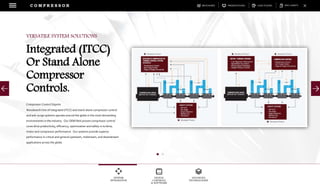

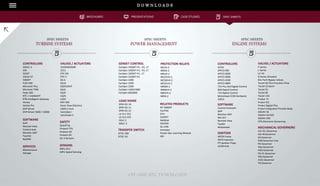

The document provides an update log and menu for an industrial solutions website. The update log notes that new presentations and brochures have been added and some existing information has been expanded. The main menu includes options for turbine systems, engine systems, power management, downloads, and website info. It provides submenus for steam turbines, gas turbines, safety systems, compressors, engines, power management products, and corporate channels.