This document discusses modeling and solving partial differential equations (PDEs) using the Industrial Modeling Framework (IMF). It presents a sample 1D heat transfer PDE problem and models it using finite difference (FD) and orthogonal collocation (OC) methods. The results show good agreement between the two methods. IMPL can model both dynamic and spatially distributed problems by discretizing across time and space to obtain algebraic equations that can then be optimized.

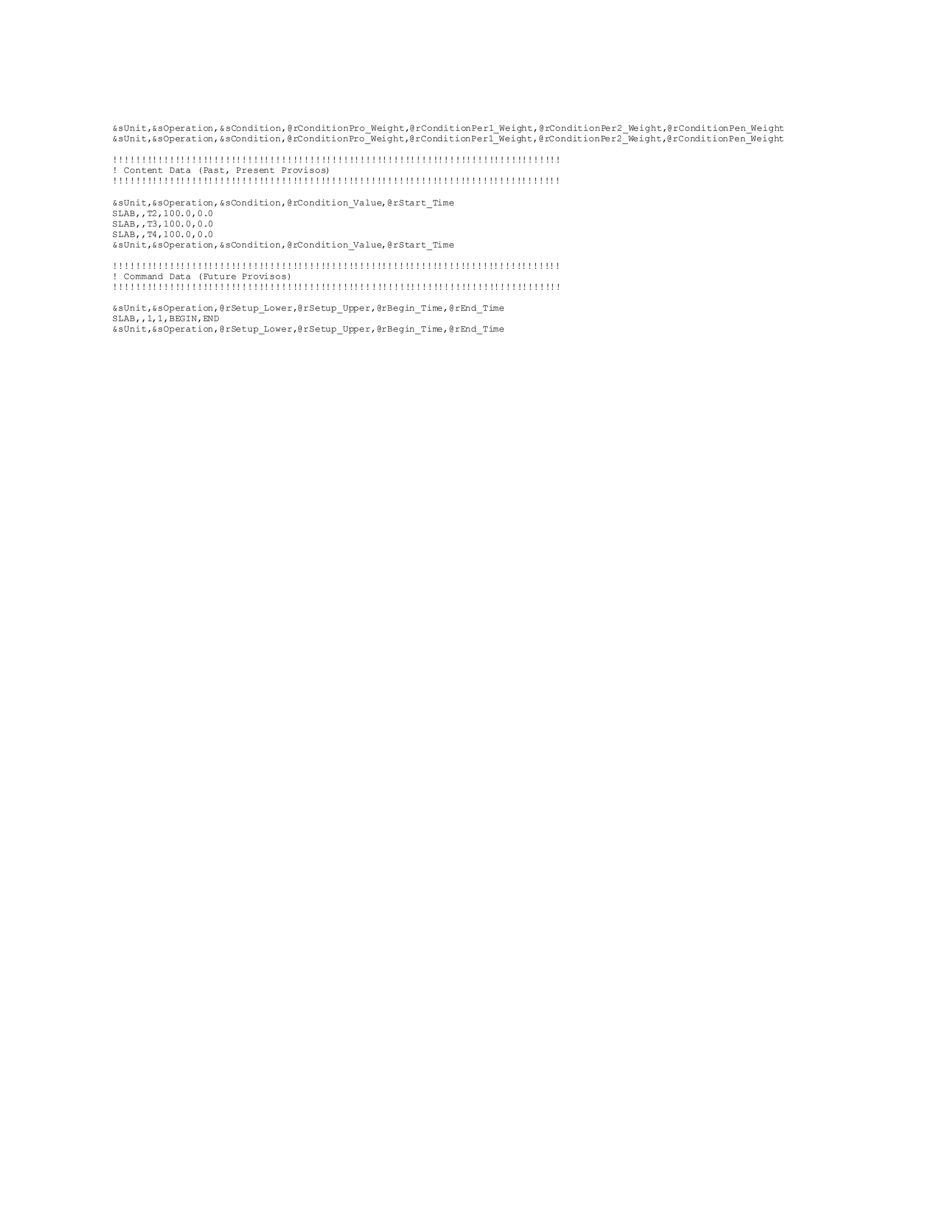

![!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

&sCalc,@sValue

PERIOD,1.0

START,-PERIOD

BEGIN,0.0

END,6000.0

dx,0.1

&sCalc,@sValue

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Chronological Data (Periods)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

@rPastTHD,@rFutureTHD,@rTPD

START,END,PERIOD

@rPastTHD,@rFutureTHD,@rTPD

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Construction Data (Pointers)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

&sUnit,&sOperation,@sType,@sSubtype,@sUse

SLAB,,processc,blackbox,,

&sUnit,&sOperation,@sType,@sSubtype,@sUse

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Condition Data (Properties)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

&sCondition

T1

T2

T3

T4

T5

T6

T7

T8

T9

T10

T11

eqT2

eqT3

eqT4

eqT5

eqT6

eqT7

eqT8

eqT9

eqT10

&sCondition

&sCoefficient,@sType,@sPath_Name,@sLibrary_Name,@sFunction_Name,@iNumber_Conditions,@rPerturb_Size,@sCondition_Names

a,static

&sCoefficient,@sType,@sPath_Name,@sLibrary_Name,@sFunction_Name,@iNumber_Conditions,@rPerturb_Size,@sCondition_Names

&sUnit,&sOperation,&sCondition,@rCondition_Lower,@rCondition_Upper,@rCondition_Target

SLAB,,T1,0.0,0.0,

SLAB,,T2,0.0,200.0,

SLAB,,T3,0.0,200.0,

SLAB,,T4,0.0,200.0,

SLAB,,T5,0.0,200.0,

SLAB,,T6,0.0,200.0,

SLAB,,T7,0.0,200.0,

SLAB,,T8,0.0,200.0,

SLAB,,T9,0.0,200.0,

SLAB,,T10,0.0,200.0,

SLAB,,T11,0.0,200.0,

SLAB,,eqT2,0.0,0.0,

SLAB,,eqT3,0.0,0.0,

SLAB,,eqT4,0.0,0.0,

SLAB,,eqT5,0.0,0.0,

SLAB,,eqT6,0.0,0.0,

SLAB,,eqT7,0.0,0.0,

SLAB,,eqT8,0.0,0.0,

SLAB,,eqT9,0.0,0.0,

SLAB,,eqT10,0.0,0.0,

&sUnit,&sOperation,&sCondition,@rCondition_Lower,@rCondition_Upper,@rCondition_Target

&sUnit,&sOperation,&sCoefficient,@rCoefficient_Lower,@rCoefficient_Upper,@rCoefficient_Target

SLAB,,a,2.0E-5,2.0E-5,

&sUnit,&sOperation,&sCoefficient,@rCoefficient_Lower,@rCoefficient_Upper,@rCoefficient_Target

ConditionsUOCondition-&sUnit,&sOperation,&sCondition,@sType,@rValue,@sValue

SLAB,,eqT2,?,3,T2 - T2[-1] - a / dx^2.0 * (T3-2.0*T2+T1) * PERIOD

SLAB,,eqT3,?,3,T3 - T3[-1] - a / dx^2.0 * (T4-2.0*T3+T2) * PERIOD

SLAB,,eqT4,?,3,T4 - T4[-1] - a / dx^2.0 * (T5-2.0*T4+T3) * PERIOD

SLAB,,eqT5,?,3,T5 - T5[-1] - a / dx^2.0 * (T6-2.0*T5+T4) * PERIOD

SLAB,,eqT6,?,3,T6 - T6[-1] - a / dx^2.0 * (T7-2.0*T6+T5) * PERIOD

SLAB,,eqT7,?,3,T7 - T7[-1] - a / dx^2.0 * (T8-2.0*T7+T6) * PERIOD

SLAB,,eqT8,?,3,T8 - T8[-1] - a / dx^2.0 * (T9-2.0*T8+T7) * PERIOD](https://image.slidesharecdn.com/pde-imf-141015202943-conversion-gate01/75/Partial-Differential-Equations-PDE-s-Industrial-Modeling-Framework-PDE-IMF-5-2048.jpg)

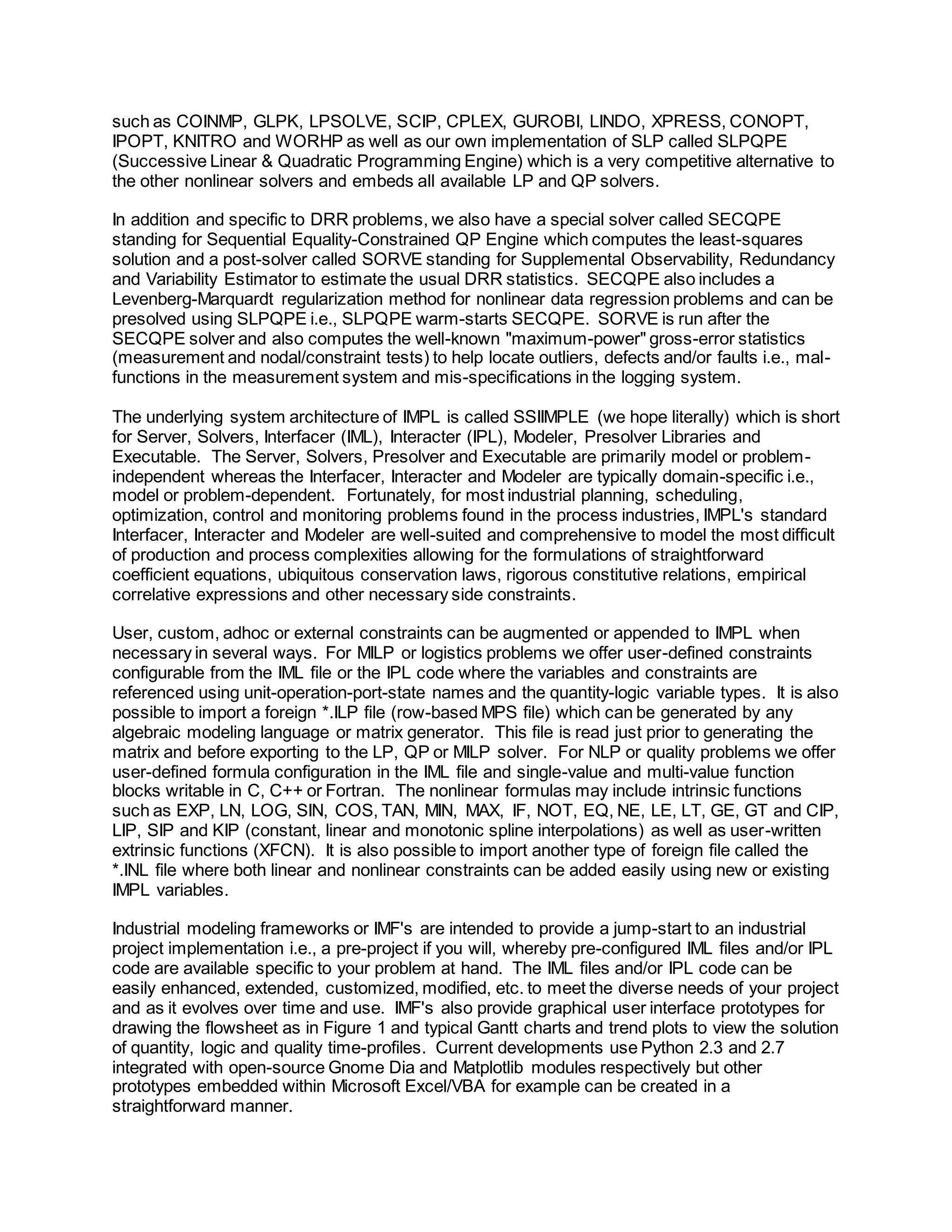

![SLAB,,eqT9,?,3,T9 - T9[-1] - a / dx^2.0 * (T10-2.0*T9+T8) * PERIOD

SLAB,,eqT10,?,3,T10 - T10[-1] - a / dx^2.0 * (T11-2.0*T10+T9) * PERIOD

SLAB,,T11,?,3,(4.0 * T10 - T9) / 3.0

ConditionsUOCondition-&sUnit,&sOperation,&sCondition,@sType,@rValue,@sValue

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Cost Data (Pricing)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

&sUnit,&sOperation,&sCondition,@rConditionPro_Weight,@rConditionPer1_Weight,@rConditionPer2_Weight,@rConditionPen_Weight

&sUnit,&sOperation,&sCondition,@rConditionPro_Weight,@rConditionPer1_Weight,@rConditionPer2_Weight,@rConditionPen_Weight

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Content Data (Past, Present Provisos)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

&sUnit,&sOperation,&sCondition,@rCondition_Value,@rStart_Time

SLAB,,T2,100.0,0.0

SLAB,,T3,100.0,0.0

SLAB,,T4,100.0,0.0

SLAB,,T5,100.0,0.0

SLAB,,T6,100.0,0.0

SLAB,,T7,100.0,0.0

SLAB,,T8,100.0,0.0

SLAB,,T9,100.0,0.0

SLAB,,T10,100.0,0.0

&sUnit,&sOperation,&sCondition,@rCondition_Value,@rStart_Time

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Command Data (Future Provisos)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

&sUnit,&sOperation,@rSetup_Lower,@rSetup_Upper,@rBegin_Time,@rEnd_Time

SLAB,,1,1,BEGIN,END

&sUnit,&sOperation,@rSetup_Lower,@rSetup_Upper,@rBegin_Time,@rEnd_Time

Appendix B – PDE-IMF-OC.IML File

i M P l (c)

Copyright and Property of i n d u s t r I A L g o r i t h m s LLC.

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Calculation Data (Parameters)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

&sCalc,@sValue

PERIOD,1.0

START,-PERIOD

BEGIN,0.0

END,6000.0

&sCalc,@sValue

XFCN-@sPath_Name,@sLibrary_Name,@sFunction_Name

C:IndustrialAlgorithmsProceduresx64Release,xfunc_ocl.dll,xfunc_ocl

XFCN-@sPath_Name,@sLibrary_Name,@sFunction_Name

&sCalc,@sValue

ALPHA,0.0

BETA,0.0

A11,XFCN(1;1;3;1;1;1;ALPHA;BETA)

A12,XFCN(1;2;3;1;1;1;ALPHA;BETA)

A13,XFCN(1;3;3;1;1;1;ALPHA;BETA)

A14,XFCN(1;4;3;1;1;1;ALPHA;BETA)

A15,XFCN(1;5;3;1;1;1;ALPHA;BETA)

A21,XFCN(2;1;3;1;1;1;ALPHA;BETA)

A22,XFCN(2;2;3;1;1;1;ALPHA;BETA)

A23,XFCN(2;3;3;1;1;1;ALPHA;BETA)

A24,XFCN(2;4;3;1;1;1;ALPHA;BETA)

A25,XFCN(2;5;3;1;1;1;ALPHA;BETA)

A31,XFCN(3;1;3;1;1;1;ALPHA;BETA)

A32,XFCN(3;2;3;1;1;1;ALPHA;BETA)

A33,XFCN(3;3;3;1;1;1;ALPHA;BETA)

A34,XFCN(3;4;3;1;1;1;ALPHA;BETA)

A35,XFCN(3;5;3;1;1;1;ALPHA;BETA)

A41,XFCN(4;1;3;1;1;1;ALPHA;BETA)

A42,XFCN(4;2;3;1;1;1;ALPHA;BETA)

A43,XFCN(4;3;3;1;1;1;ALPHA;BETA)

A44,XFCN(4;4;3;1;1;1;ALPHA;BETA)

A45,XFCN(4;5;3;1;1;1;ALPHA;BETA)

A51,XFCN(5;1;3;1;1;1;ALPHA;BETA)

A52,XFCN(5;2;3;1;1;1;ALPHA;BETA)

A53,XFCN(5;3;3;1;1;1;ALPHA;BETA)

A54,XFCN(5;4;3;1;1;1;ALPHA;BETA)

A55,XFCN(5;5;3;1;1;1;ALPHA;BETA)

B11,XFCN(1;1;3;1;1;2;ALPHA;BETA)

B12,XFCN(1;2;3;1;1;2;ALPHA;BETA)

B13,XFCN(1;3;3;1;1;2;ALPHA;BETA)

B14,XFCN(1;4;3;1;1;2;ALPHA;BETA)

B15,XFCN(1;5;3;1;1;2;ALPHA;BETA)

B21,XFCN(2;1;3;1;1;2;ALPHA;BETA)](https://image.slidesharecdn.com/pde-imf-141015202943-conversion-gate01/75/Partial-Differential-Equations-PDE-s-Industrial-Modeling-Framework-PDE-IMF-6-2048.jpg)

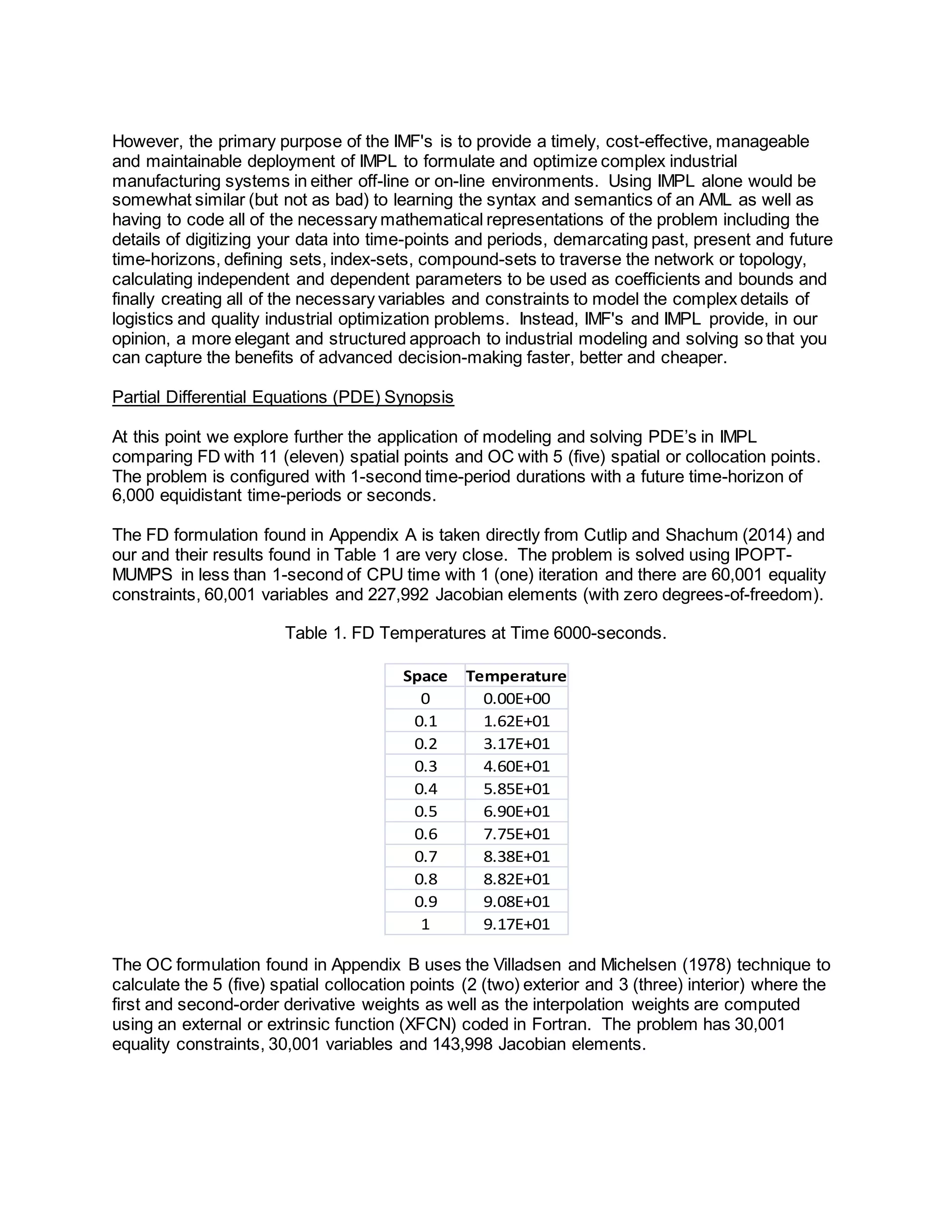

![B22,XFCN(2;2;3;1;1;2;ALPHA;BETA)

B23,XFCN(2;3;3;1;1;2;ALPHA;BETA)

B24,XFCN(2;4;3;1;1;2;ALPHA;BETA)

B25,XFCN(2;5;3;1;1;2;ALPHA;BETA)

B31,XFCN(3;1;3;1;1;2;ALPHA;BETA)

B32,XFCN(3;2;3;1;1;2;ALPHA;BETA)

B33,XFCN(3;3;3;1;1;2;ALPHA;BETA)

B34,XFCN(3;4;3;1;1;2;ALPHA;BETA)

B35,XFCN(3;5;3;1;1;2;ALPHA;BETA)

B41,XFCN(4;1;3;1;1;2;ALPHA;BETA)

B42,XFCN(4;2;3;1;1;2;ALPHA;BETA)

B43,XFCN(4;3;3;1;1;2;ALPHA;BETA)

B44,XFCN(4;4;3;1;1;2;ALPHA;BETA)

B45,XFCN(4;5;3;1;1;2;ALPHA;BETA)

B51,XFCN(5;1;3;1;1;2;ALPHA;BETA)

B52,XFCN(5;2;3;1;1;2;ALPHA;BETA)

B53,XFCN(5;3;3;1;1;2;ALPHA;BETA)

B54,XFCN(5;4;3;1;1;2;ALPHA;BETA)

B55,XFCN(5;5;3;1;1;2;ALPHA;BETA)

C1,XFCN(0.2;1;3;1;1;ALPHA;BETA)

C2,XFCN(0.2;2;3;1;1;ALPHA;BETA)

C3,XFCN(0.2;3;3;1;1;ALPHA;BETA)

C4,XFCN(0.2;4;3;1;1;ALPHA;BETA)

C5,XFCN(0.2;5;3;1;1;ALPHA;BETA)

&sCalc,@sValue

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Chronological Data (Periods)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

@rPastTHD,@rFutureTHD,@rTPD

START,END,PERIOD

@rPastTHD,@rFutureTHD,@rTPD

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Construction Data (Pointers)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

&sUnit,&sOperation,@sType,@sSubtype,@sUse

SLAB,,processc,blackbox,,

&sUnit,&sOperation,@sType,@sSubtype,@sUse

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Condition Data (Properties)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

&sCondition

T1

T2

T3

T4

T5

TX

eqT2

eqT3

eqT4

eqT5

eqTX

&sCondition

&sCoefficient,@sType,@sPath_Name,@sLibrary_Name,@sFunction_Name,@iNumber_Conditions,@rPerturb_Size,@sCondition_Names

a,static

&sCoefficient,@sType,@sPath_Name,@sLibrary_Name,@sFunction_Name,@iNumber_Conditions,@rPerturb_Size,@sCondition_Names

&sUnit,&sOperation,&sCondition,@rCondition_Lower,@rCondition_Upper,@rCondition_Target

SLAB,,T1,0.0,0.0,

SLAB,,T2,0.0,200.0,

SLAB,,T3,0.0,200.0,

SLAB,,T4,0.0,200.0,

SLAB,,T5,0.0,200.0,

SLAB,,TX,0.0,200.0,

SLAB,,eqT2,0.0,0.0,

SLAB,,eqT3,0.0,0.0,

SLAB,,eqT4,0.0,0.0,

SLAB,,eqT5,0.0,0.0,

&sUnit,&sOperation,&sCondition,@rCondition_Lower,@rCondition_Upper,@rCondition_Target

&sUnit,&sOperation,&sCoefficient,@rCoefficient_Lower,@rCoefficient_Upper,@rCoefficient_Target

SLAB,,a,2.0E-5,2.0E-5,

&sUnit,&sOperation,&sCoefficient,@rCoefficient_Lower,@rCoefficient_Upper,@rCoefficient_Target

ConditionsUOCondition-&sUnit,&sOperation,&sCondition,@sType,@rValue,@sValue

SLAB,,eqT2,?,3,T2 - T2[-1] - a * (B21*T1+B22*T2+B23*T3+B24*T4+B25*T5) * PERIOD

SLAB,,eqT3,?,3,T3 - T3[-1] - a * (B31*T1+B32*T2+B33*T3+B34*T4+B35*T5) * PERIOD

SLAB,,eqT4,?,3,T4 - T4[-1] - a * (B41*T1+B42*T2+B43*T3+B44*T4+B45*T5) * PERIOD

SLAB,,eqT5,?,3,(A51*T1+A52*T2+A53*T3+A54*T4+A55*T5)

SLAB,,TX,?,3,(C1*T1+C2*T2+C3*T3+C4*T4+C5*T5)

ConditionsUOCondition-&sUnit,&sOperation,&sCondition,@sType,@rValue,@sValue

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!

! Cost Data (Pricing)

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!](https://image.slidesharecdn.com/pde-imf-141015202943-conversion-gate01/75/Partial-Differential-Equations-PDE-s-Industrial-Modeling-Framework-PDE-IMF-7-2048.jpg)