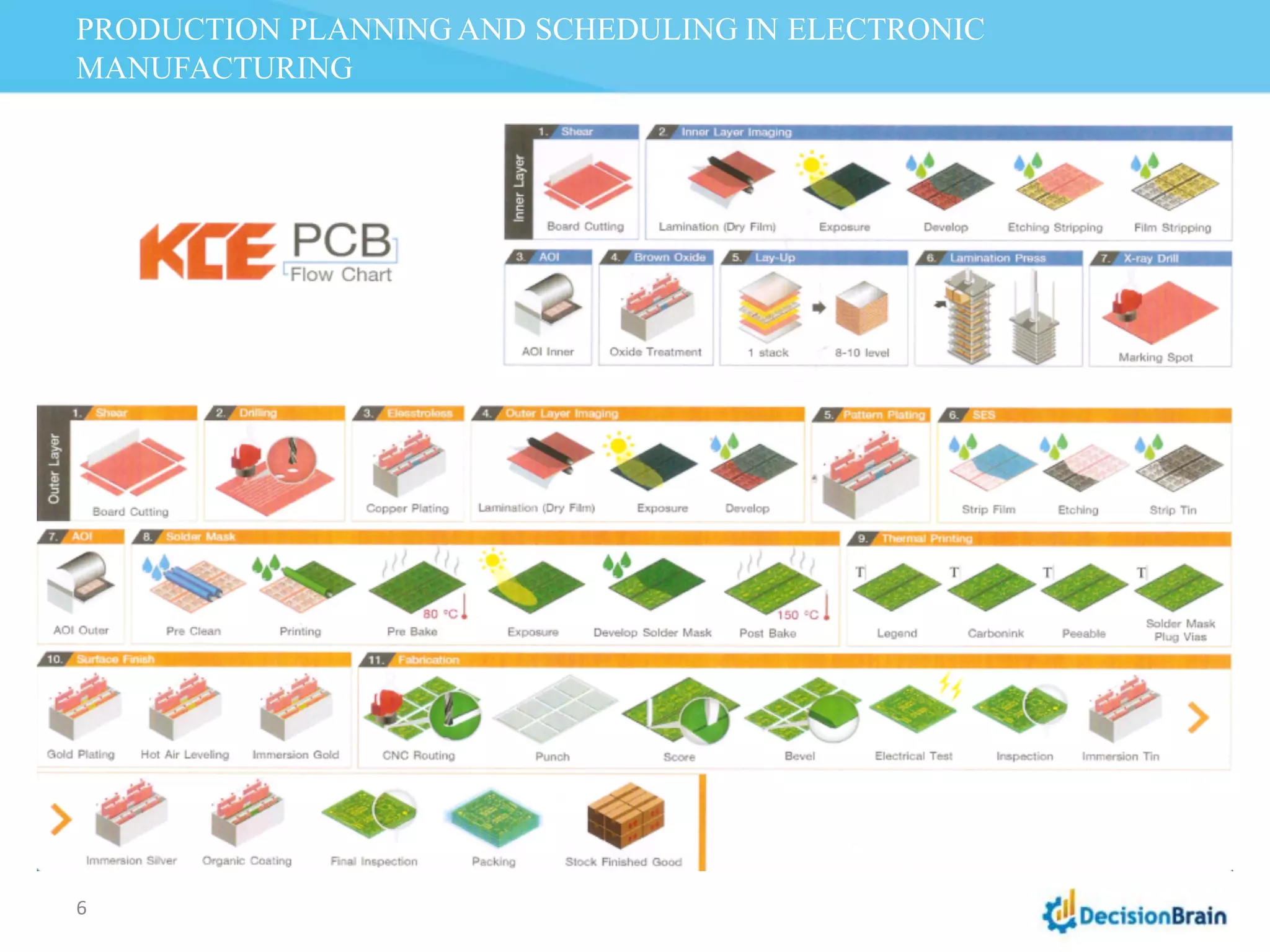

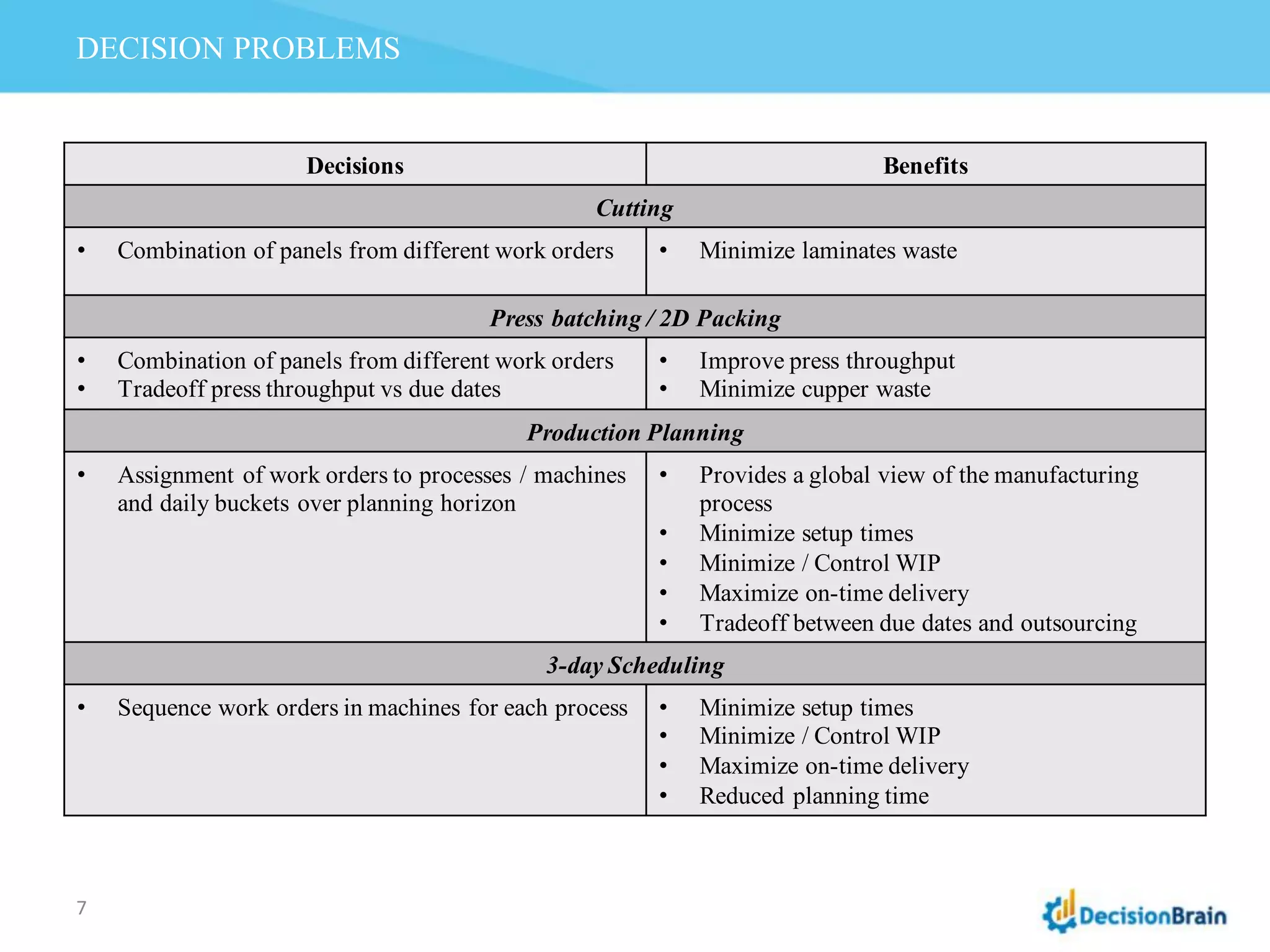

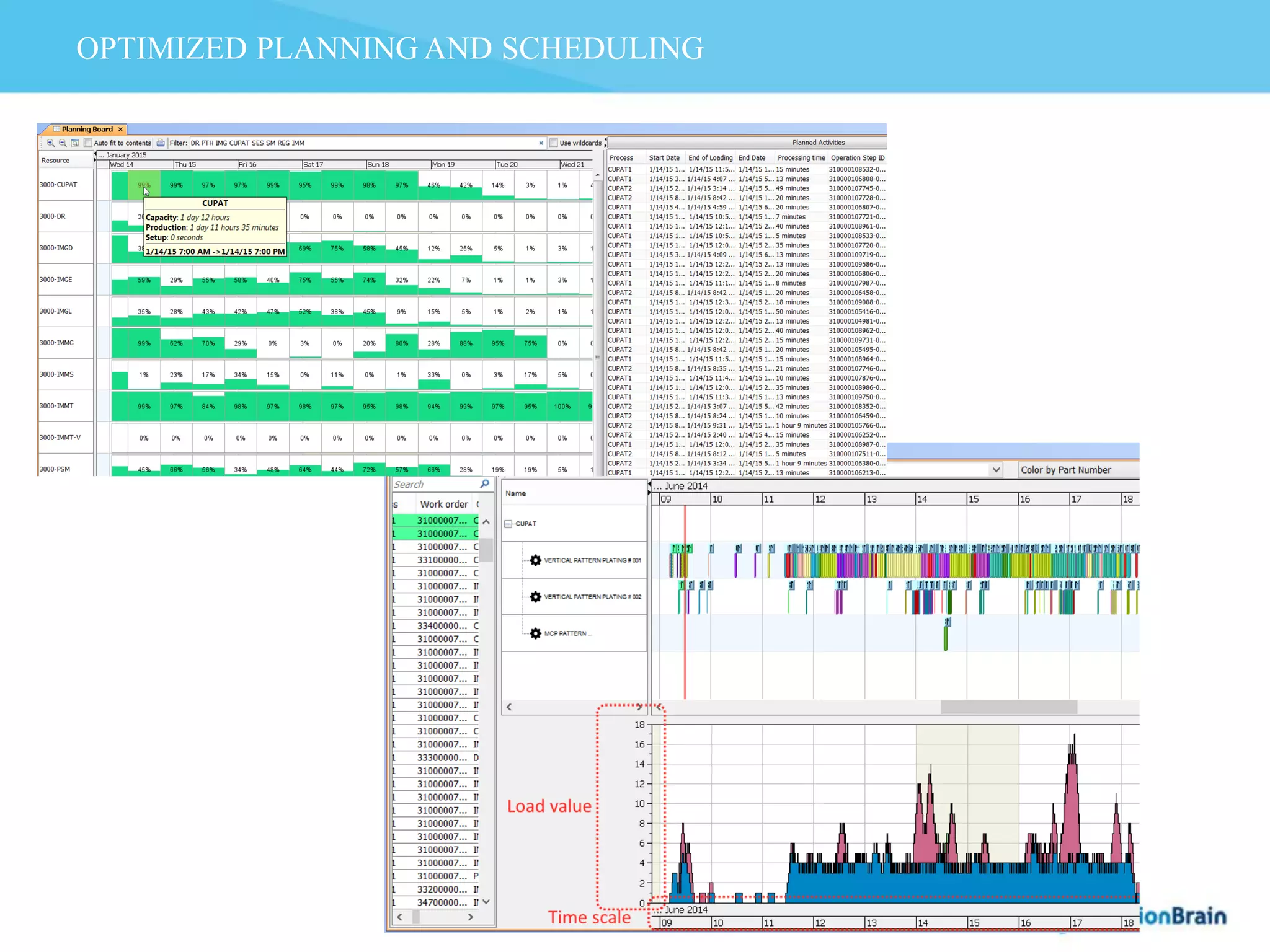

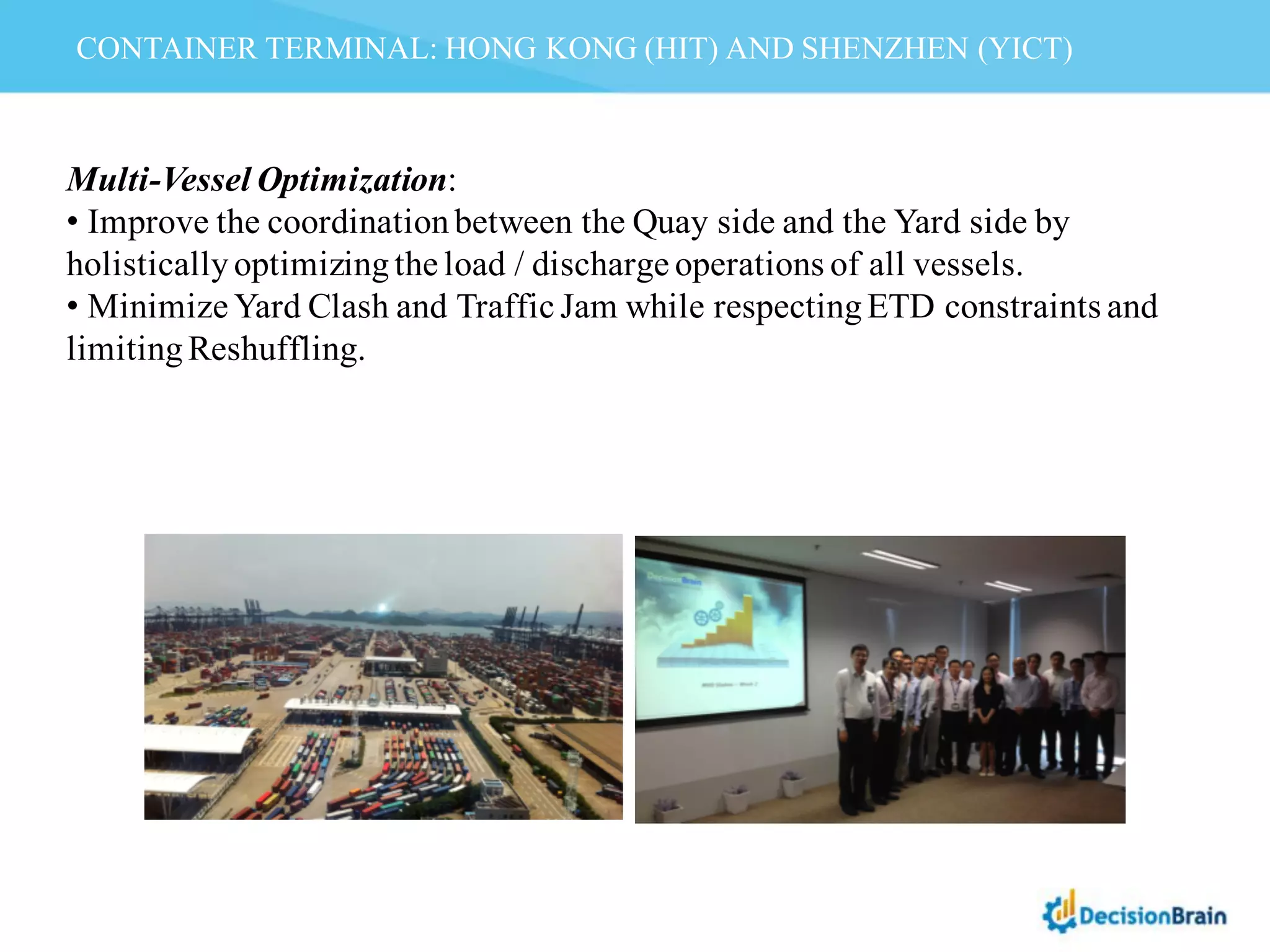

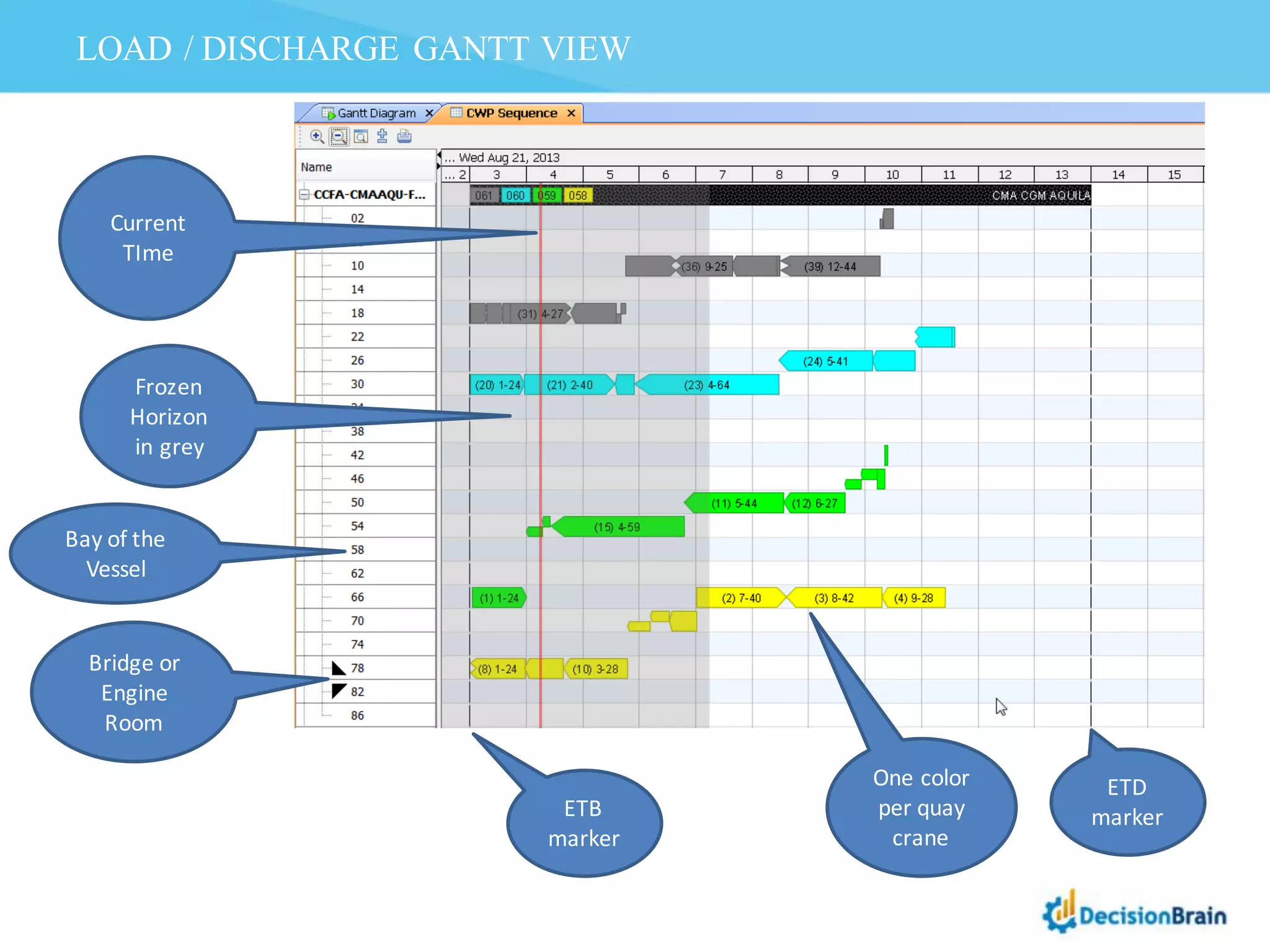

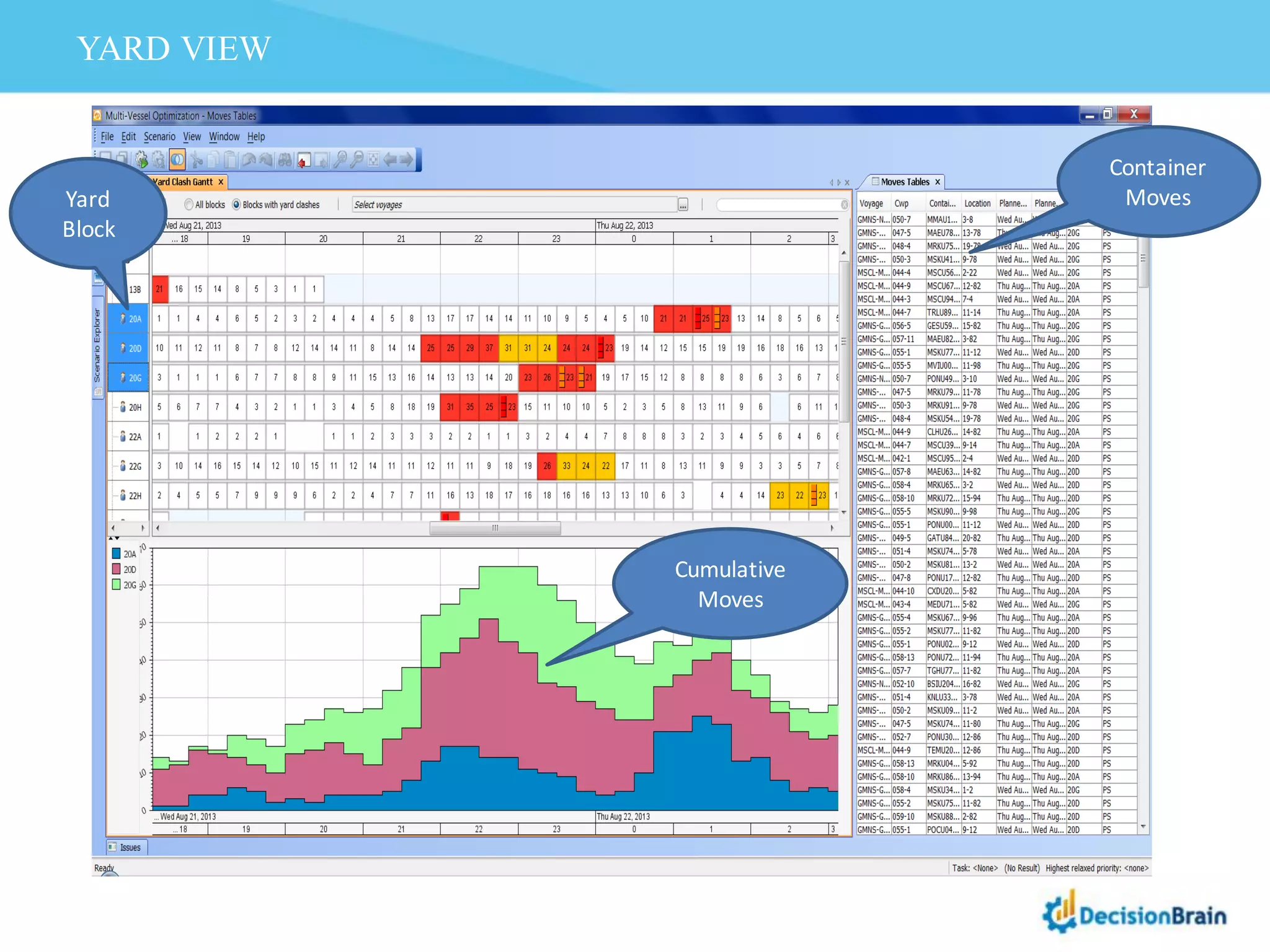

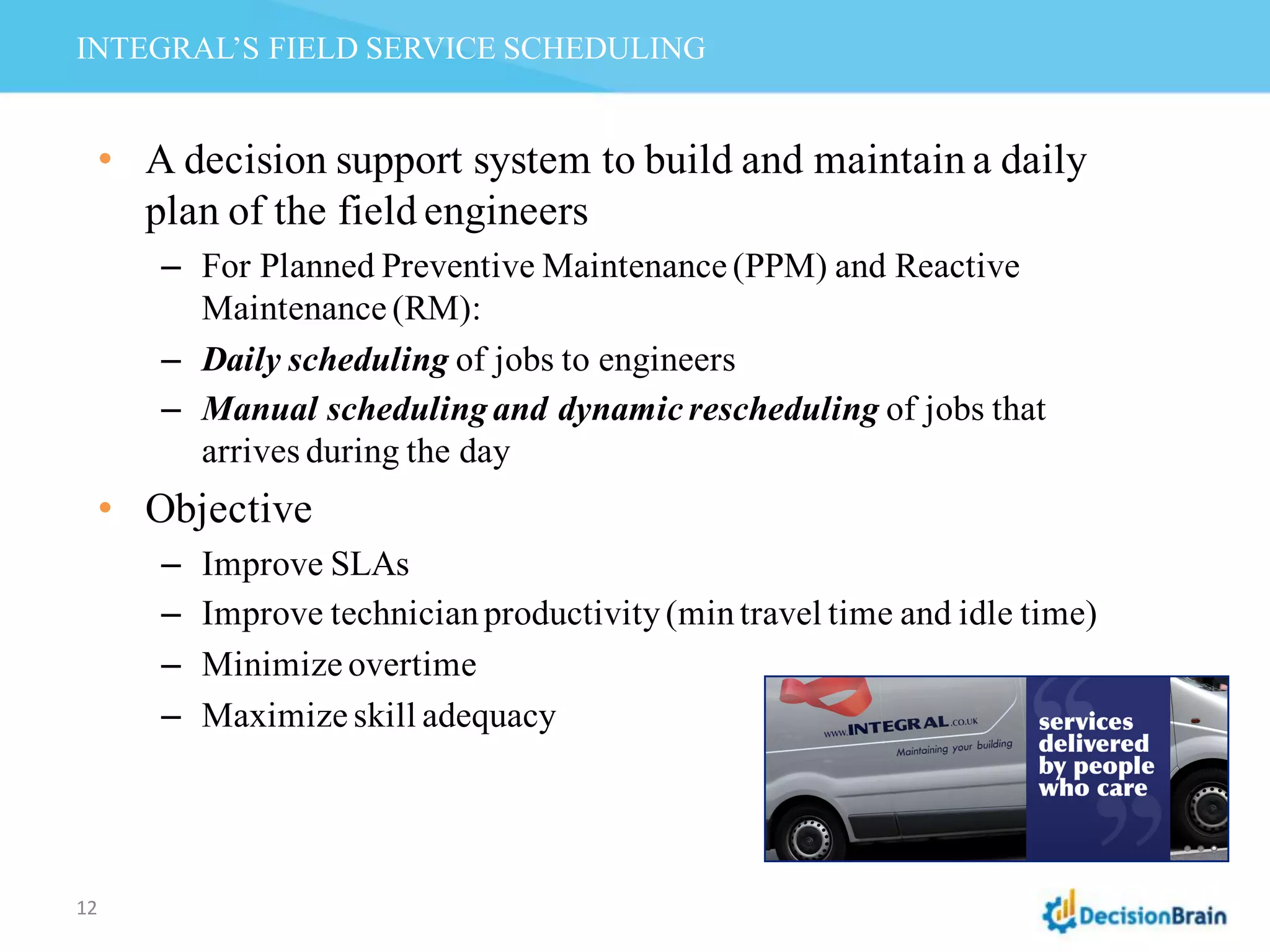

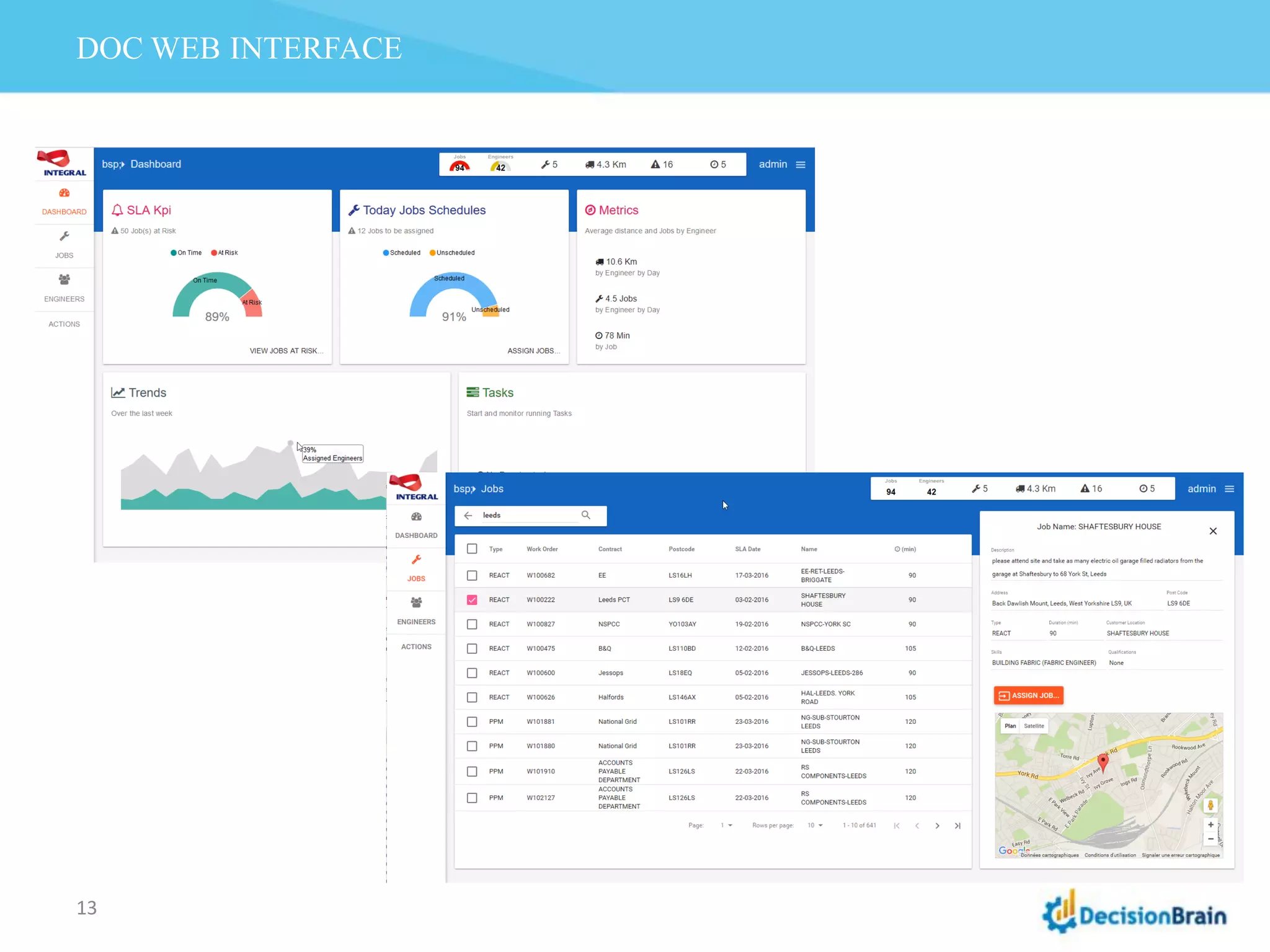

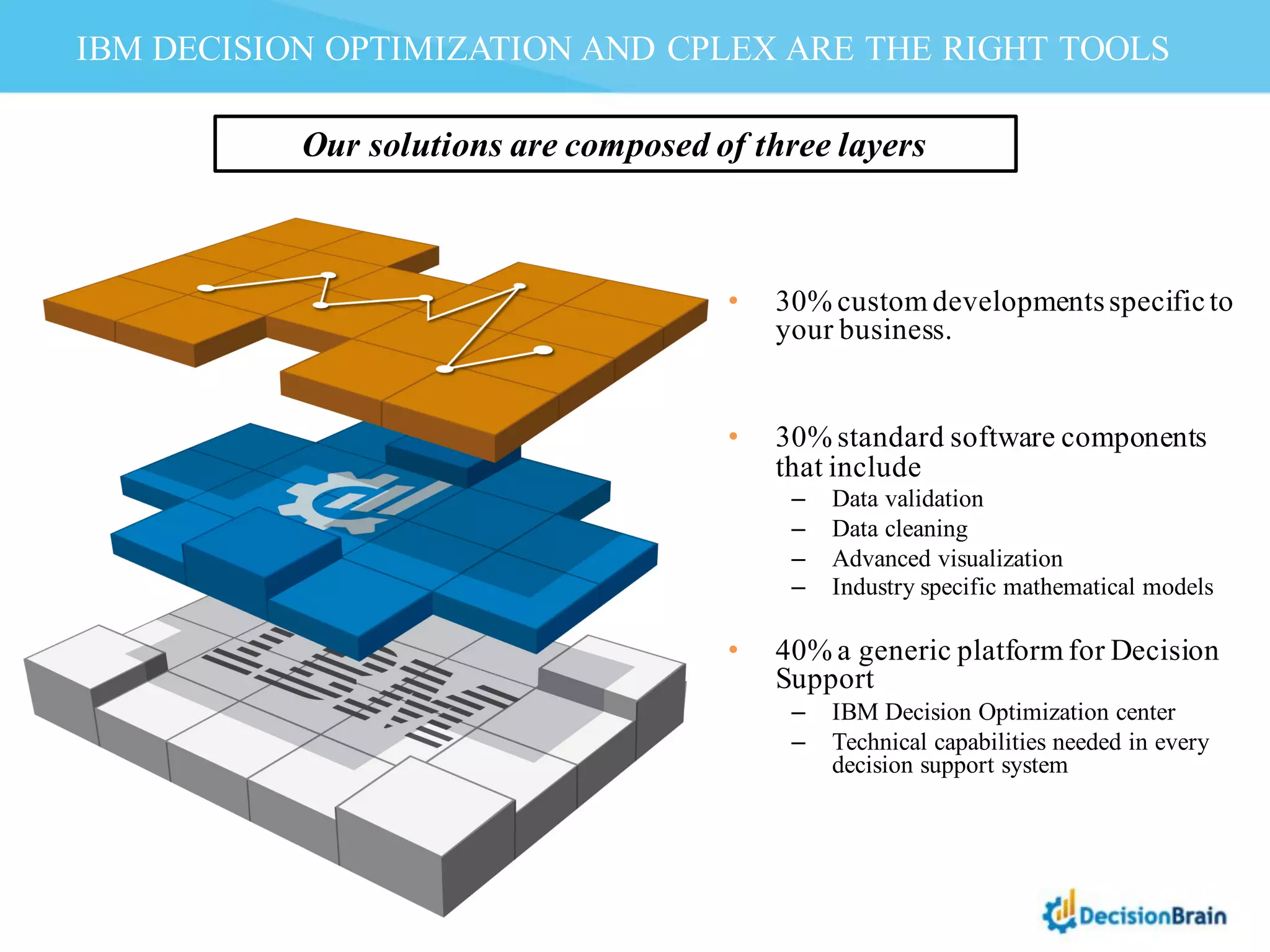

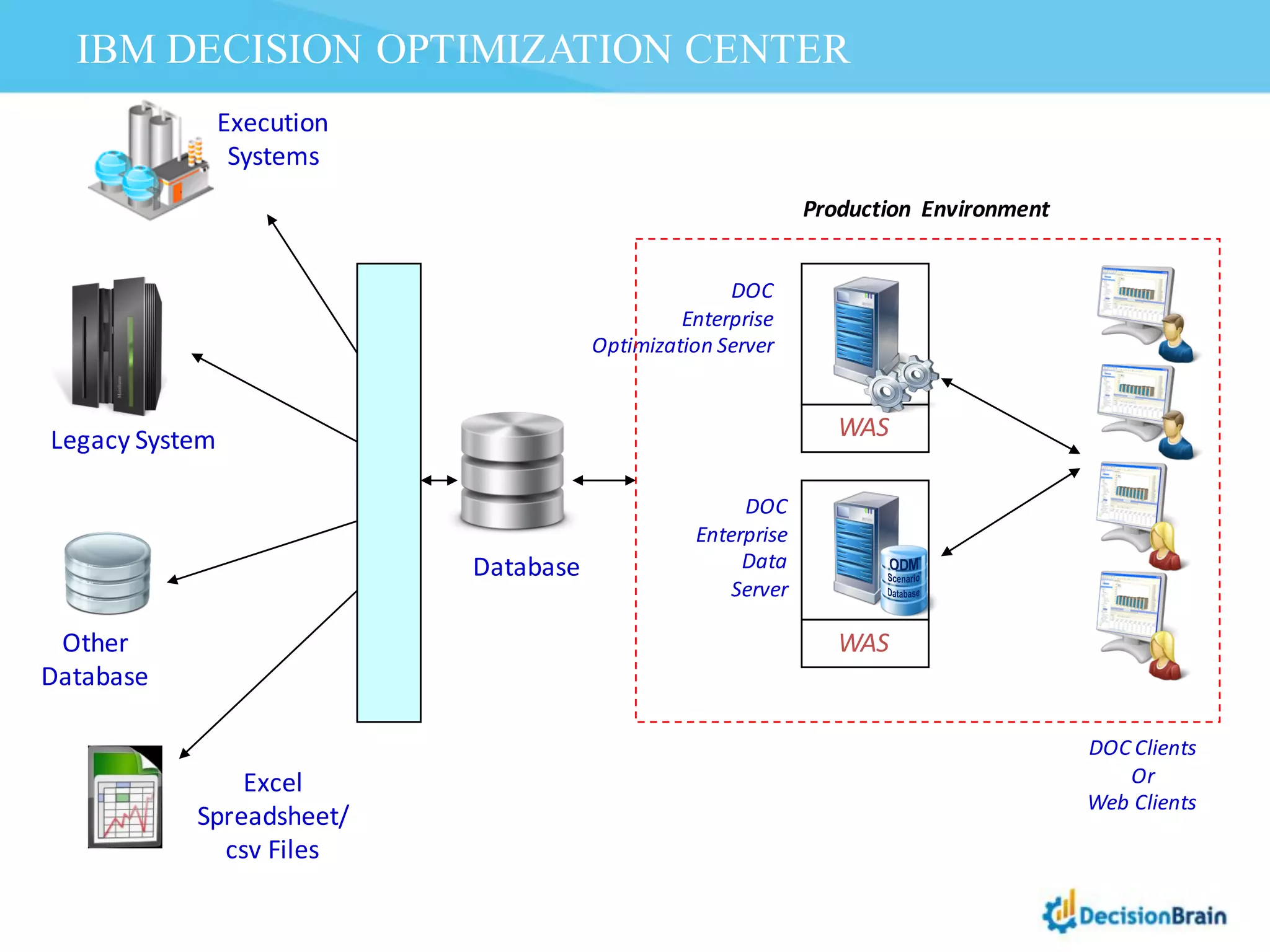

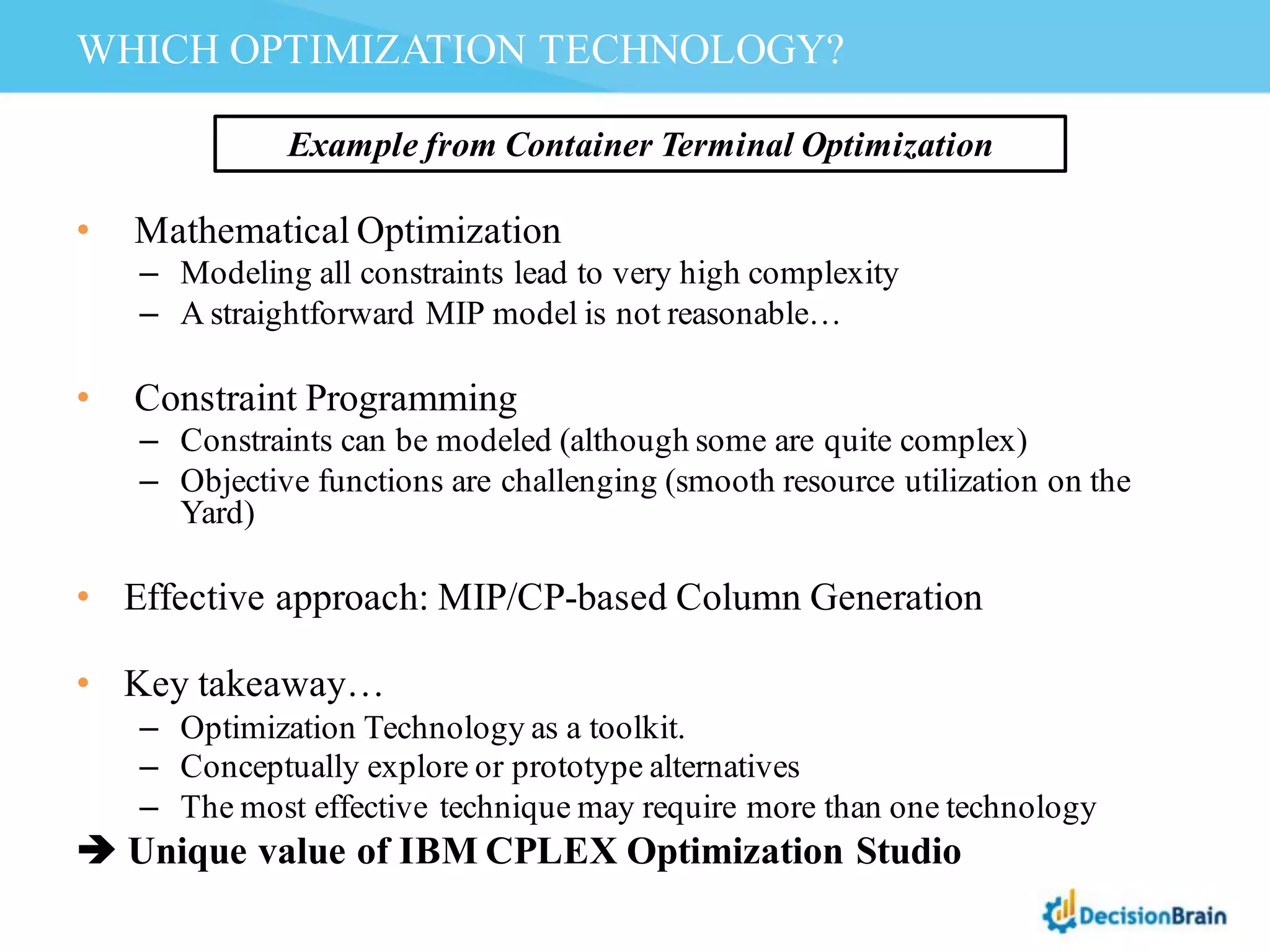

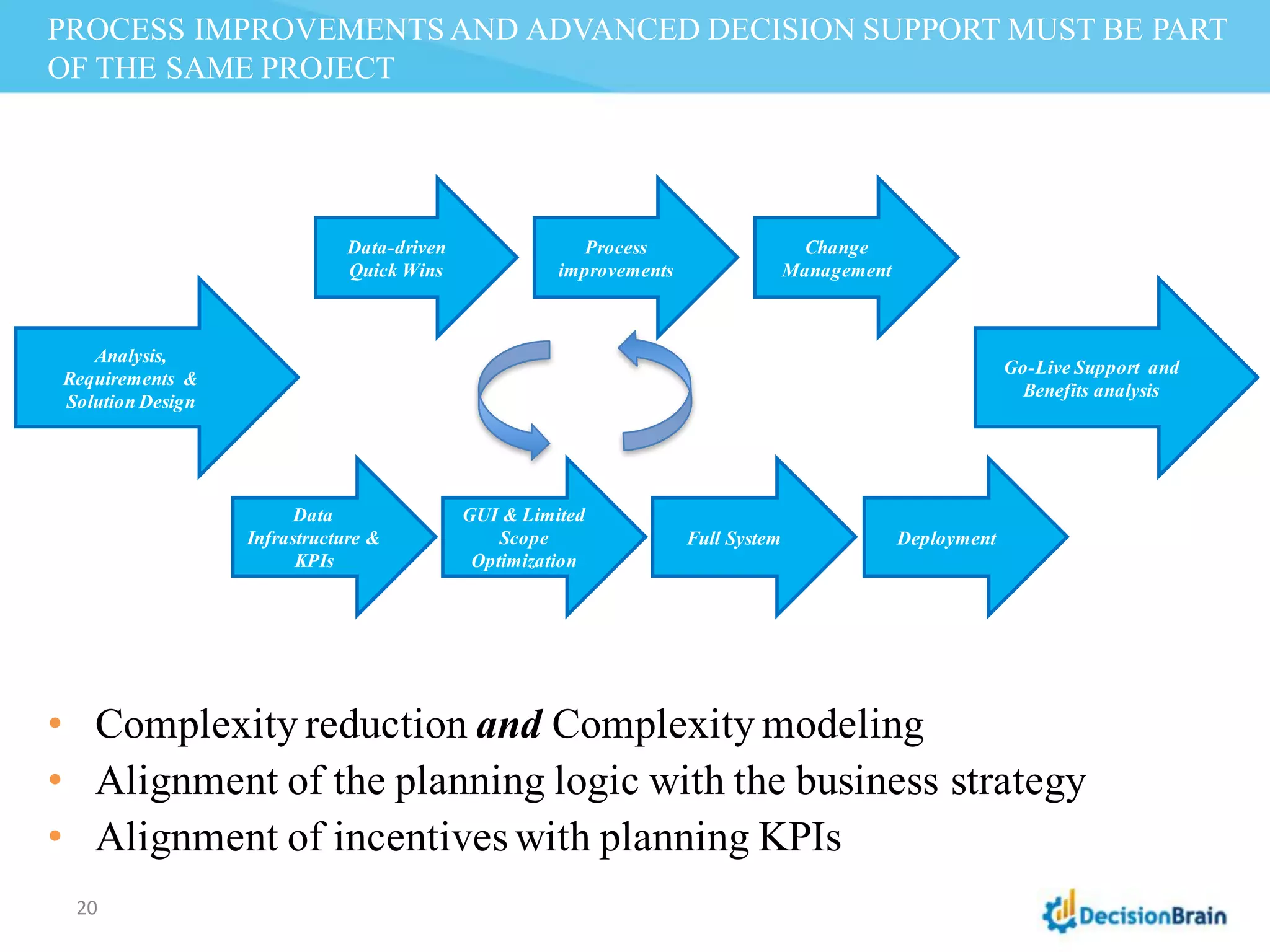

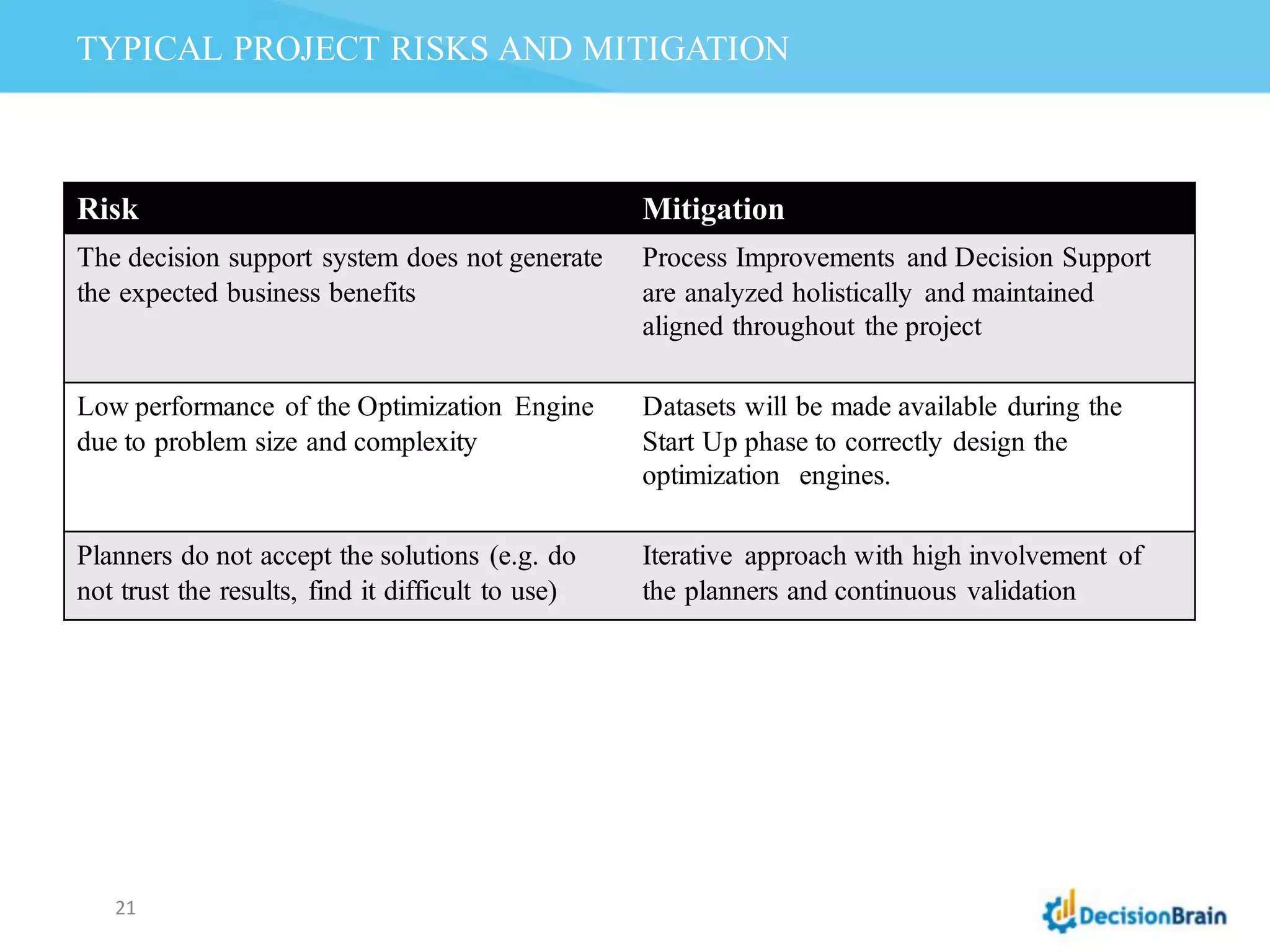

This document discusses optimization solutions for planning and scheduling problems using CPLEX. It begins with an introduction to DecisionBrain and examples of applications in manufacturing, supply chain, and maintenance scheduling. Case studies are presented on production planning in electronics manufacturing, container terminal optimization, and field service scheduling. Best practices are discussed around choosing the right optimization technology, emphasizing decision support over pure optimization, understanding business goals, and integrating process improvements with advanced decision support. Project risks around not achieving benefits, performance issues, and user acceptance are also addressed.