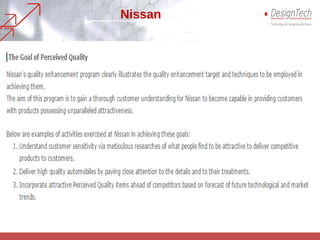

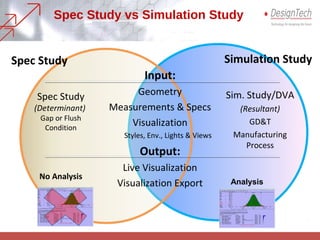

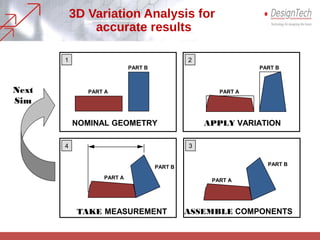

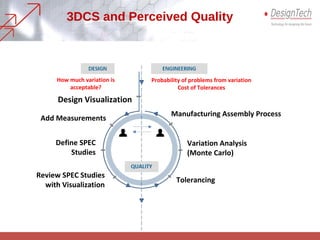

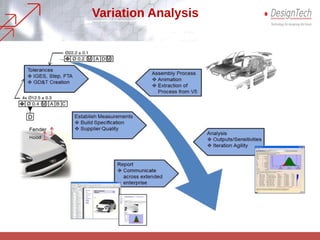

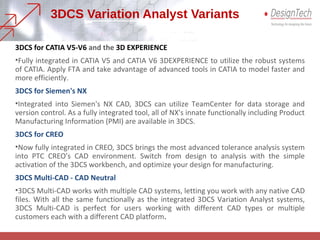

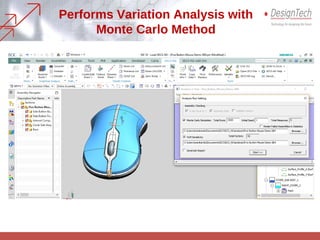

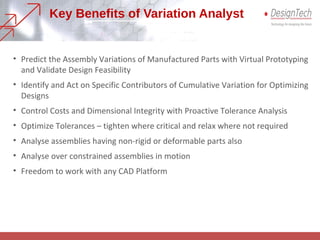

Designtech Systems Ltd. specializes in CAD/CAM/CAE, PLM, and 3D printing technologies, boasting over 19 years of experience and a presence in multiple countries. The company focuses on tolerance stack-up analysis using its 3DCS technology, which enhances product quality by optimizing design and manufacturing processes. With an extensive customer base that includes major automotive and aerospace manufacturers, Designtech aims to innovate and streamline product design methodologies.