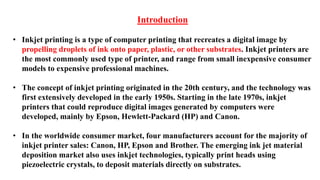

1. Inkjet printing is a type of computer printing that uses droplets of ink that are propelled from a nozzle onto paper. There are two main technologies, continuous inkjet and drop-on-demand inkjet.

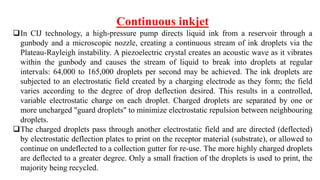

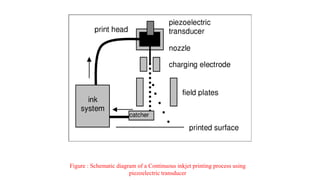

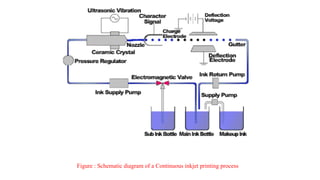

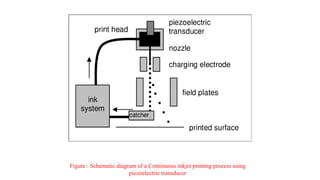

2. Continuous inkjet uses a high-pressure pump to create a continuous stream of ink droplets which are then electrostatically charged and deflected onto the paper. Drop-on-demand inkjet uses either a heating element or piezoelectric crystal to eject droplets only where they are needed.

3. Inkjet printers require mechanisms like printhead caps and cleaning cycles to prevent the nozzles from drying out and clogging. Advances in ink delivery systems include