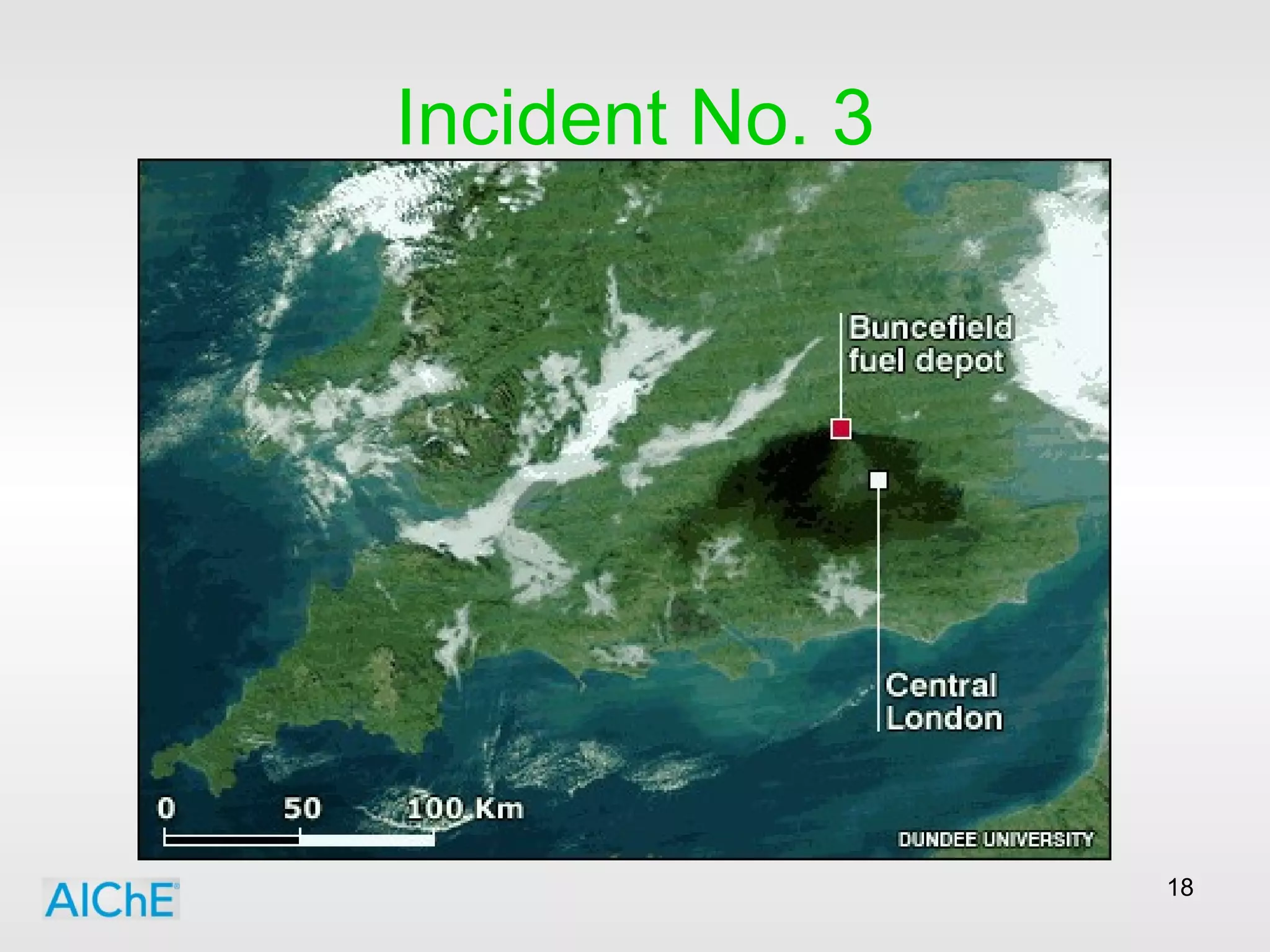

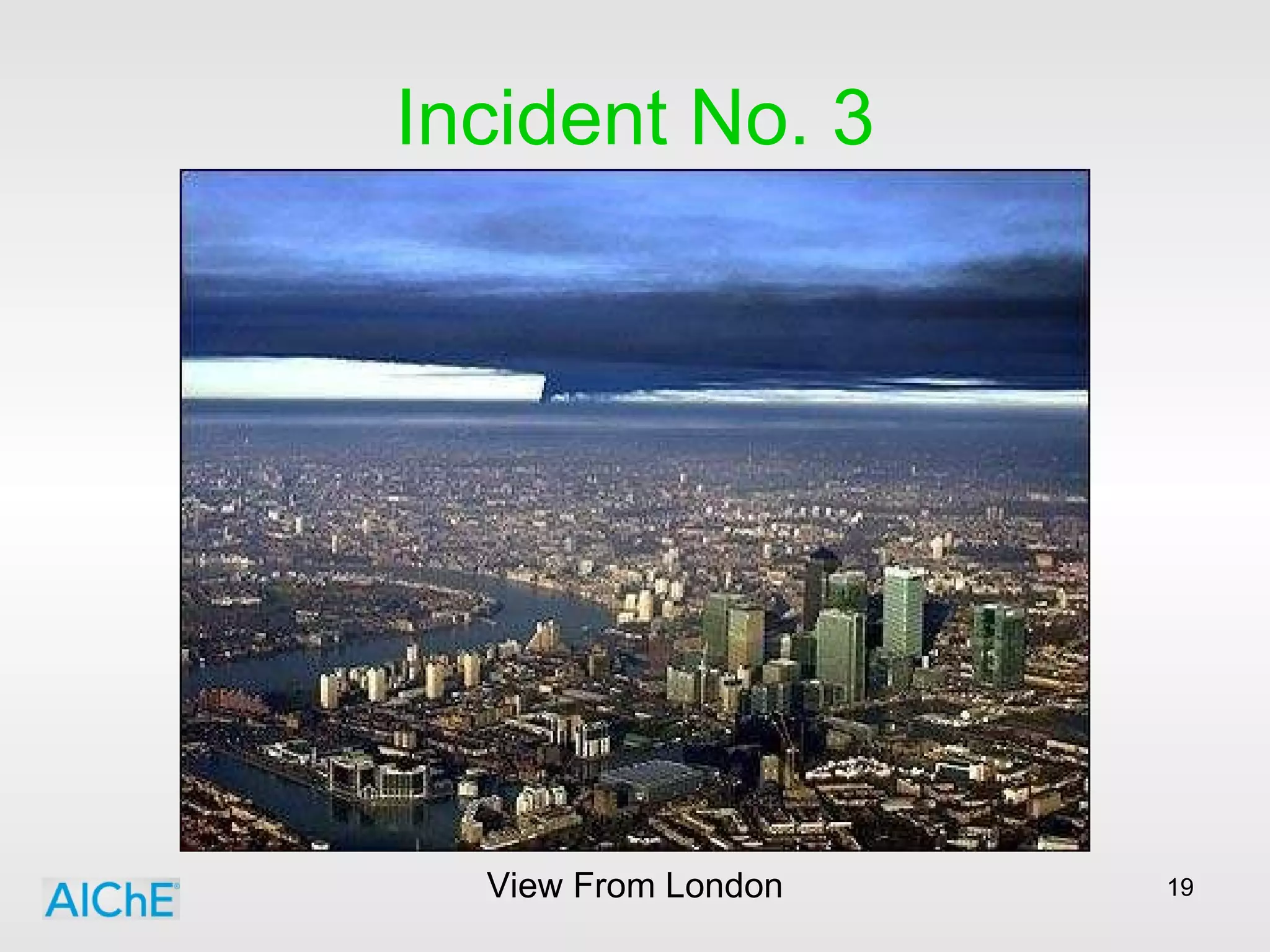

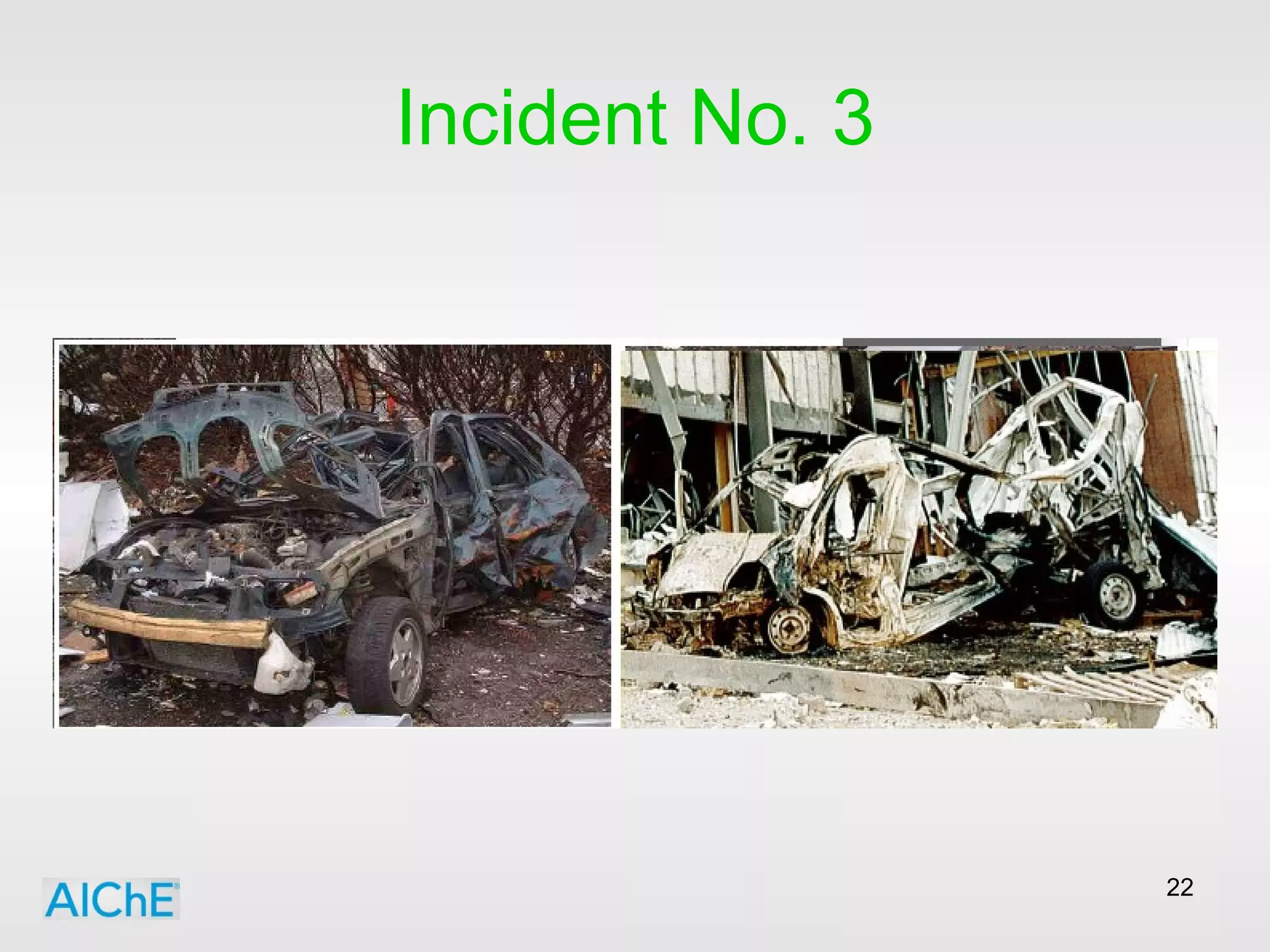

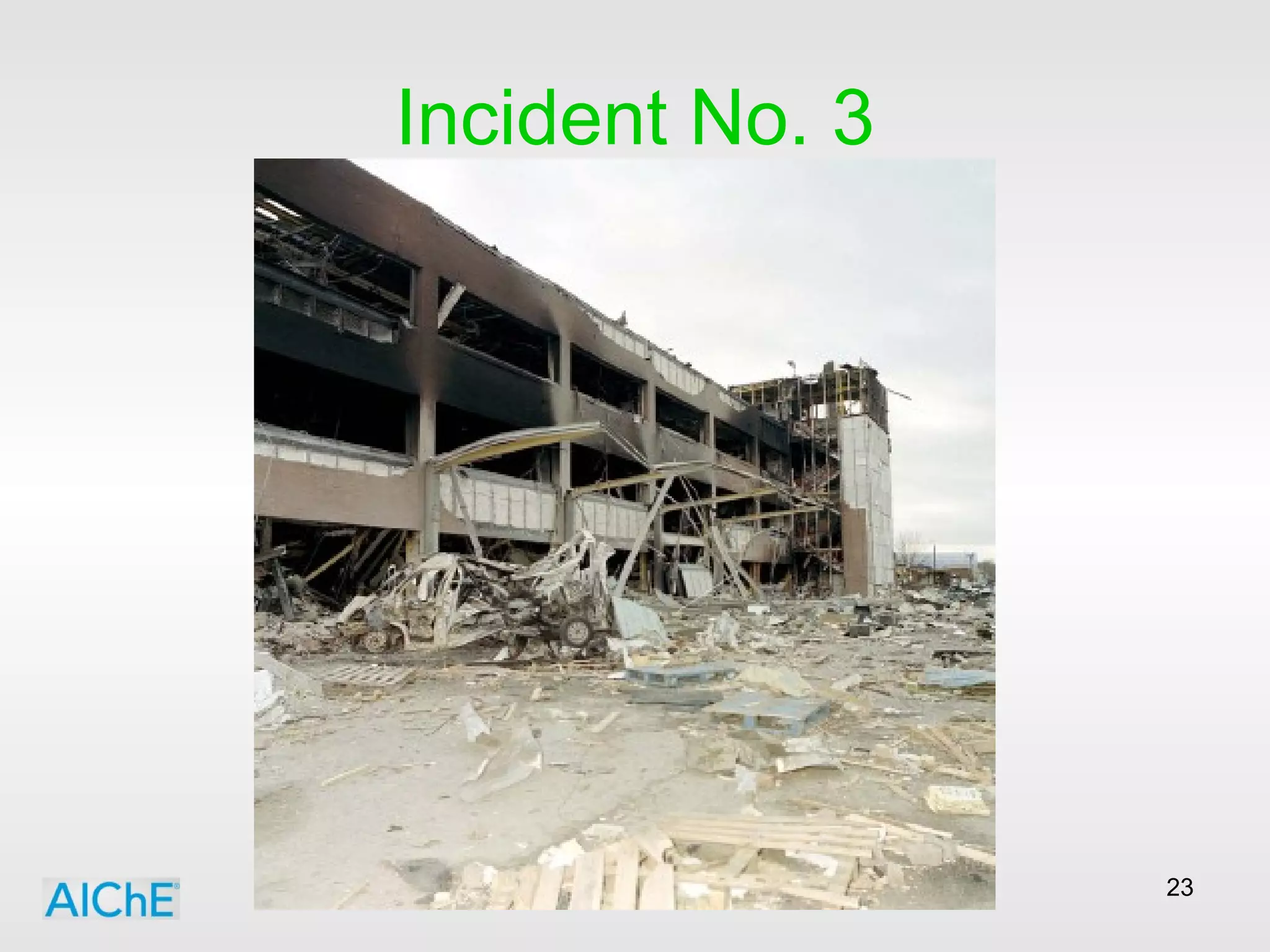

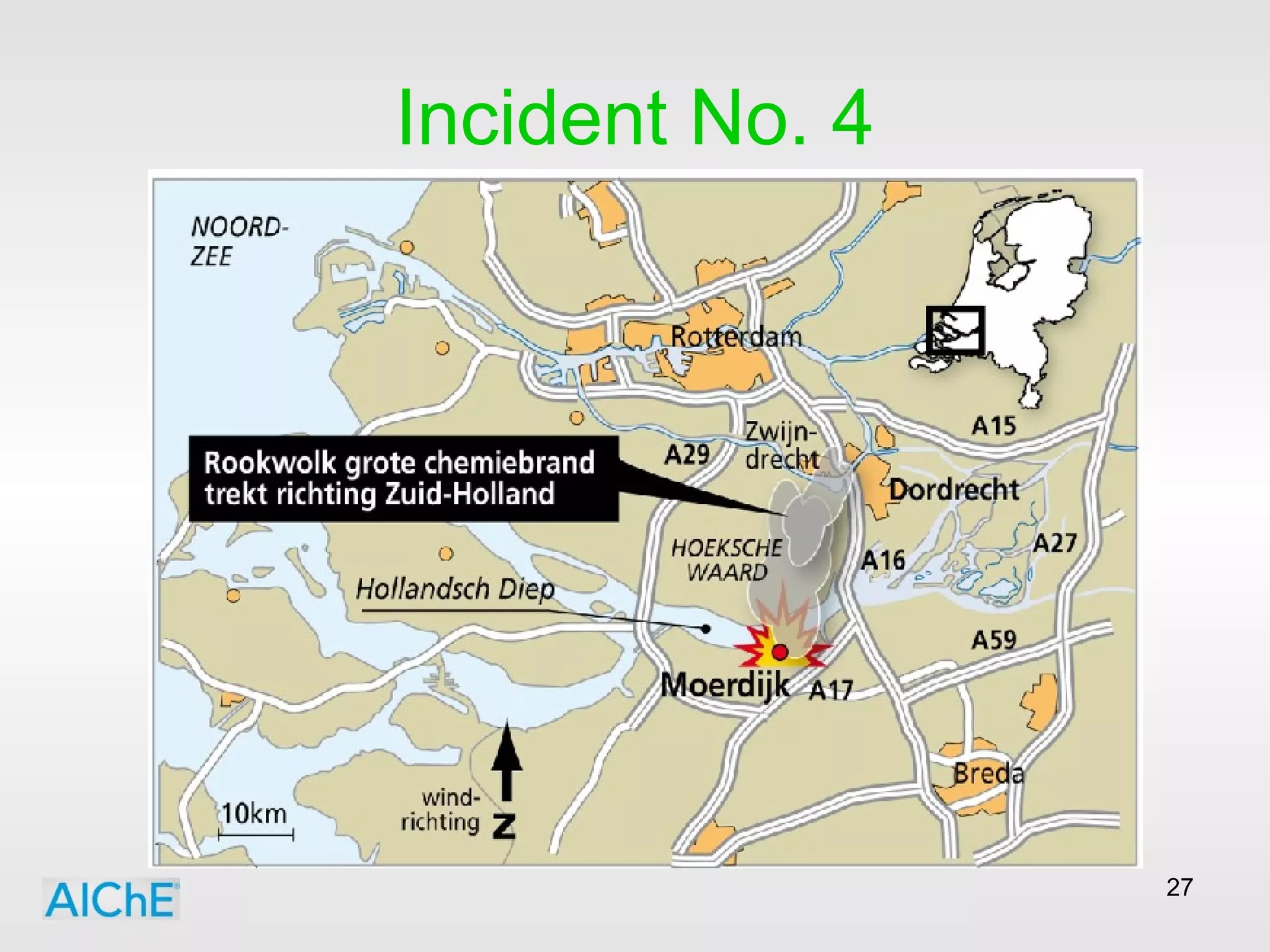

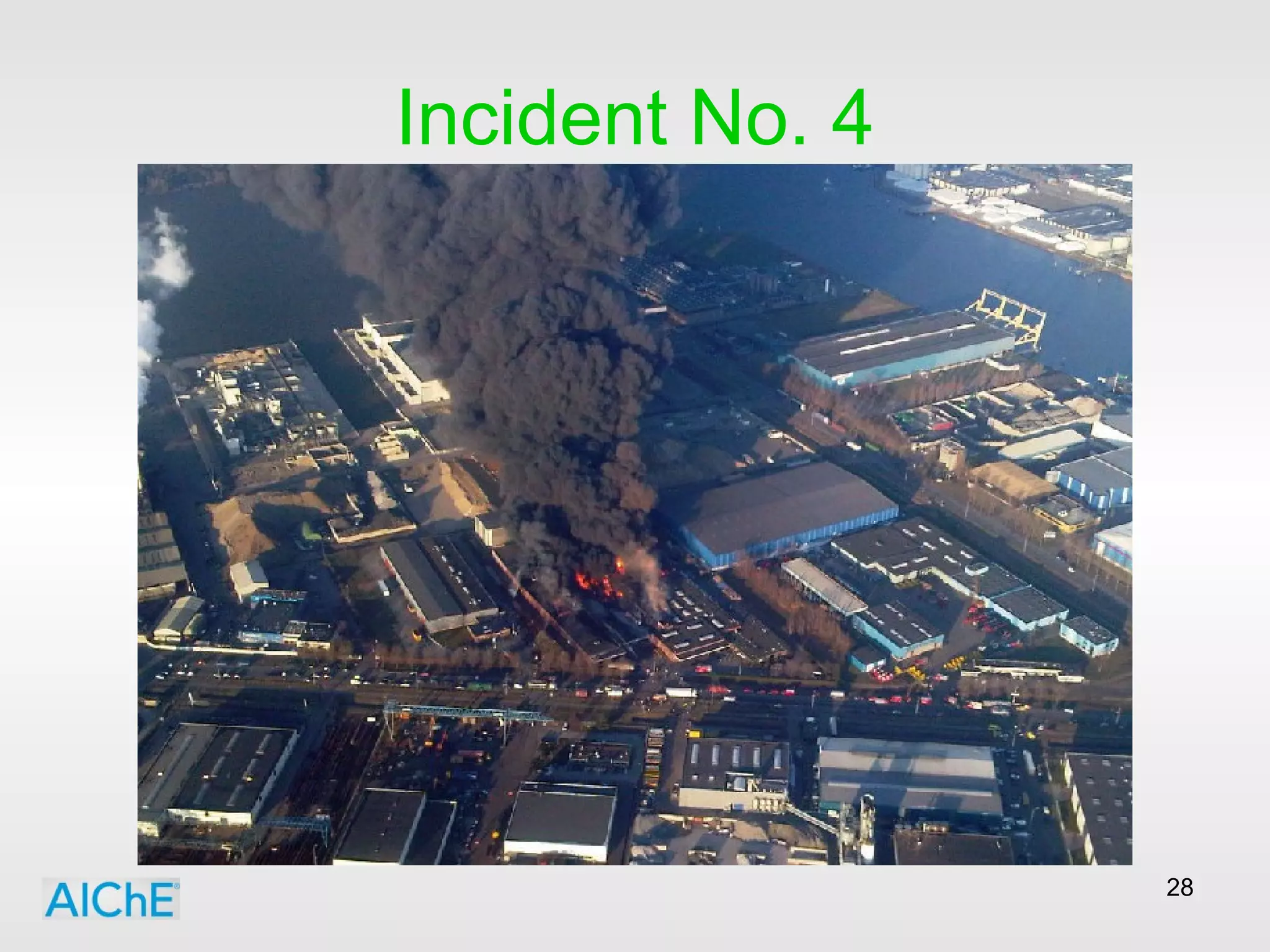

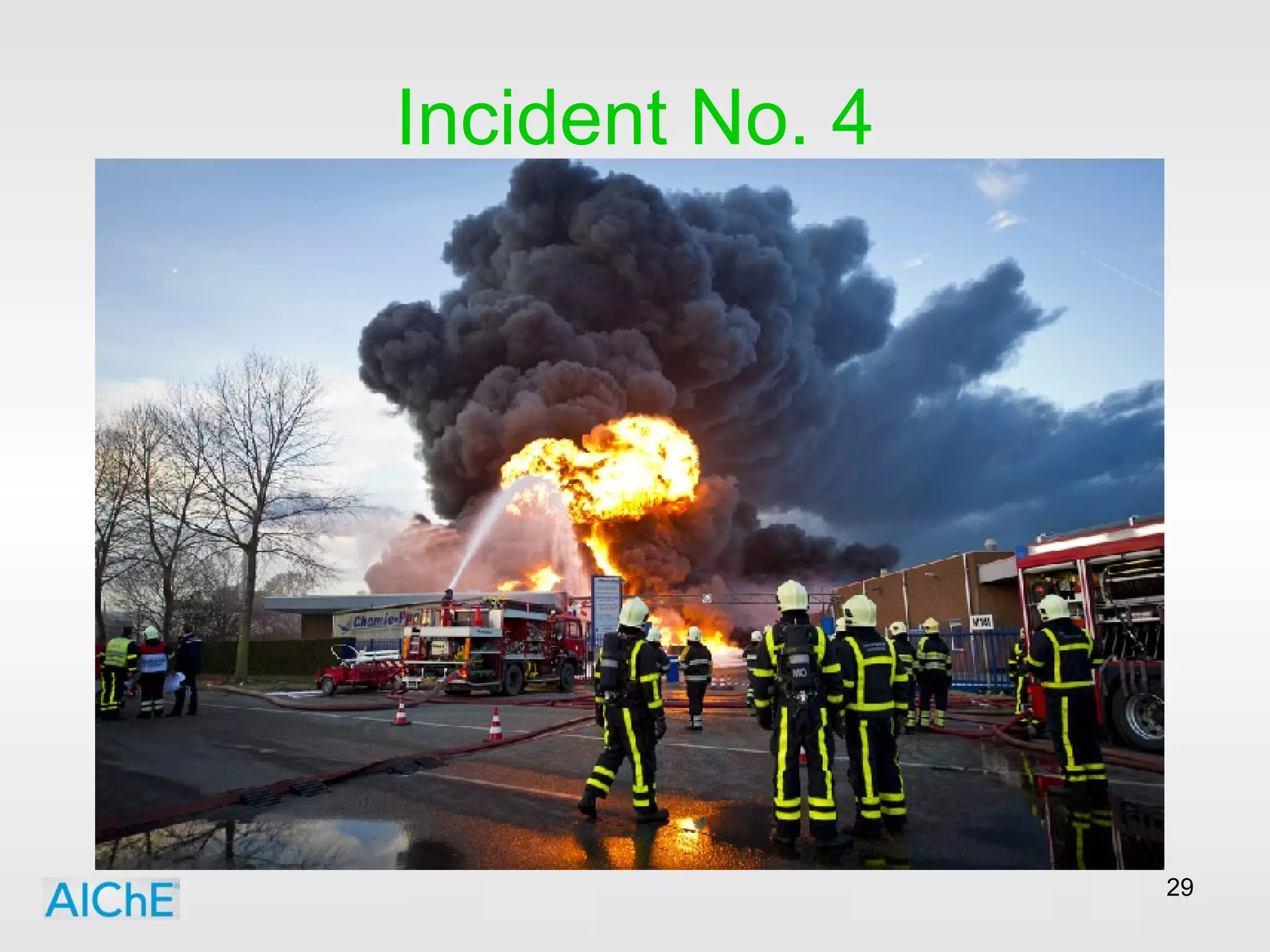

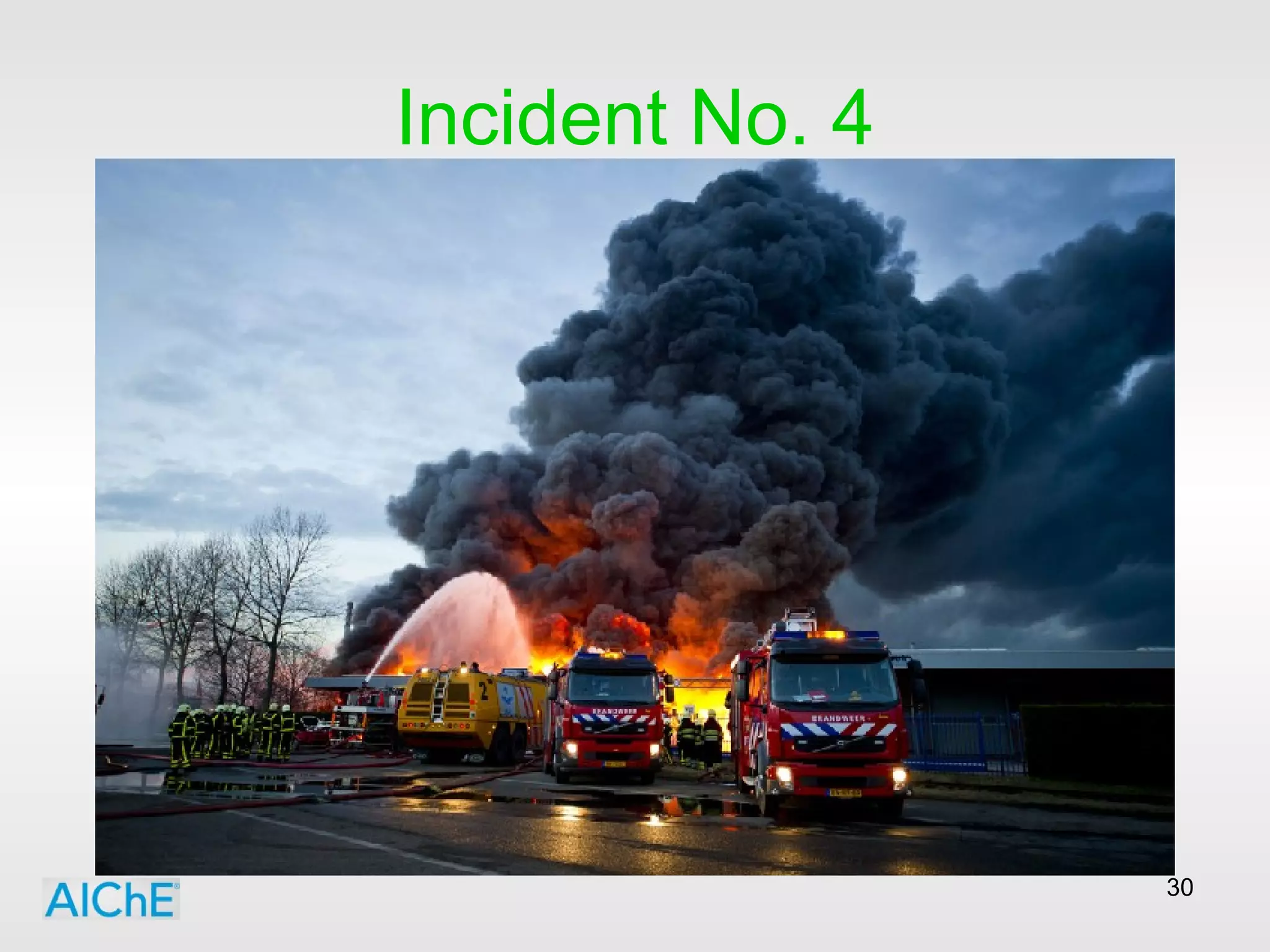

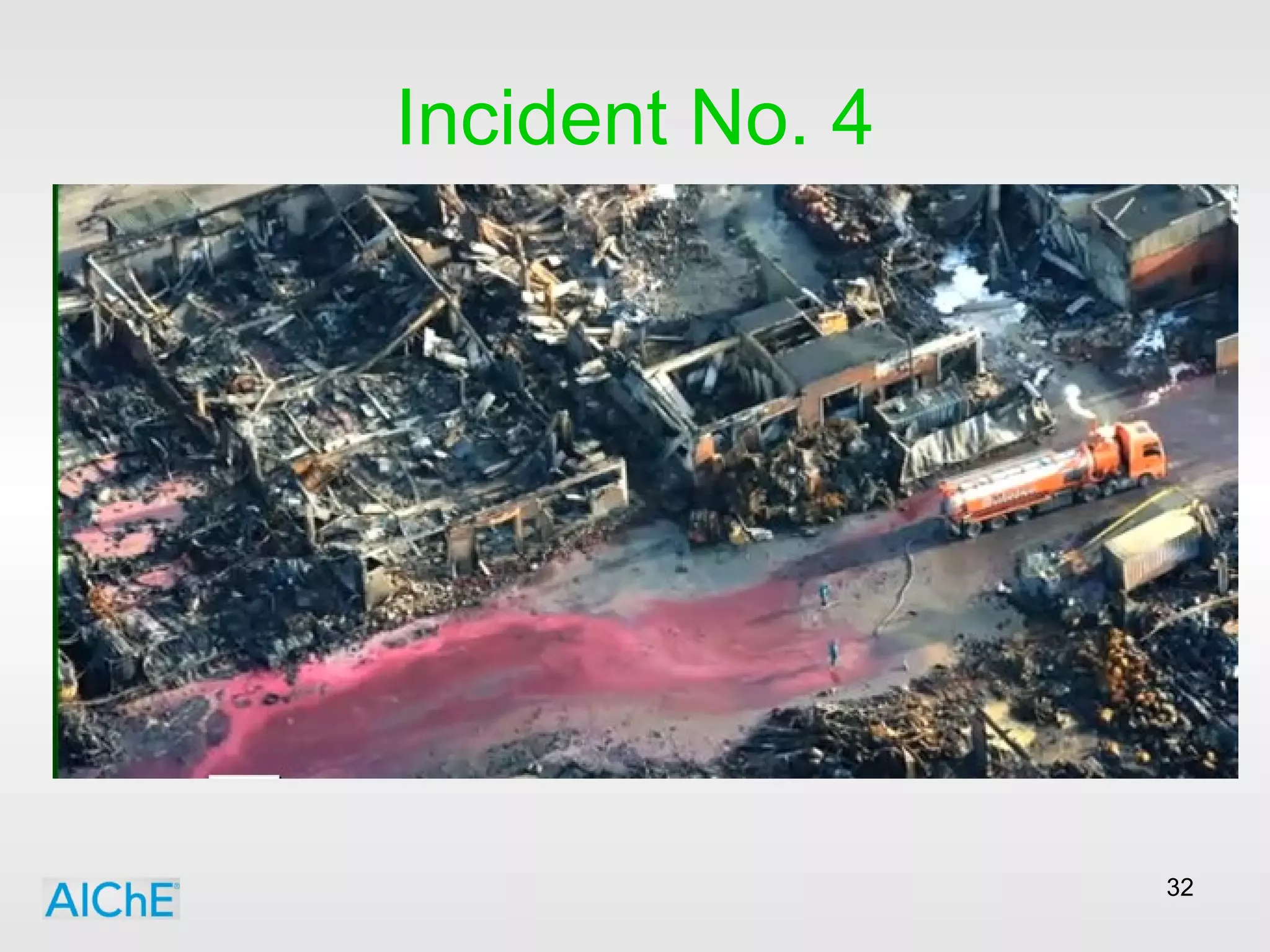

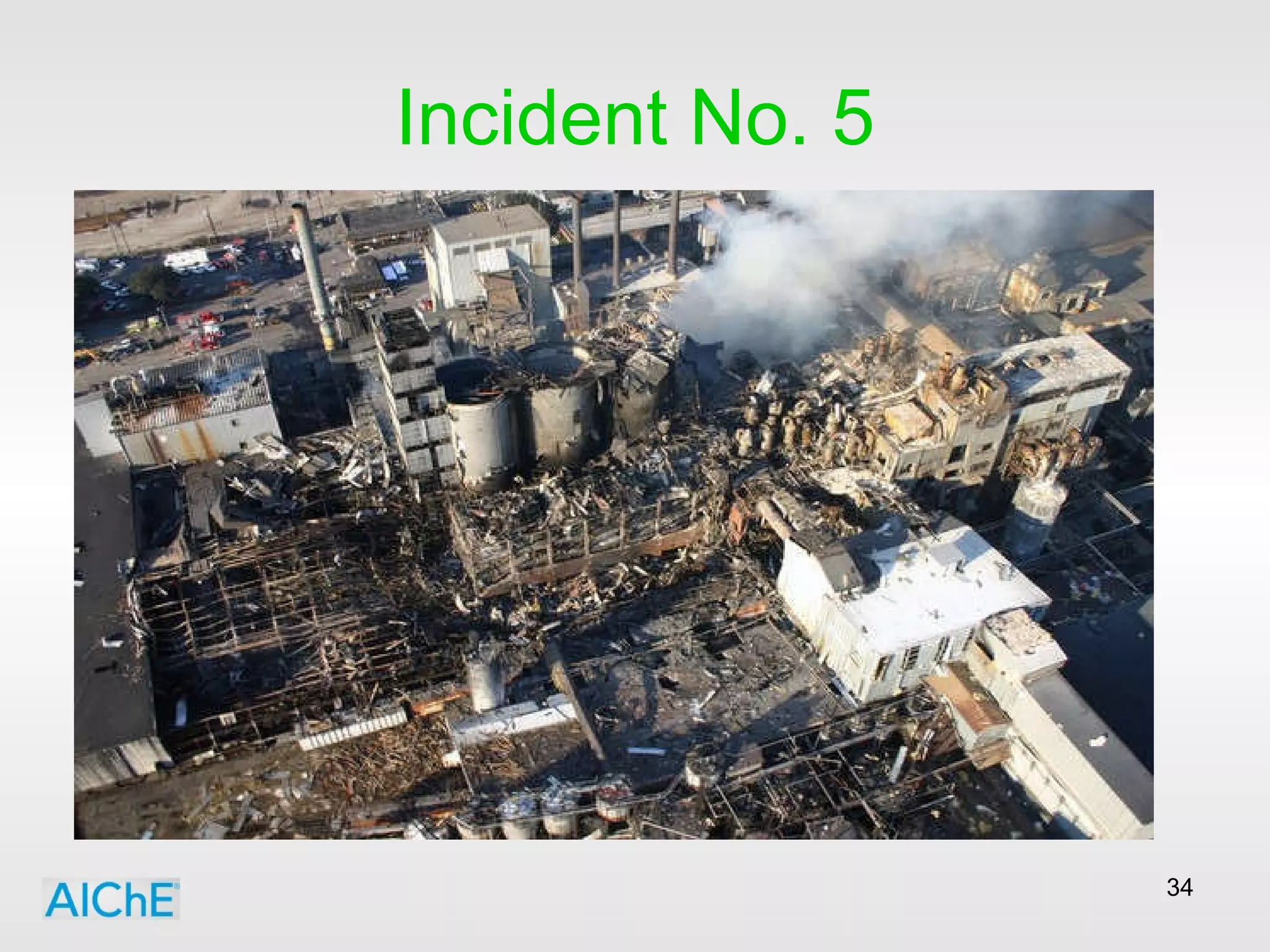

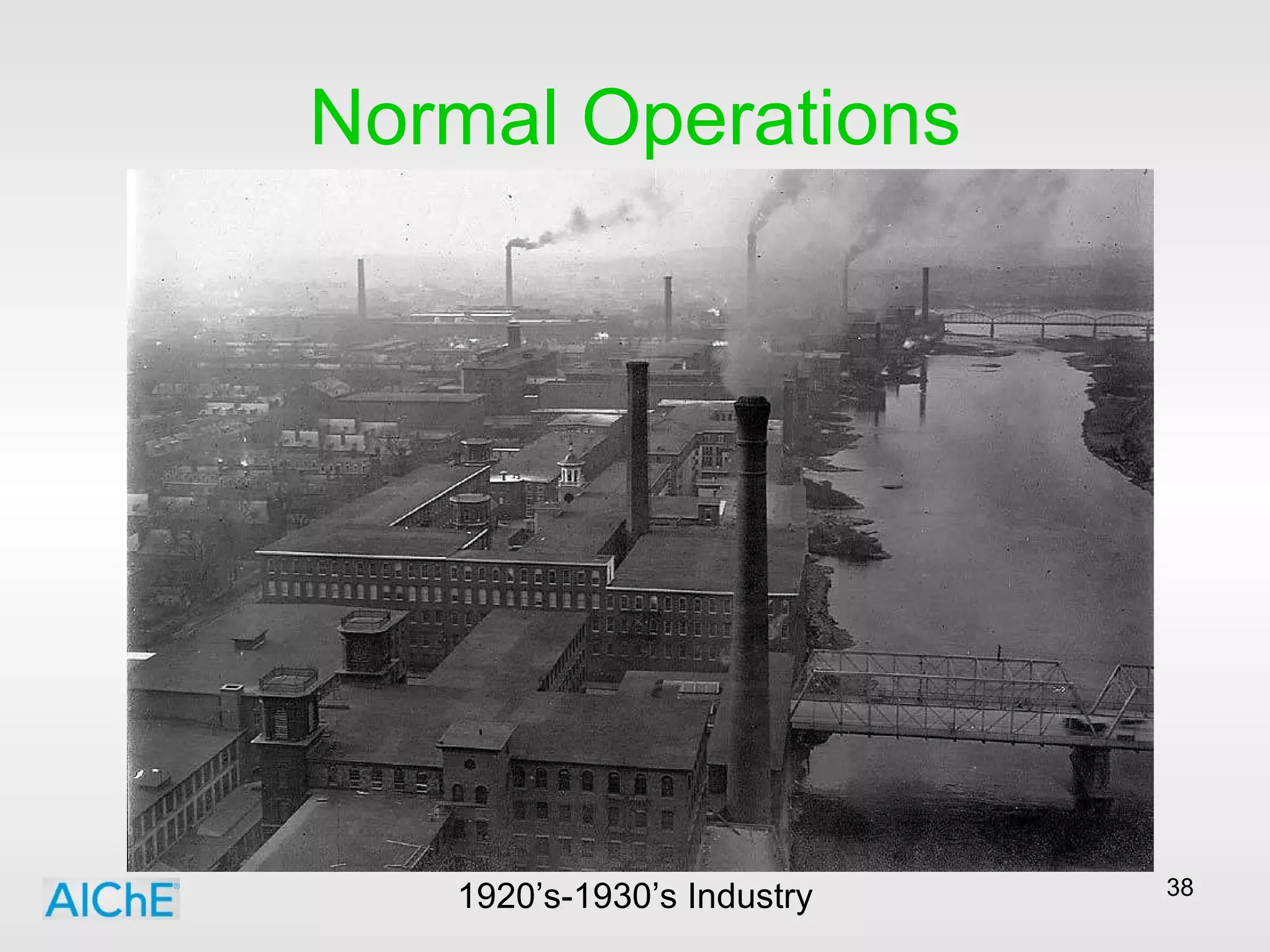

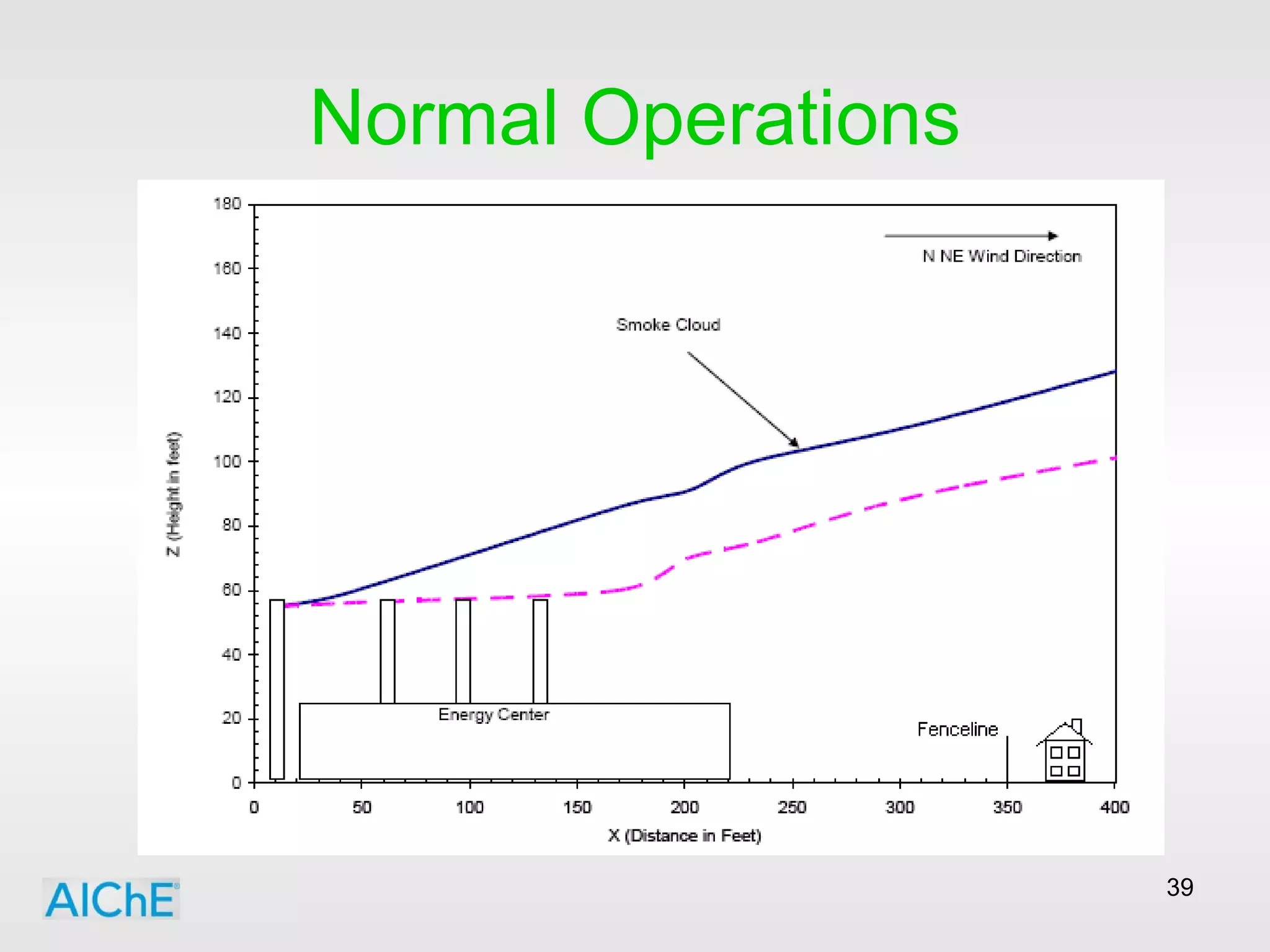

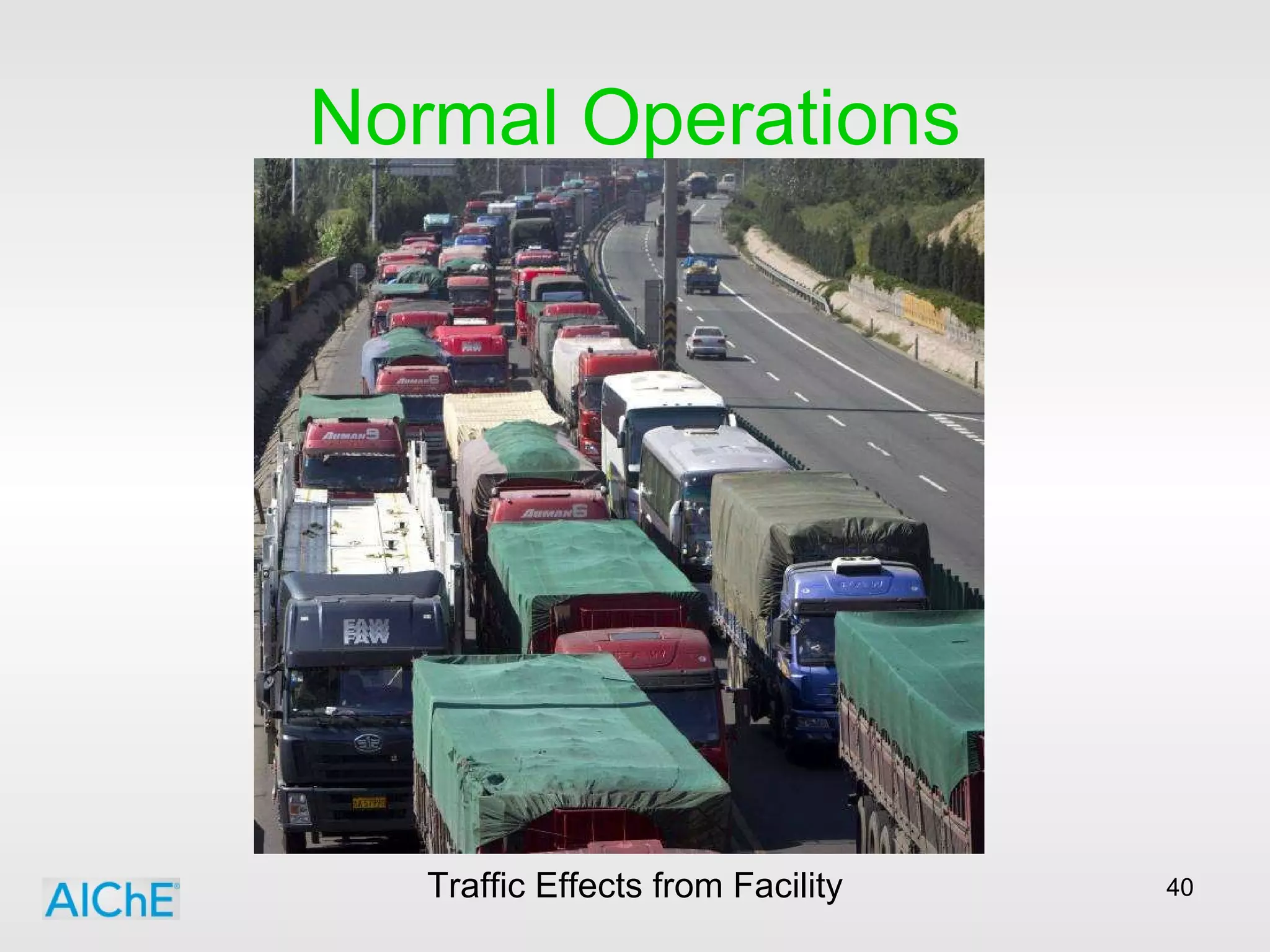

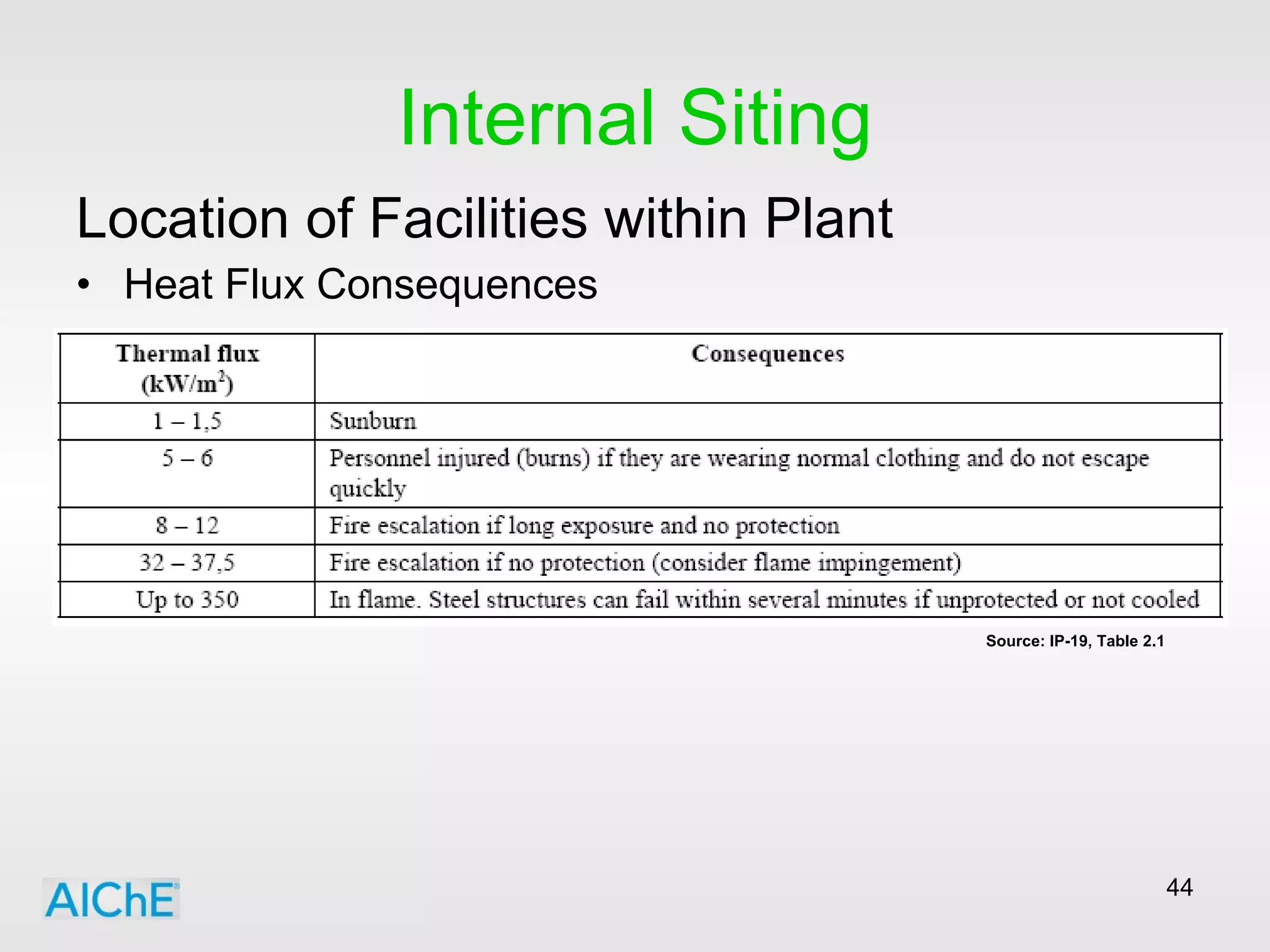

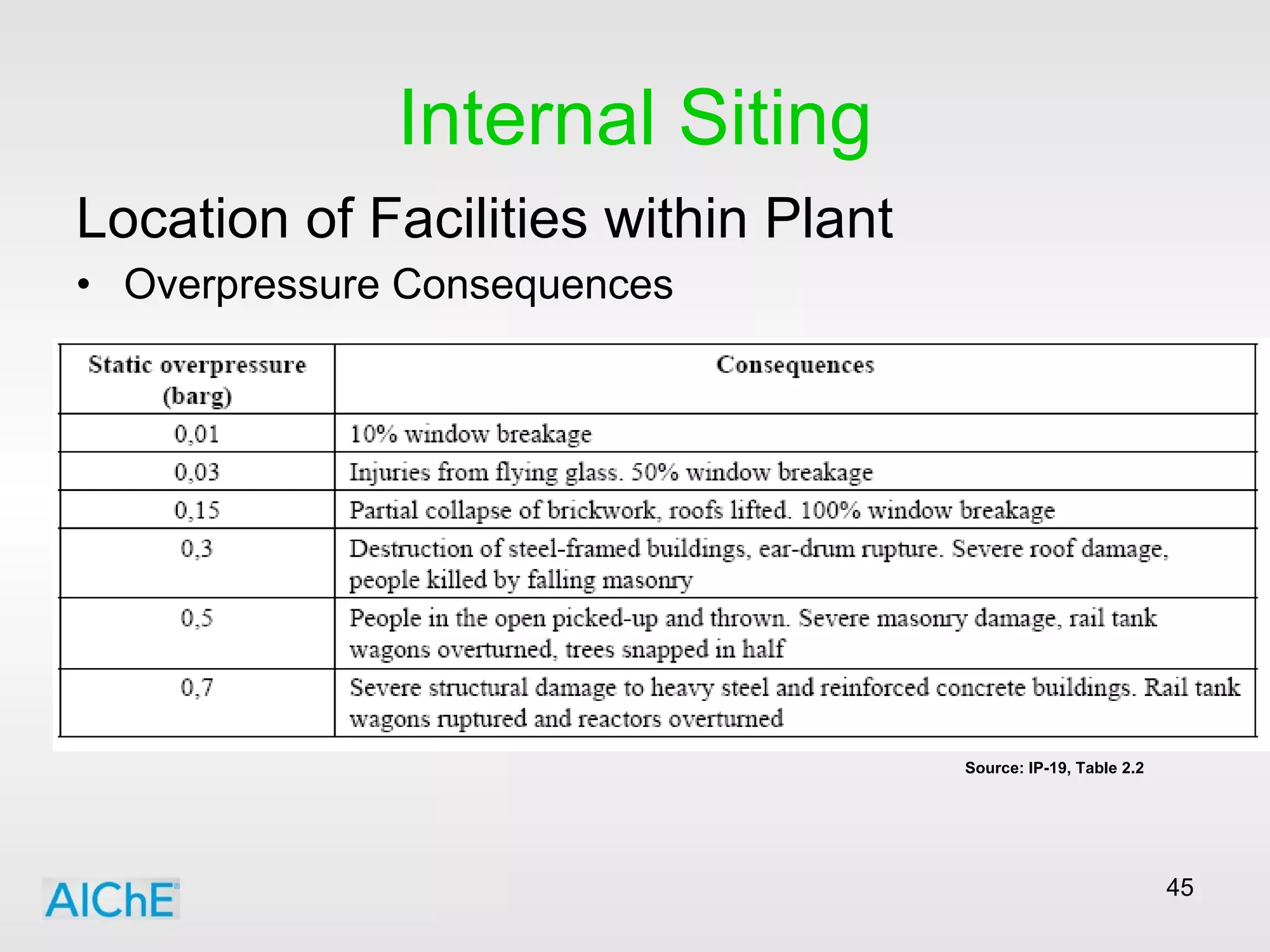

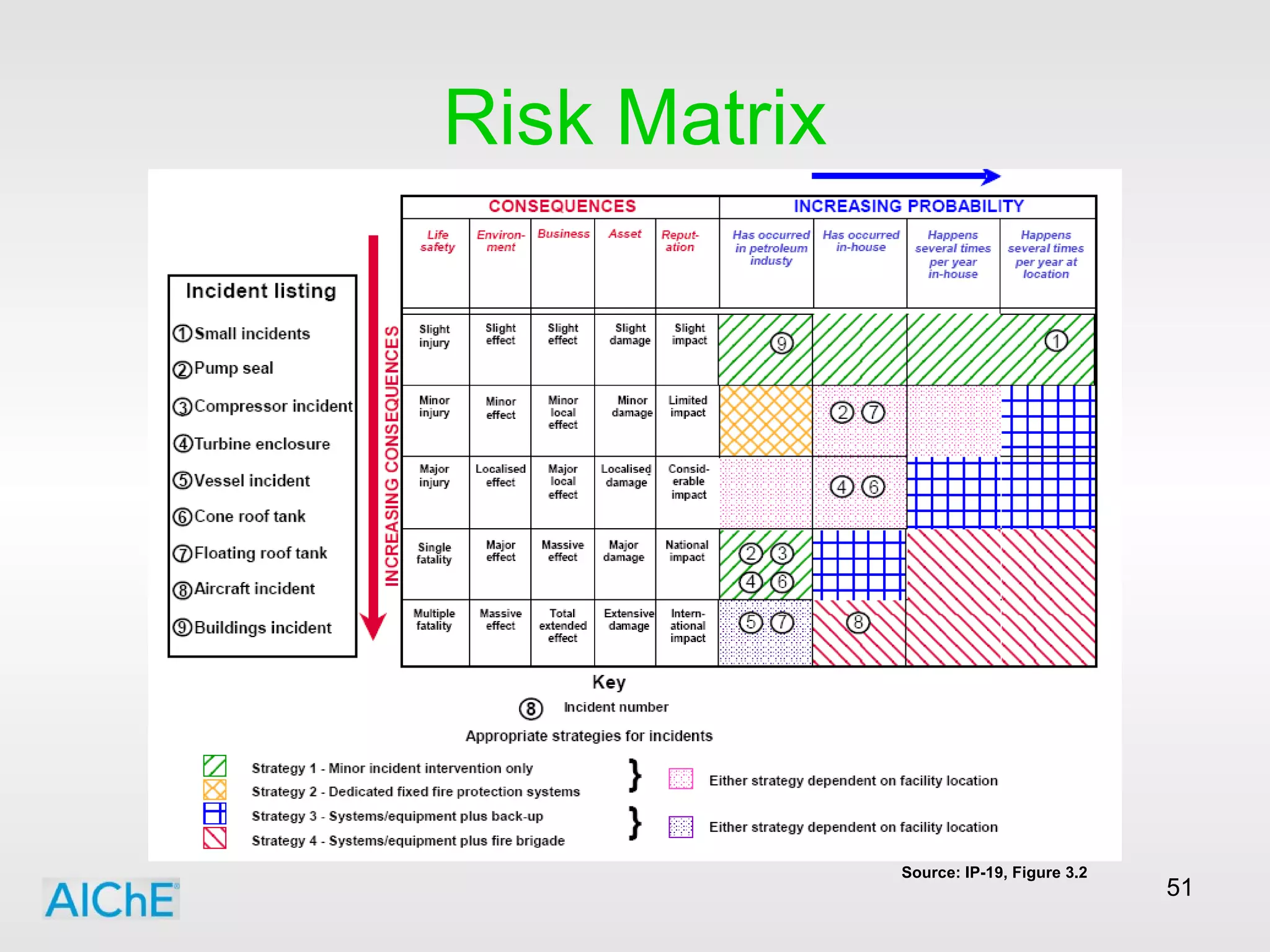

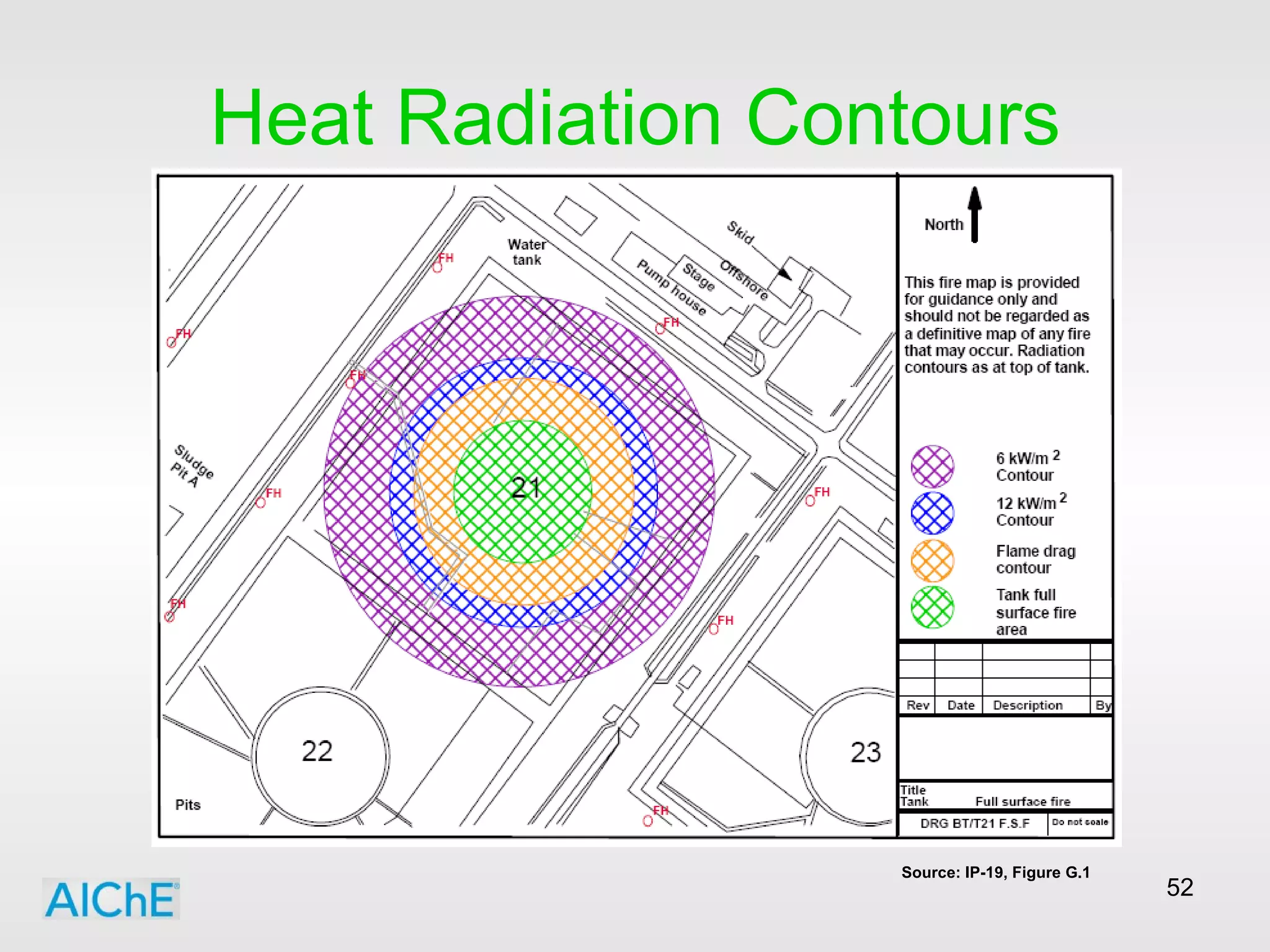

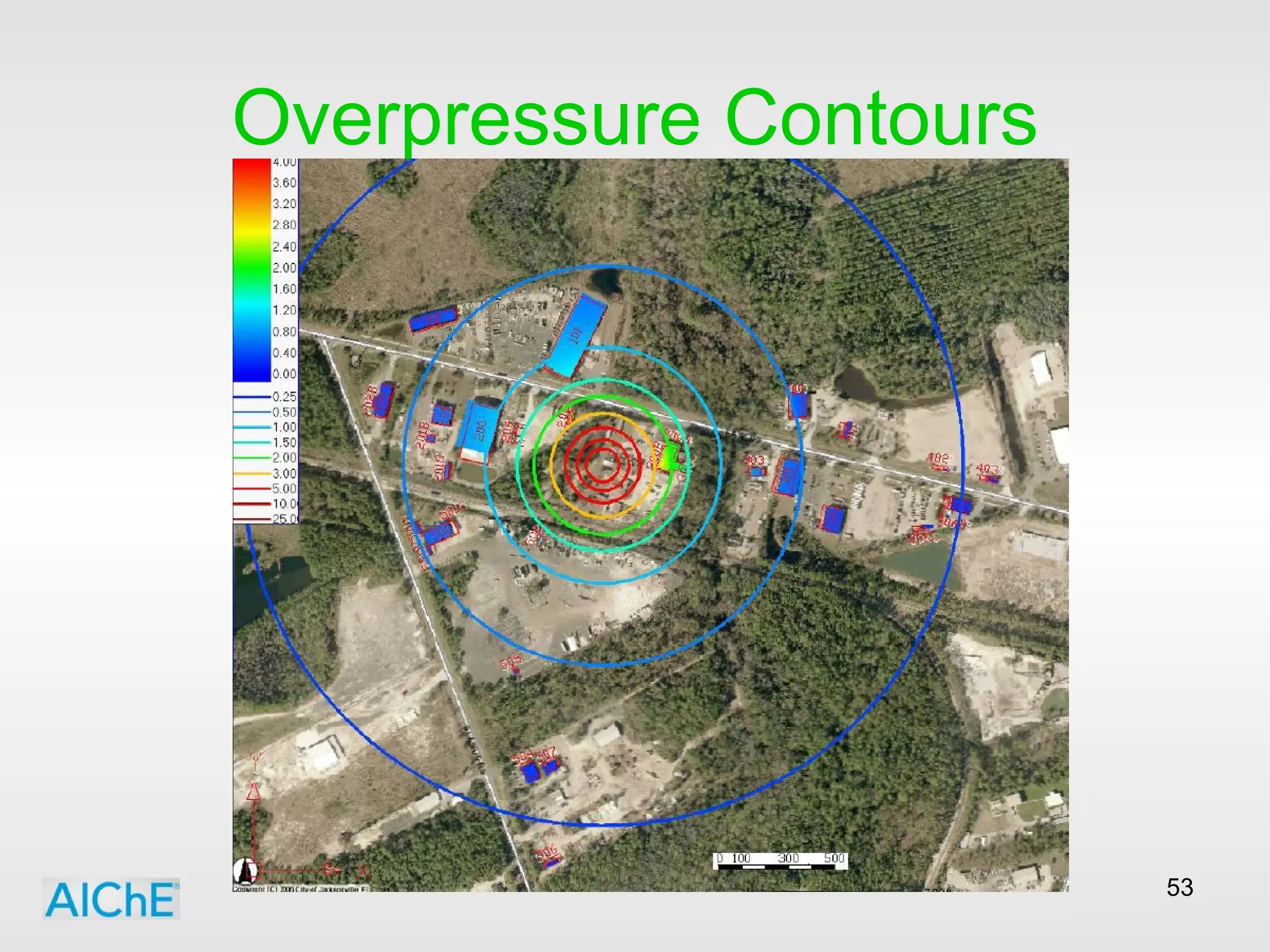

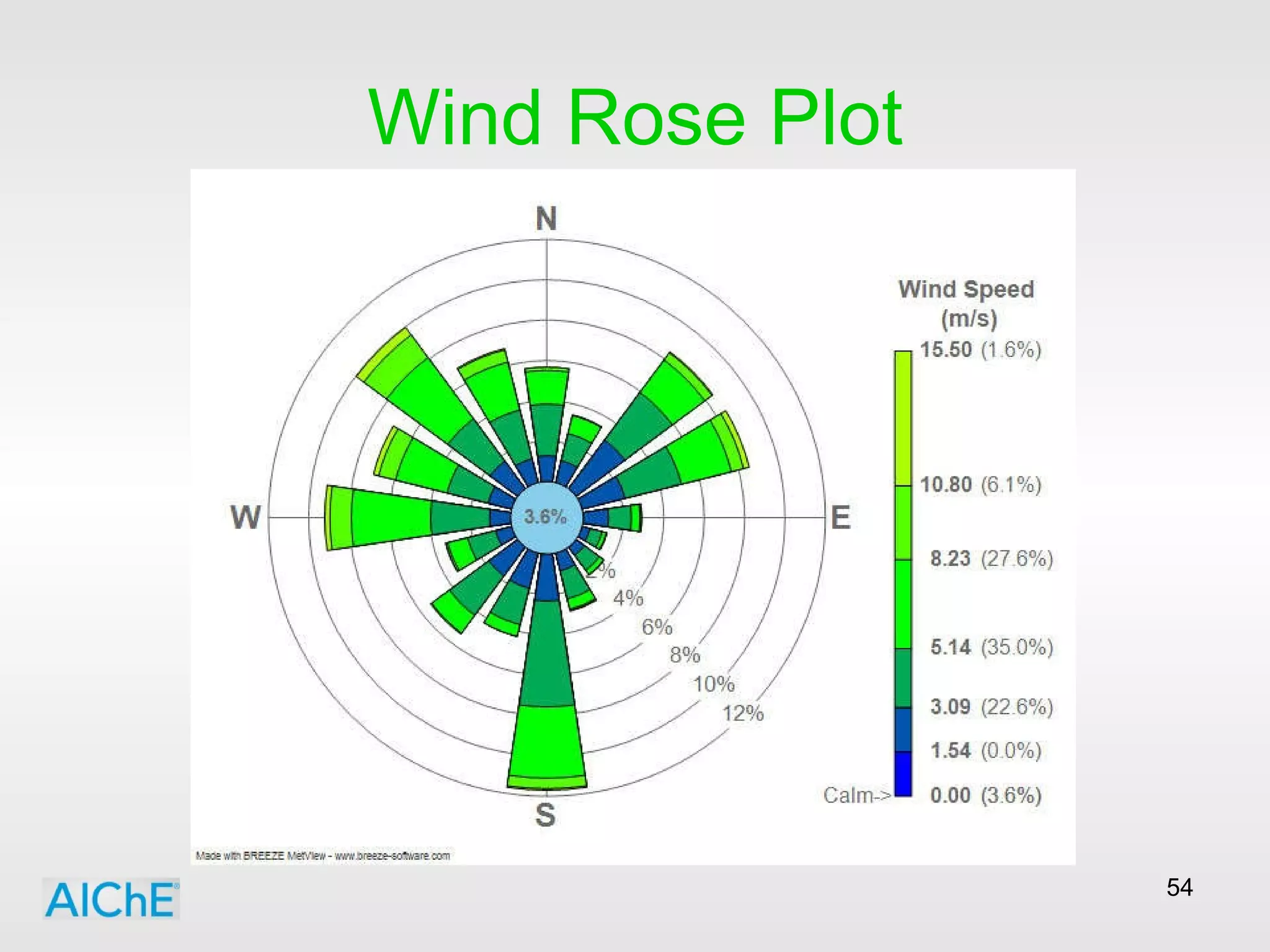

The document discusses the importance of facility planning and siting to prevent incidents and minimize risks. It outlines factors to consider for external and internal site location, including effects on the community, environment and operations. Examples of major chemical plant incidents are provided, demonstrating consequences of fires, explosions and toxic releases. The planning process involves risk assessments of hazards, controls to reduce risk, and following industry standards.