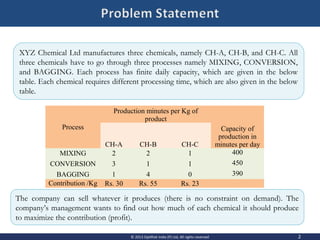

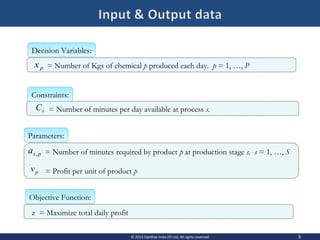

The document discusses a chemical company that manufactures three chemicals through three processes. It aims to determine the optimal production quantity of each chemical to maximize total daily profit. The processes have limited daily capacities. Each chemical requires different processing times and contributes different profits per kg. An optimization model is formulated to maximize the total contribution subject to the capacity constraints of each process.

![Objective function

Maximize Contribution

6© 2013 OptiRisk India (P) Ltd, All rights reserved

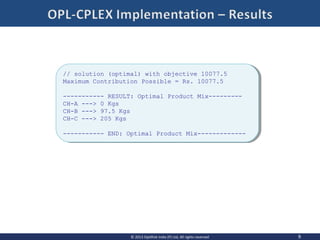

/*********************************************

* OPL 12.5 Model

* Author: OptiRisk

* Creation Date: 27-Aug-2013 at 10:02:32 AM

*********************************************/

// Input - indices

{string} Chemicals = ...;

{string} Processes = ...;

// Input parameters

float Capacity[Processes] = ...;

float ProcessTime[Chemicals][Processes] = ...;

float Contribution[Chemicals] = ...;

// Decision Variable

// Production Quantity of each Chemical

dvar float+ ChemicalQty[Chemicals];

// Objective Function

// Maximize total contribution

maximize

sum( p in Chemicals )

Contribution[p] * ChemicalQty[p];

Input Parameters

Decision Variables](https://image.slidesharecdn.com/productmixoptimizationcasestudy-130828000859-phpapp02/85/Product-Mix-Optimization-Case-Study-OPL-CPLEX-Code-6-320.jpg)

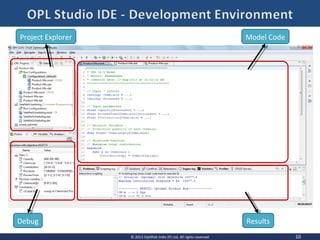

![Post Processing

Print Results

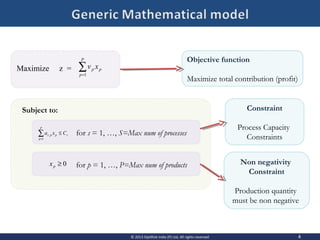

Constraint

Capacity Constraint

// Constraints

// 1. Capacity Constraints

subject to {

forall( s in Processes )

ctCapacity:

sum( p in Chemicals )

ProcessTime[p][s] * ChemicalQty[p] <= Capacity[s];

}

// Post processing to print results.

execute {

writeln("Maximum Contribution Possible = Rs. ",

cplex.getObjValue());

writeln("n----- RESULT: Optimal Product Mix---------");

// Print the optimal product quantities.

for( var p in Chemicals){

writeln(p, " ---> ", ChemicalQty[p], " Kgs");

}

writeln("n---- END: Optimal Product Mix-------------");

}

7© 2013 OptiRisk India (P) Ltd, All rights reserved](https://image.slidesharecdn.com/productmixoptimizationcasestudy-130828000859-phpapp02/85/Product-Mix-Optimization-Case-Study-OPL-CPLEX-Code-7-320.jpg)

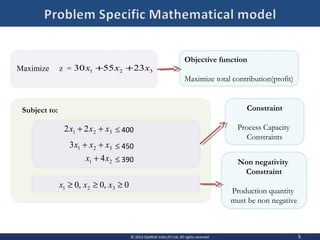

![Input Data

Parameters

Index

/*********************************************

* OPL 12.5 Data

* Author: OptiRisk

* Creation Date: 27-Aug-2013 at 10:02:32 AM

*********************************************/

Chemicals = {"CH-A","CH-B","CH-C"};

Processes = {"MIXING", "CONVERSION", "BAGGING"};

// Capacity in minutes of each process

Capacity = [400, 450, 390];

// Processing time for each chemical, for every process

ProcessTime = [[2,3,1],[2,1,4],[1,1,0]];

// Contribution (profit) for each chemical

Contribution = [30, 55, 23];

8© 2013 OptiRisk India (P) Ltd, All rights reserved](https://image.slidesharecdn.com/productmixoptimizationcasestudy-130828000859-phpapp02/85/Product-Mix-Optimization-Case-Study-OPL-CPLEX-Code-8-320.jpg)