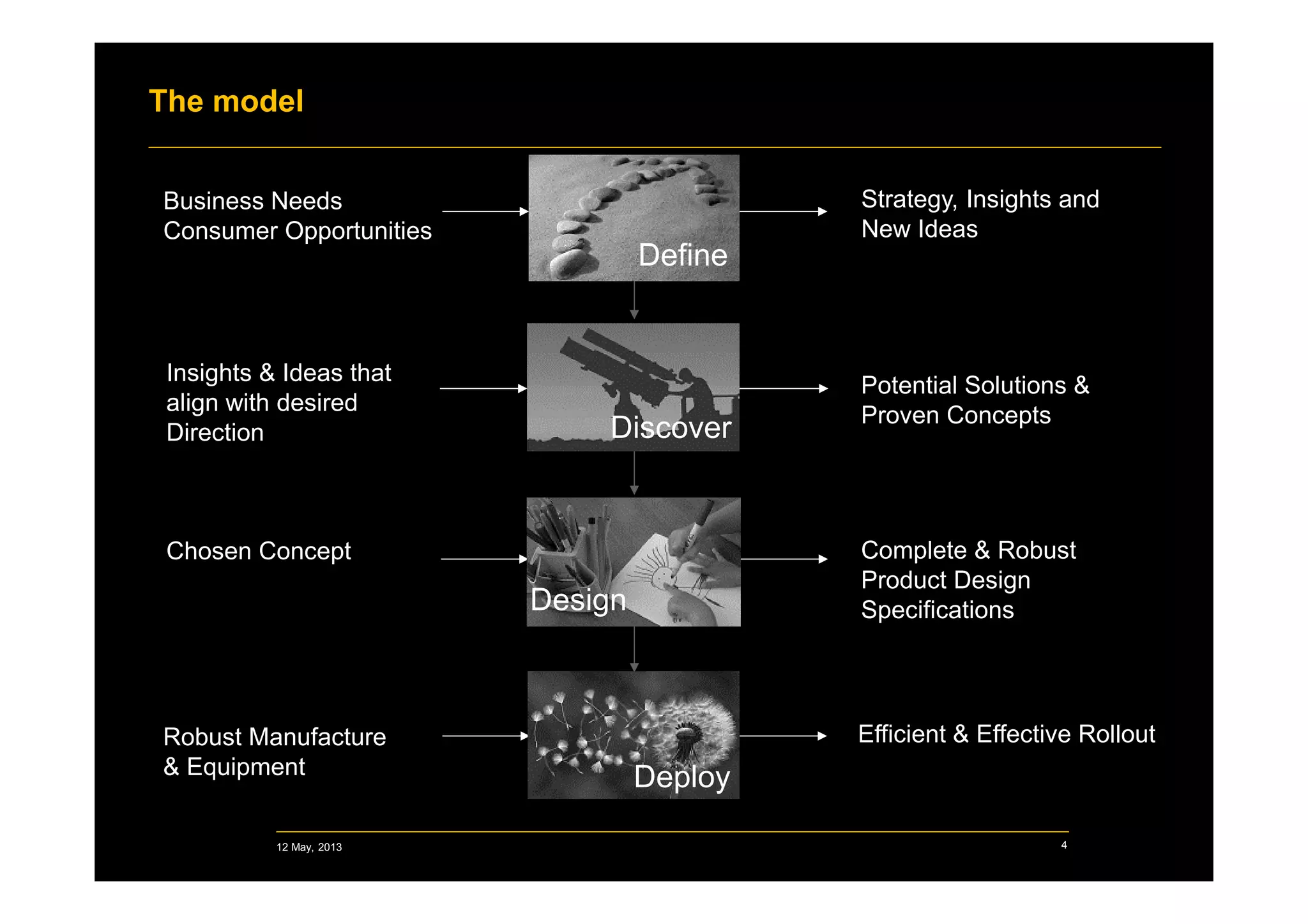

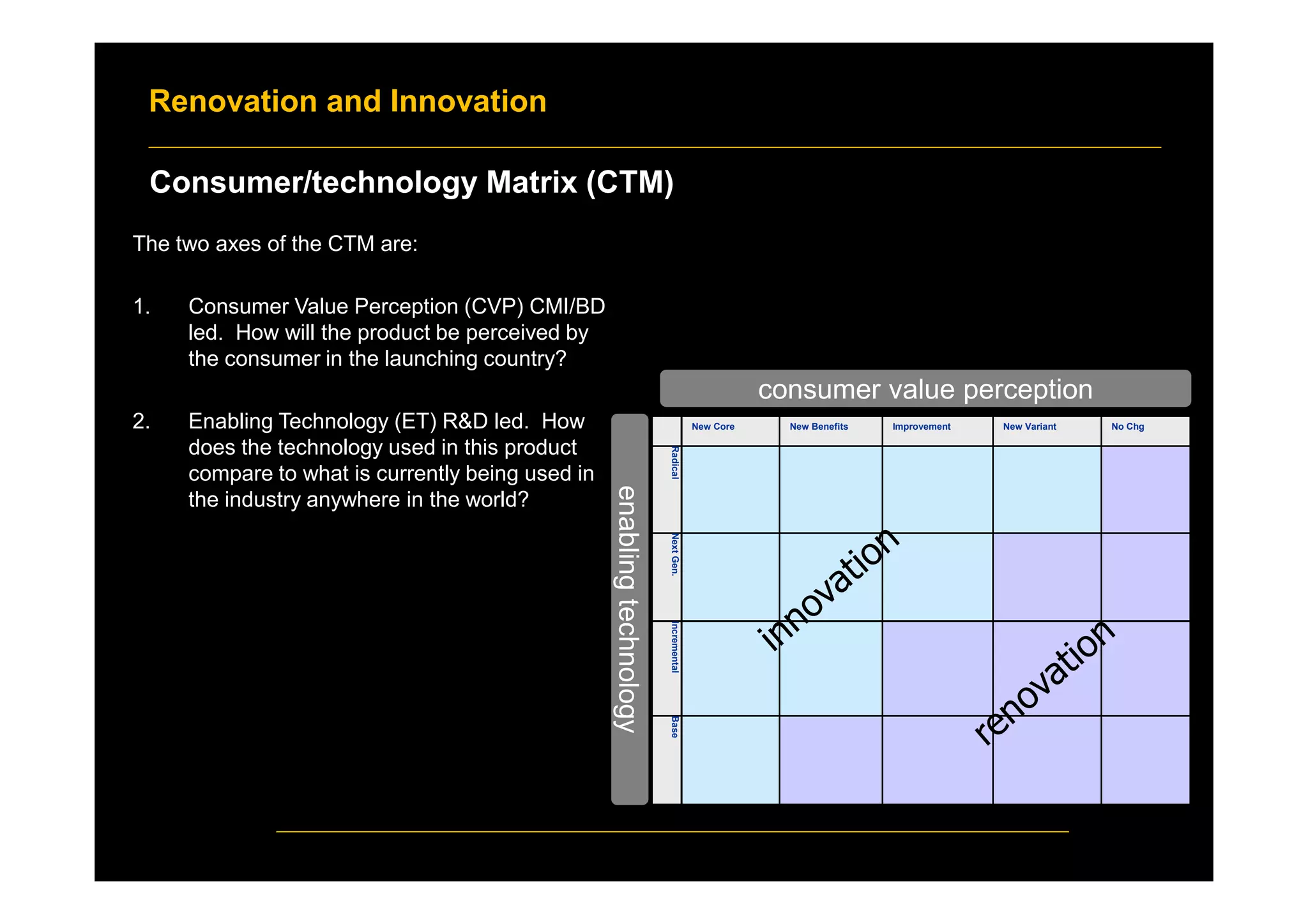

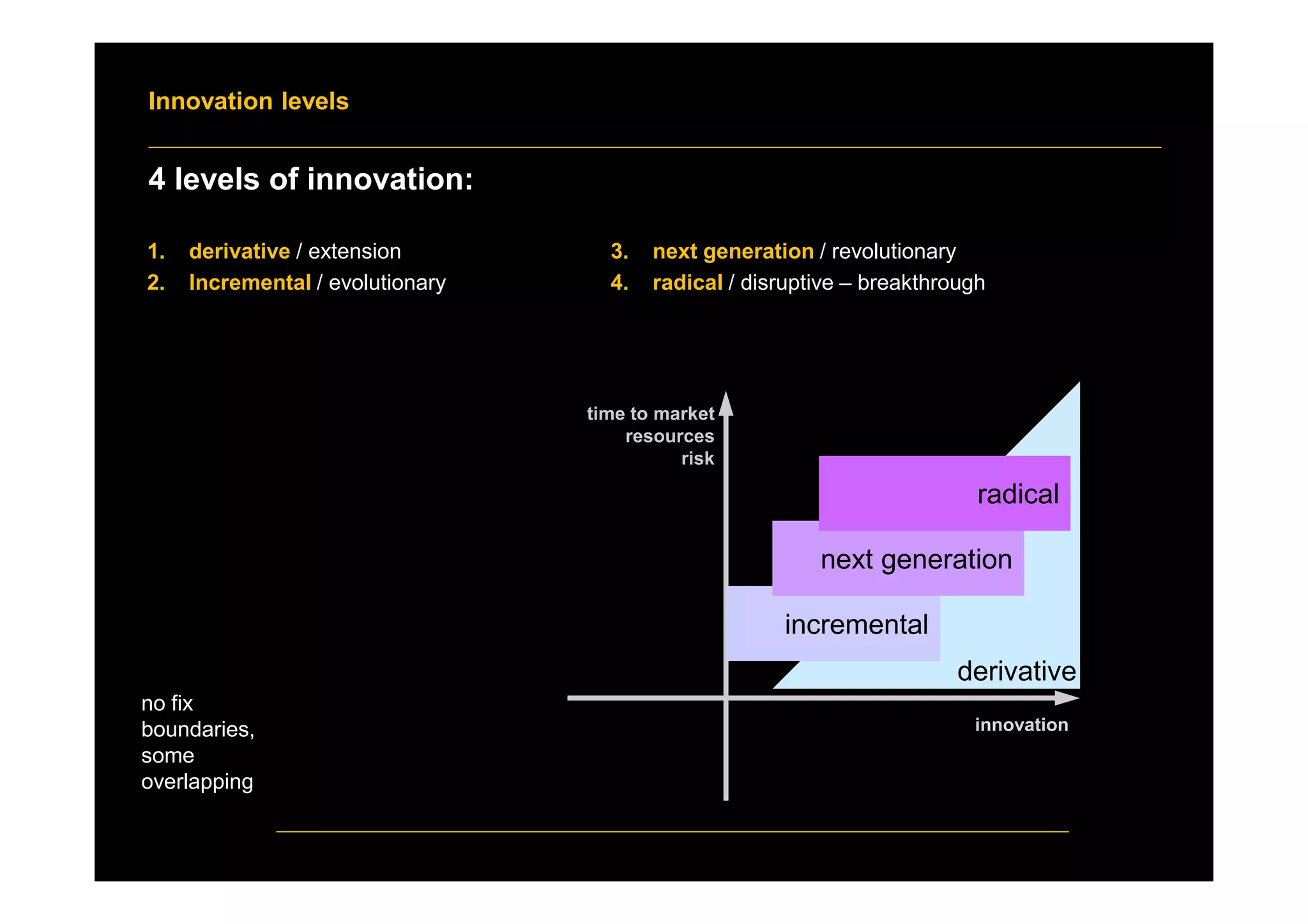

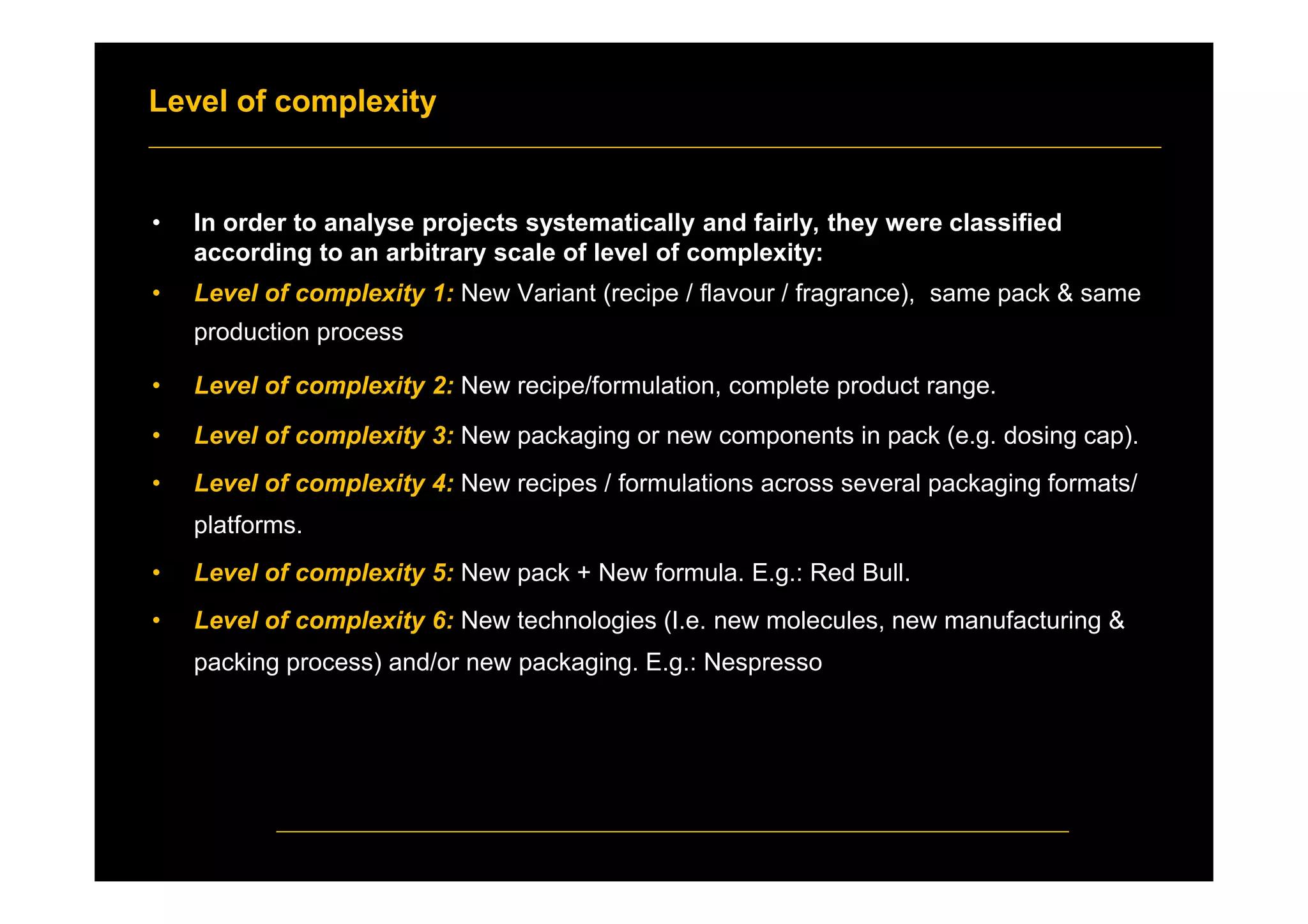

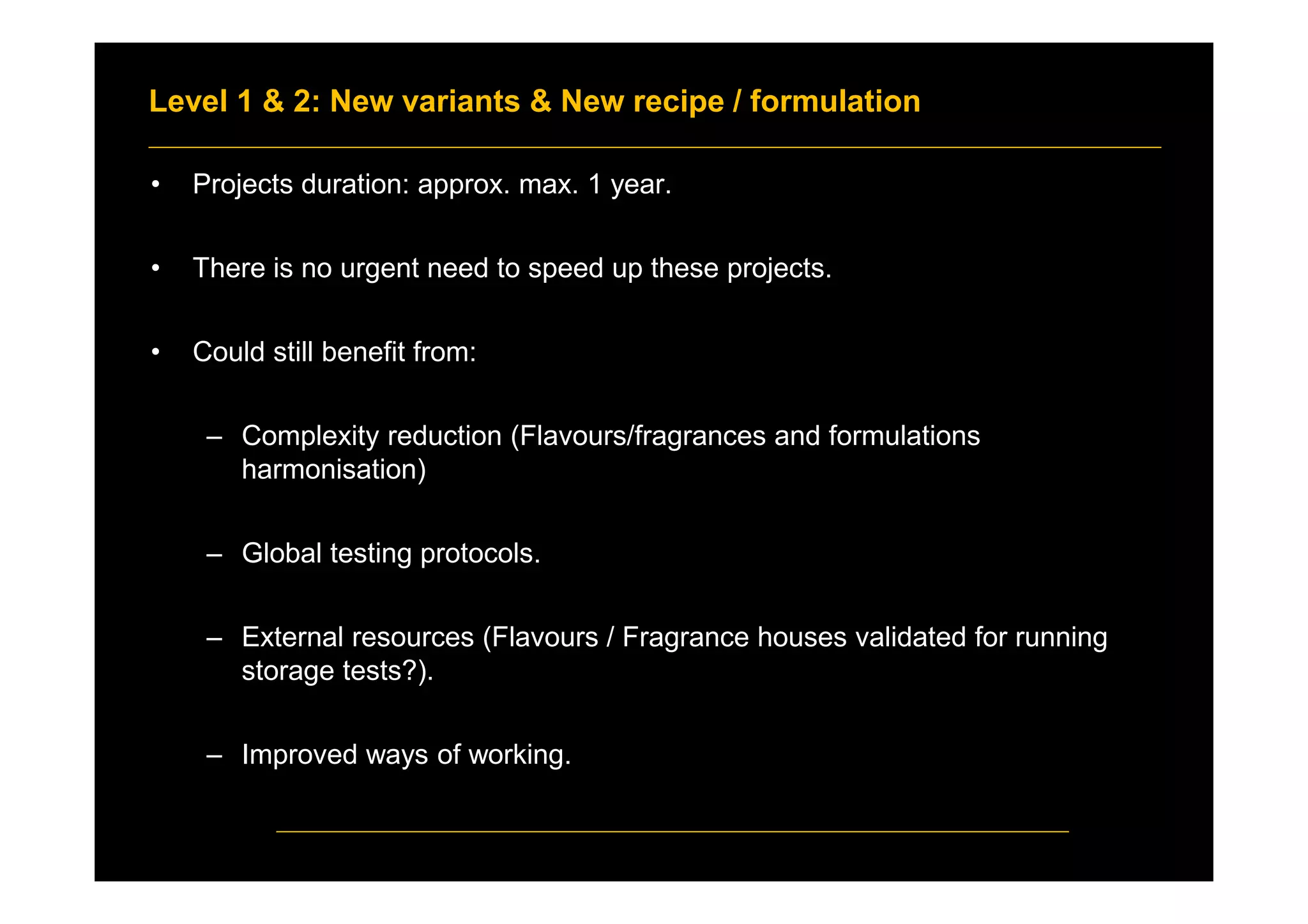

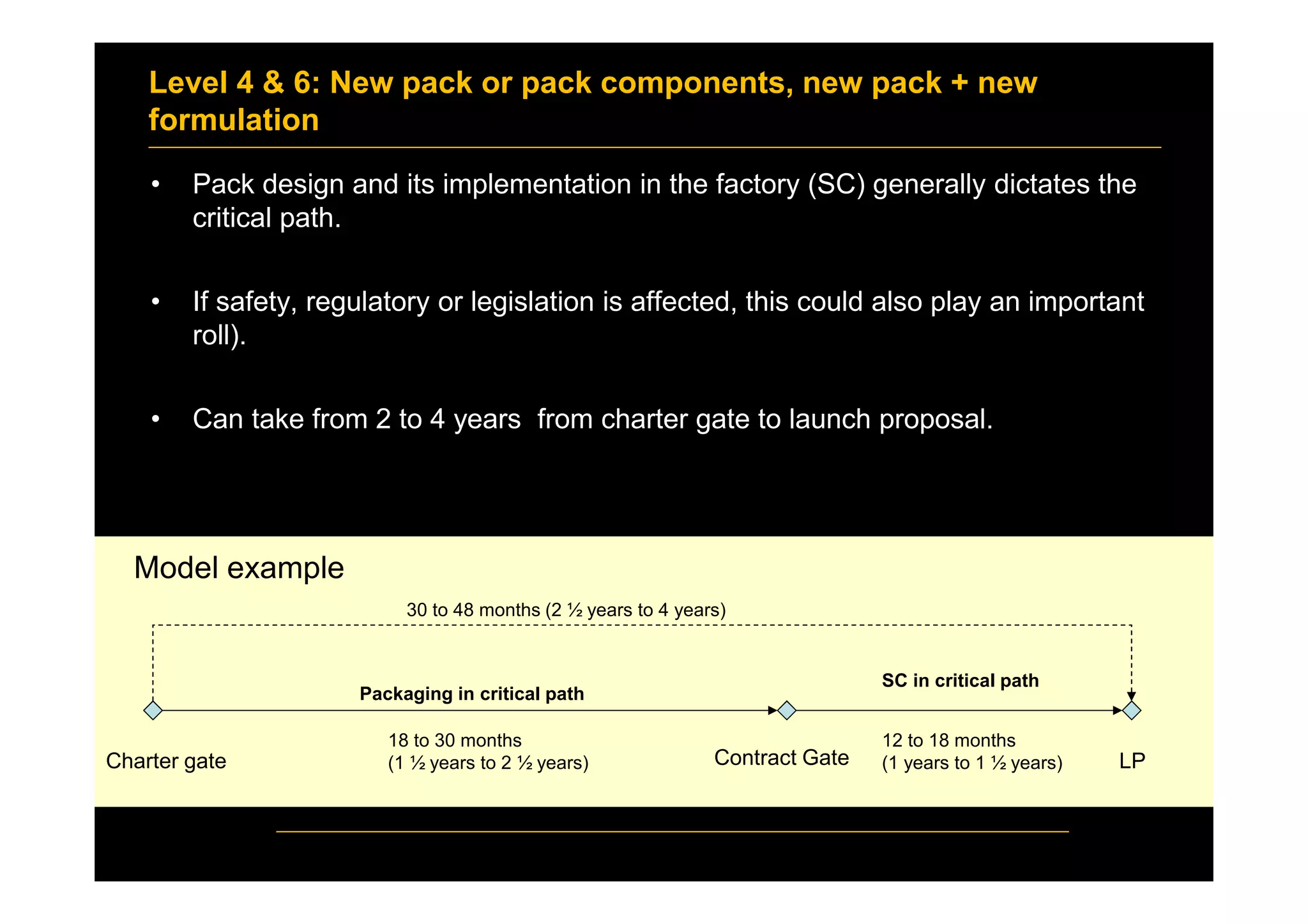

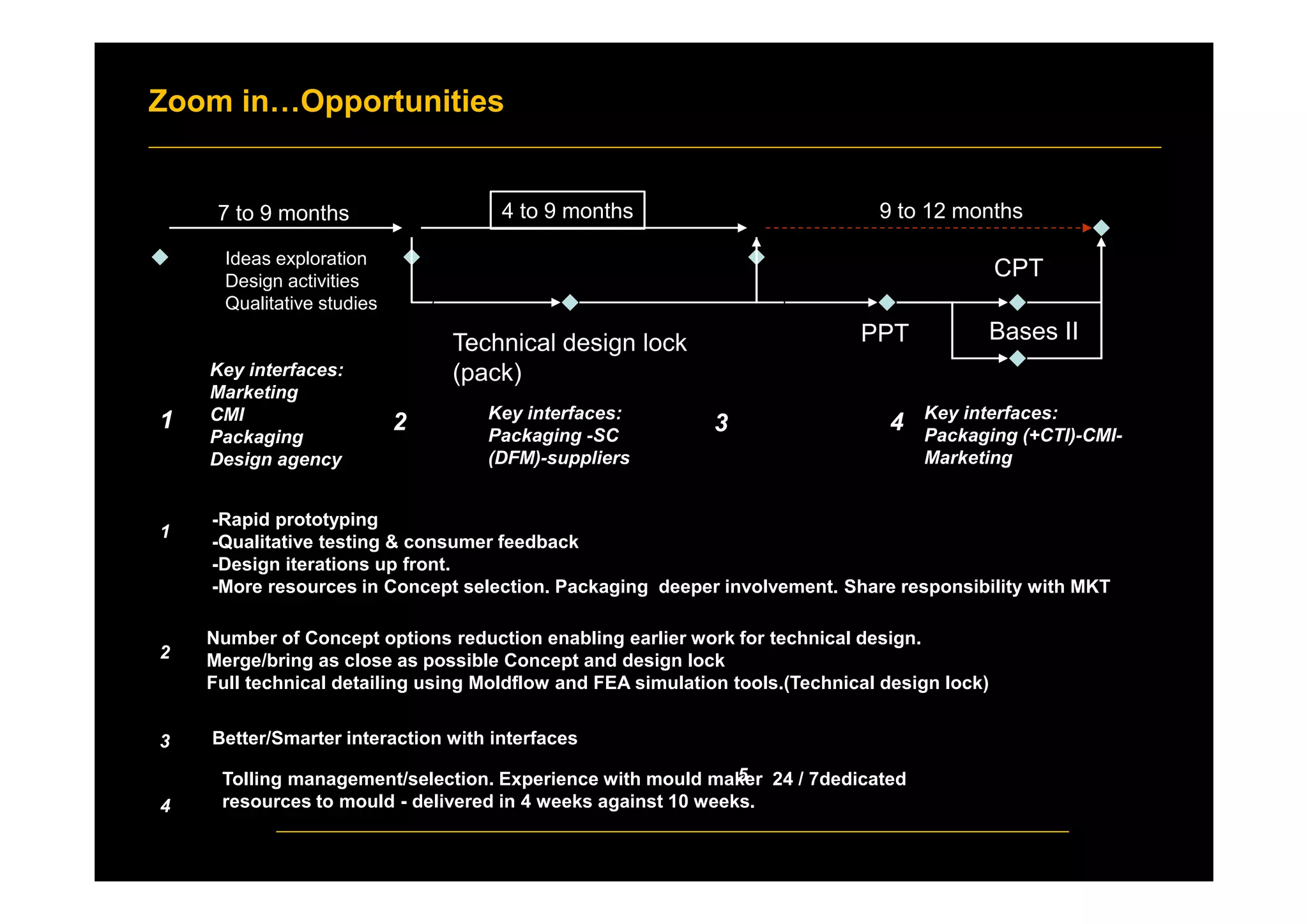

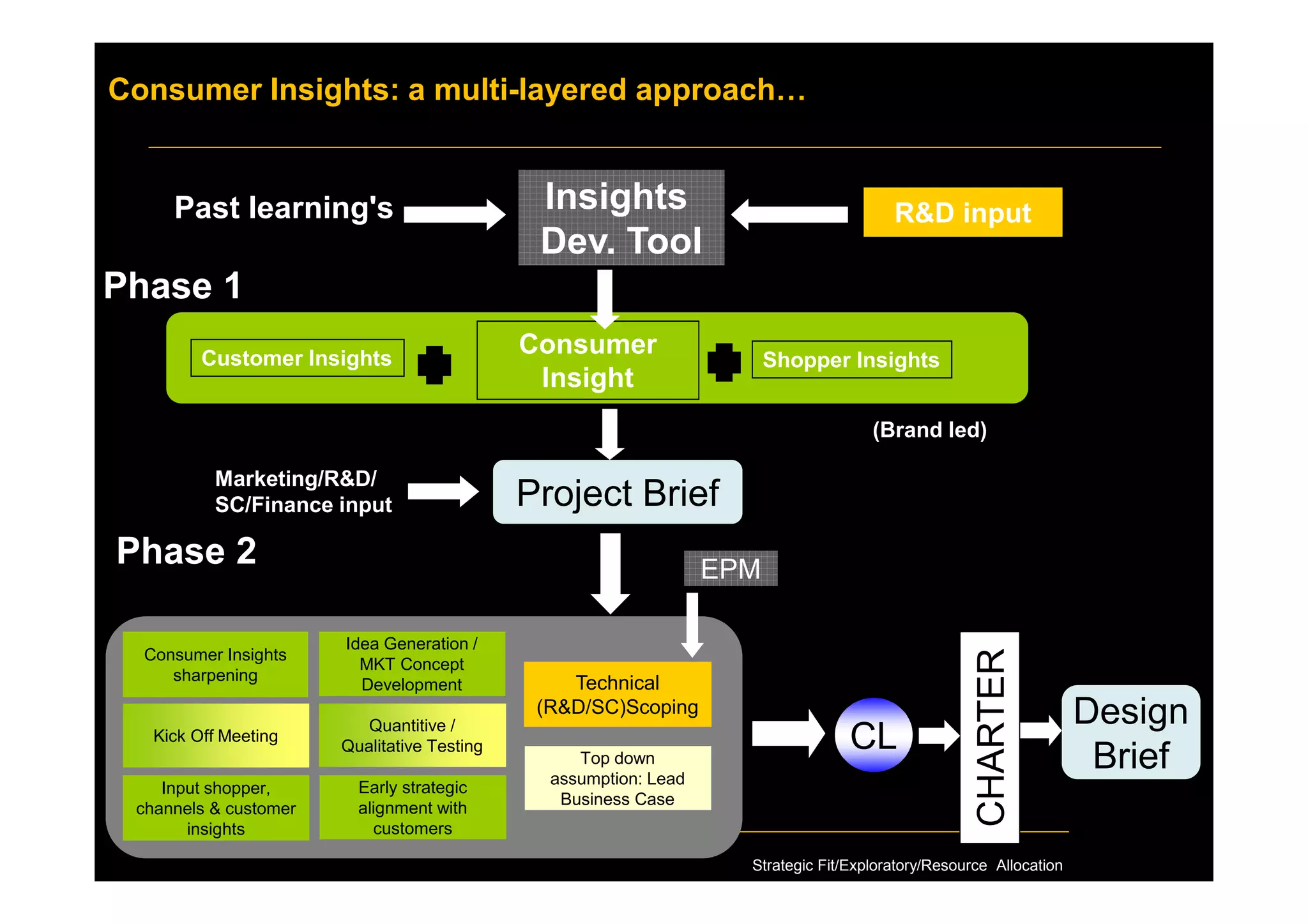

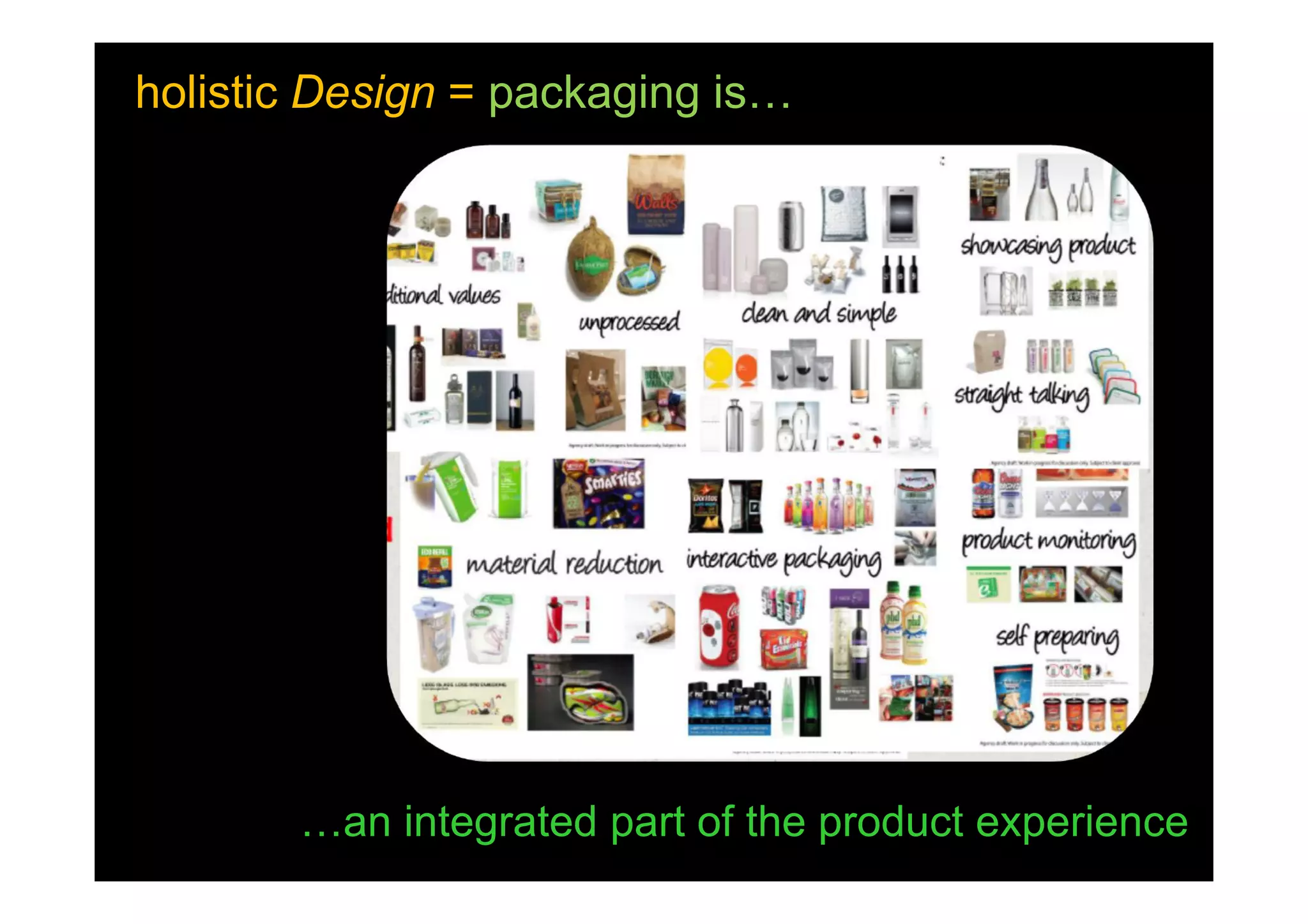

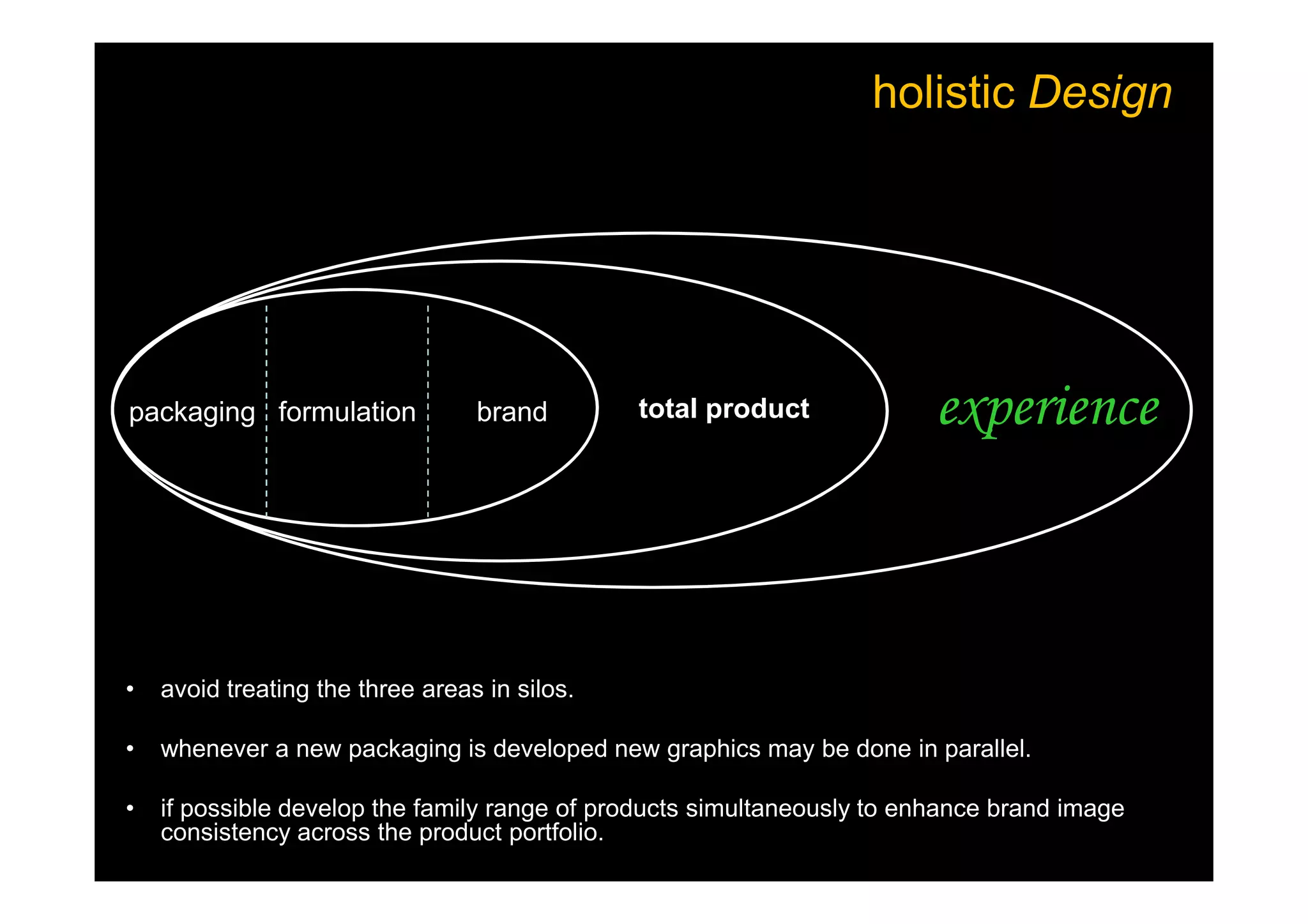

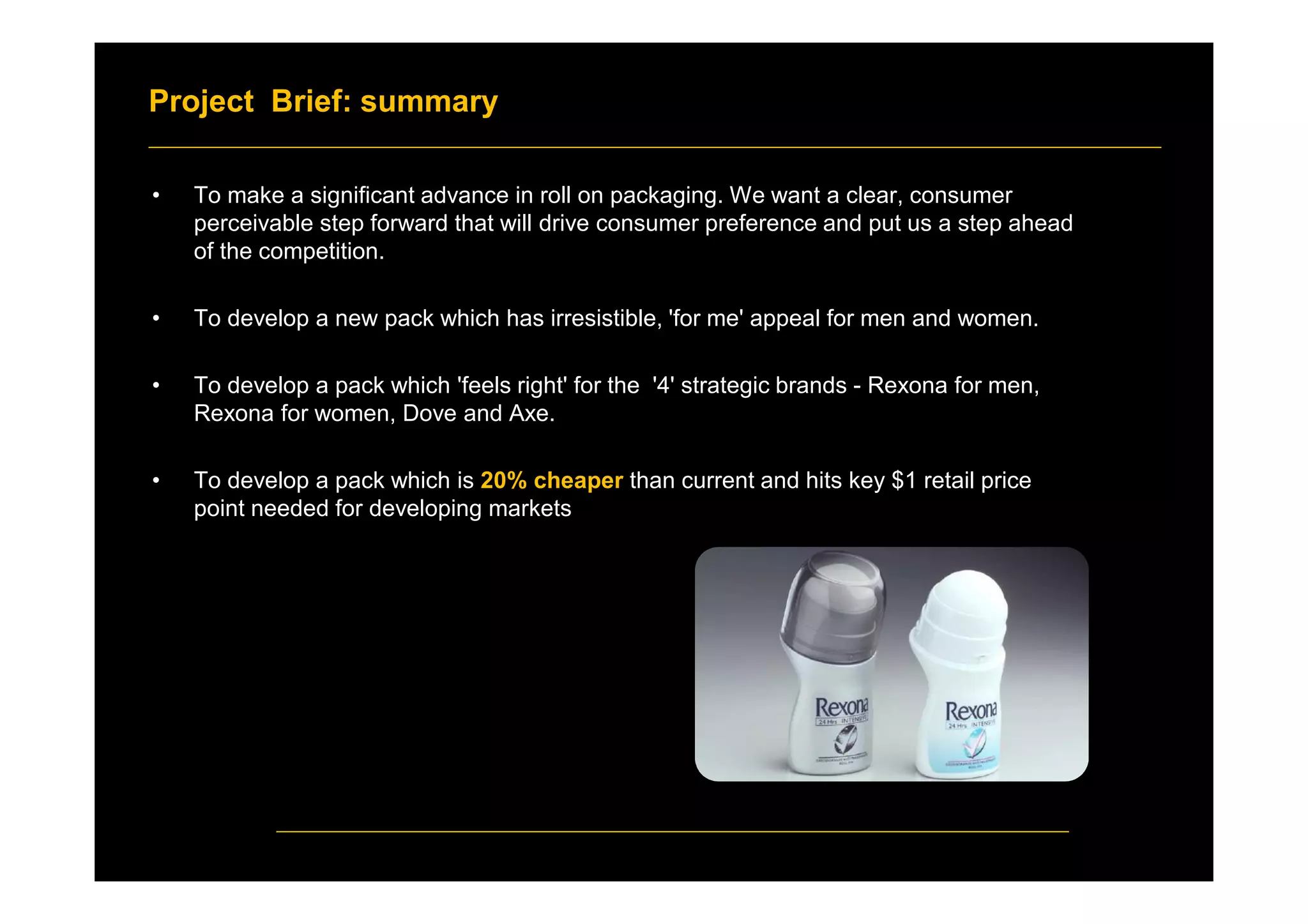

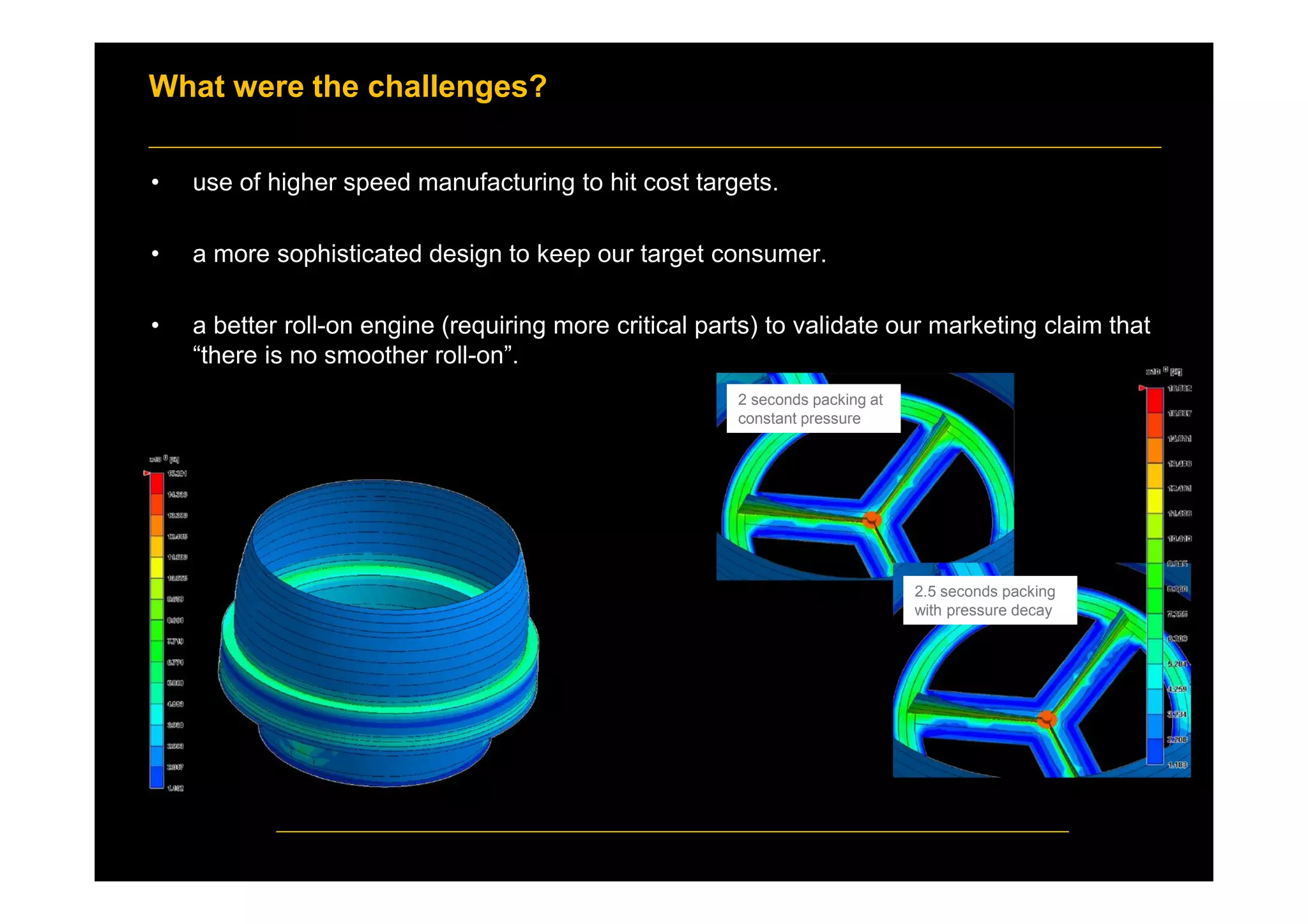

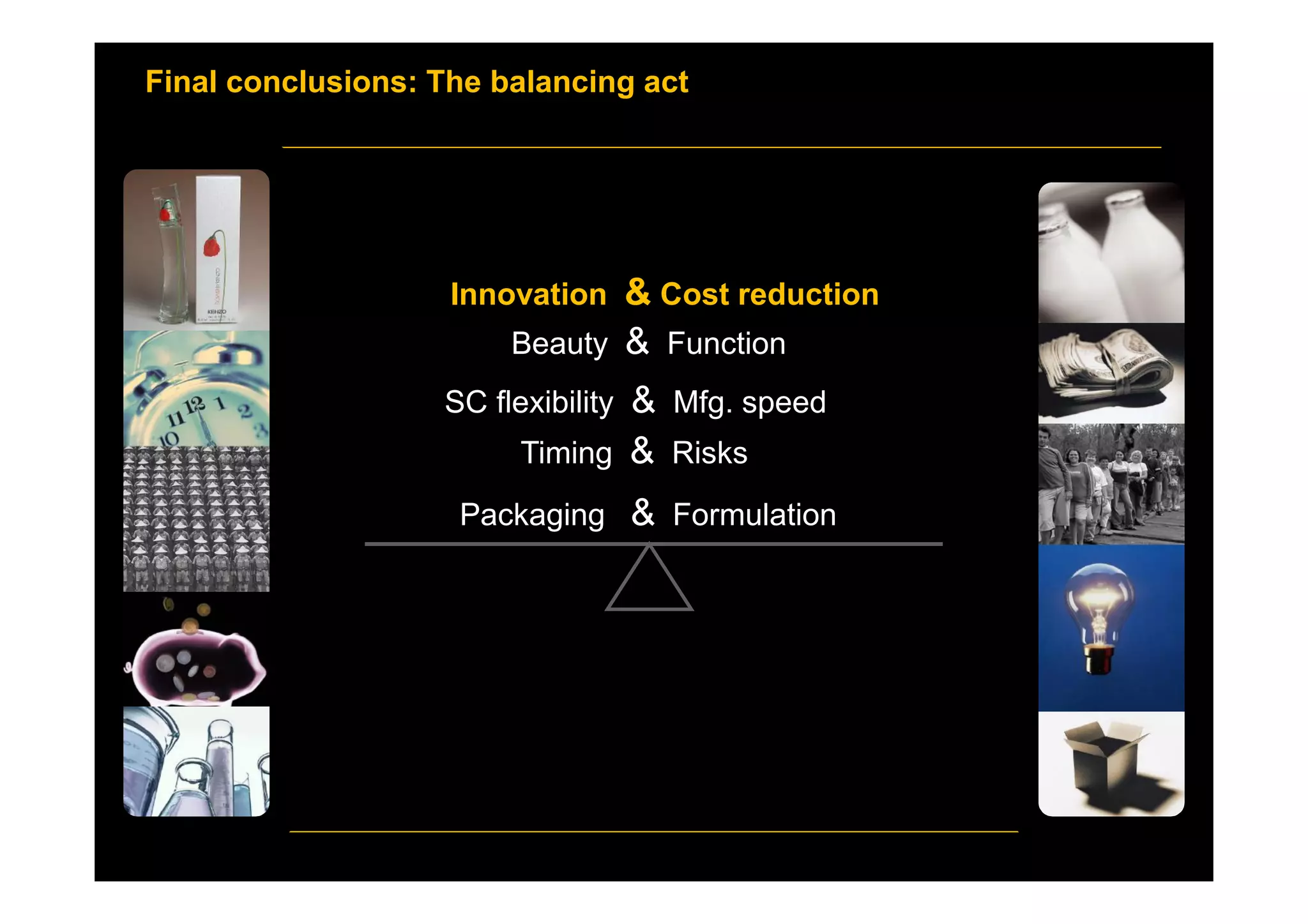

The document outlines the agenda and key learnings from the Pack InnoTech Conference 2013 in Thailand on packaging innovation. The conference discussed how innovation can lead to cost reduction through structural packaging design changes. It provided examples of different levels of innovation from incremental to radical and how projects are classified by complexity. A case study was presented on the development of an "upside-down" roll-on deodorant which achieved cost savings and performance improvements through cross-functional collaboration and redesign of the packaging, formulation and manufacturing process. The conference concluded that packaging innovation requires balancing structural design, costs, timing and risks while delivering beauty, function and the consumer experience.