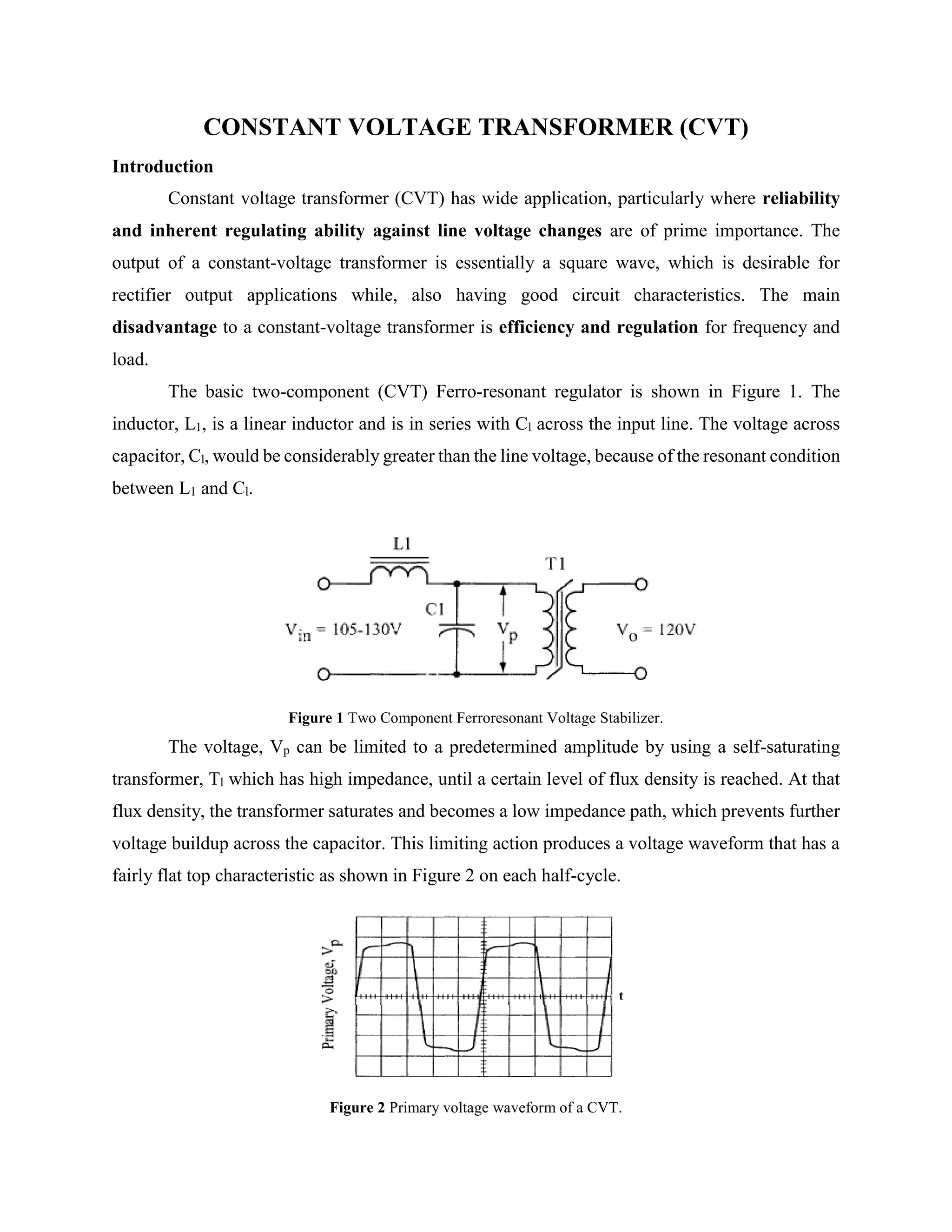

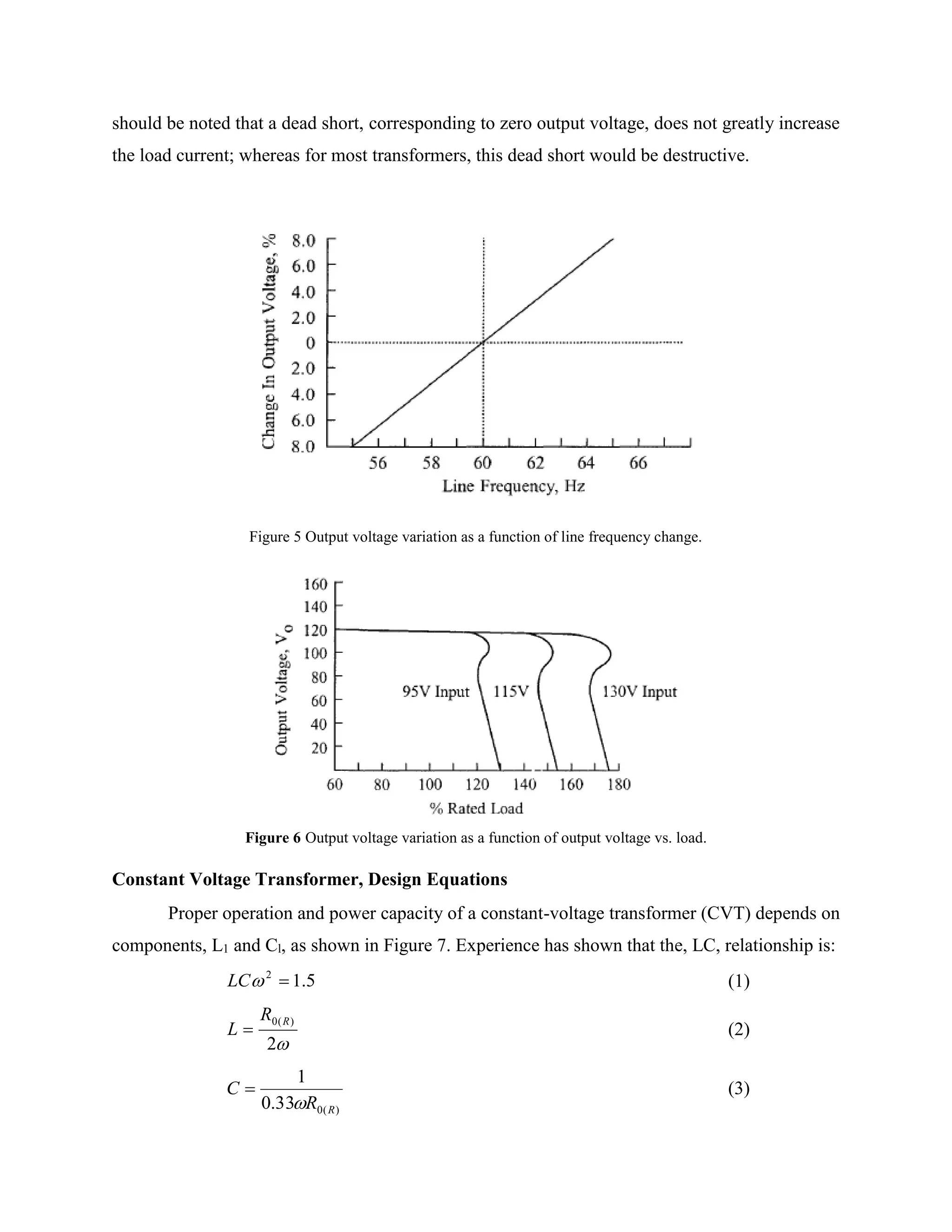

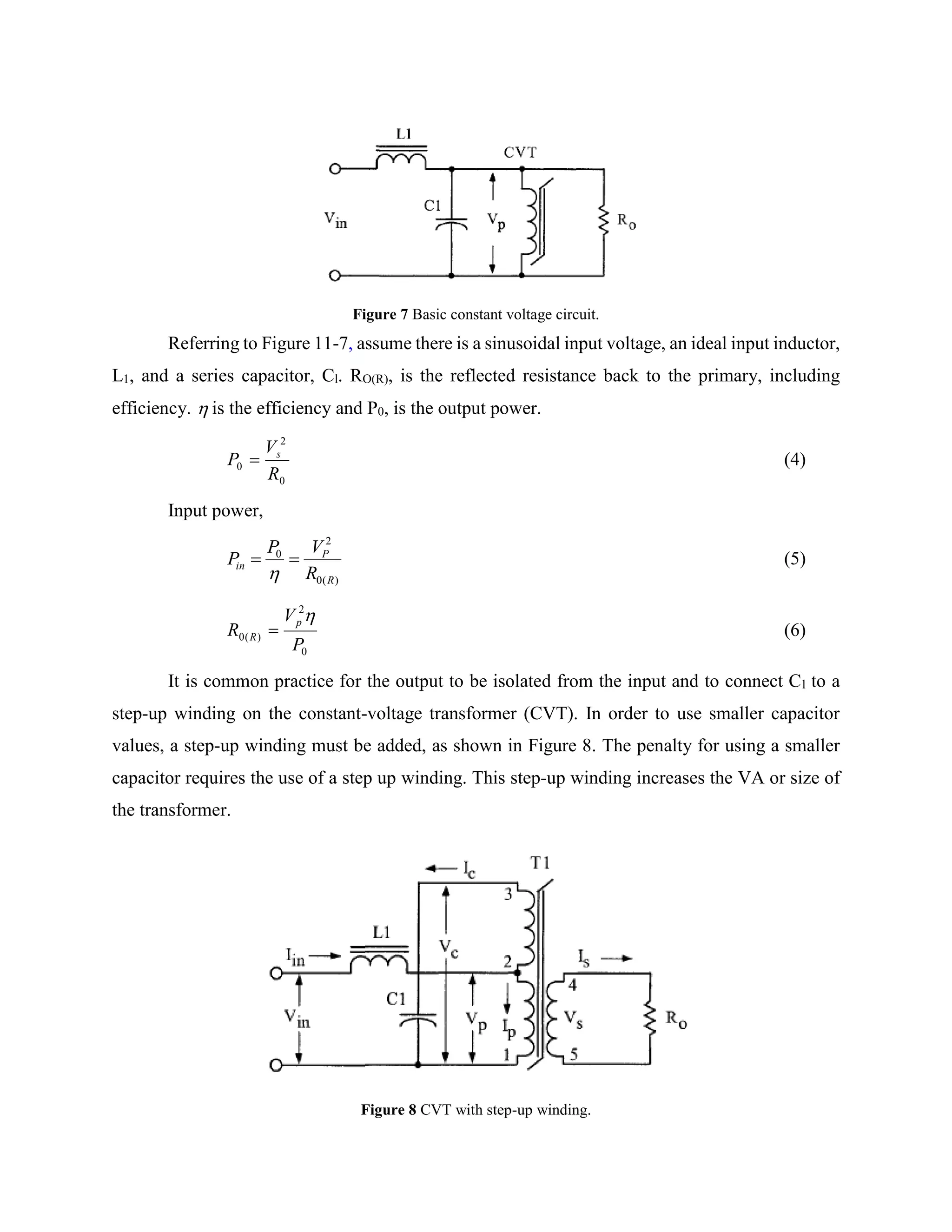

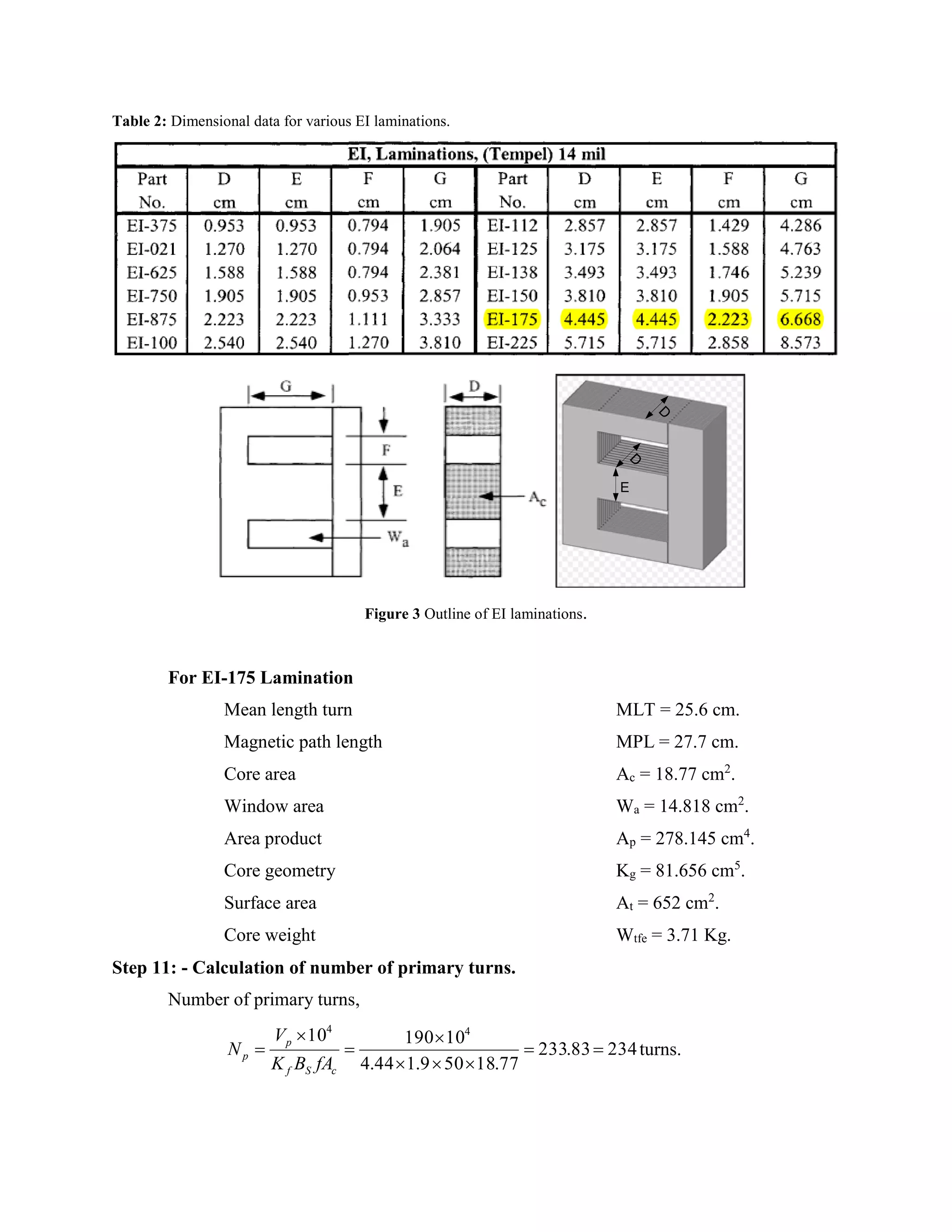

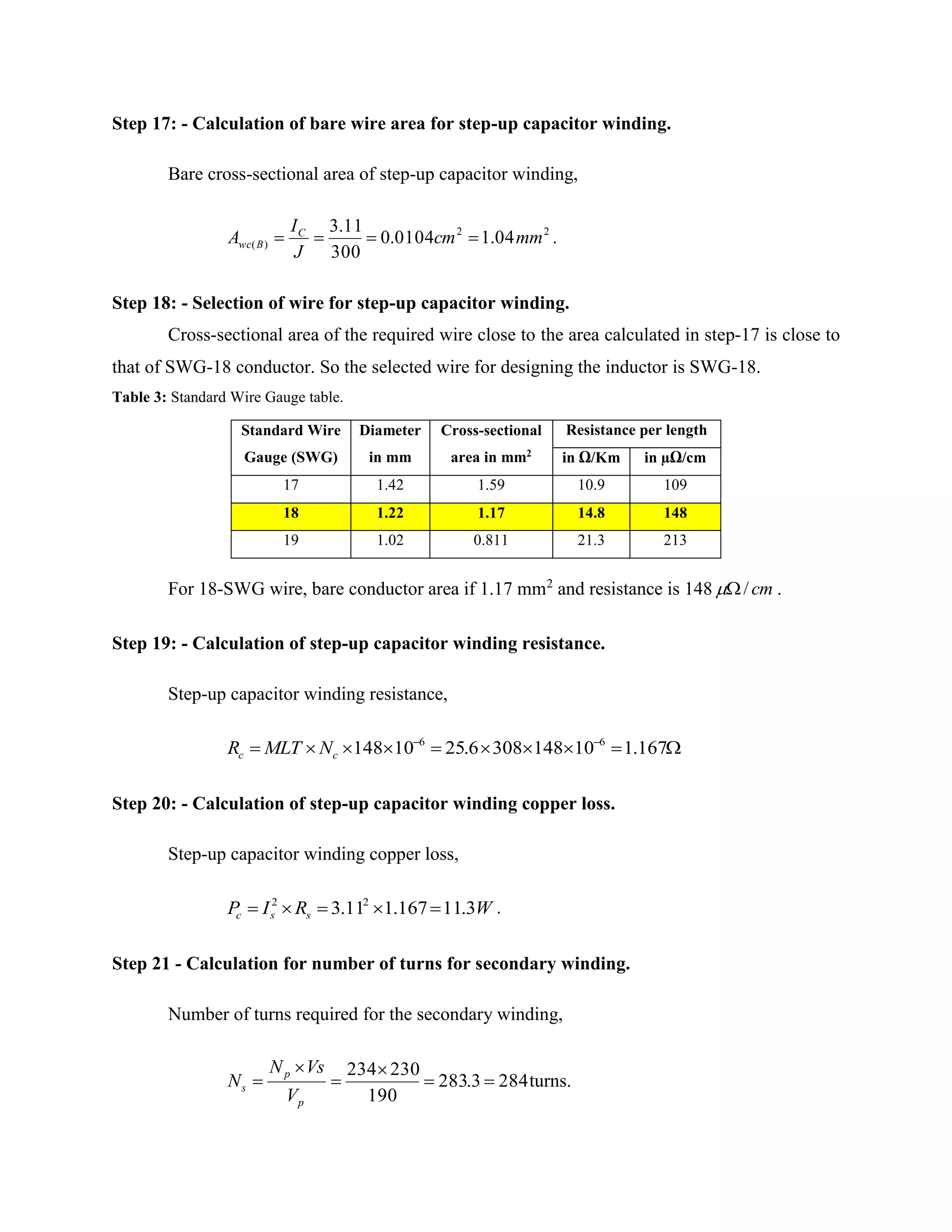

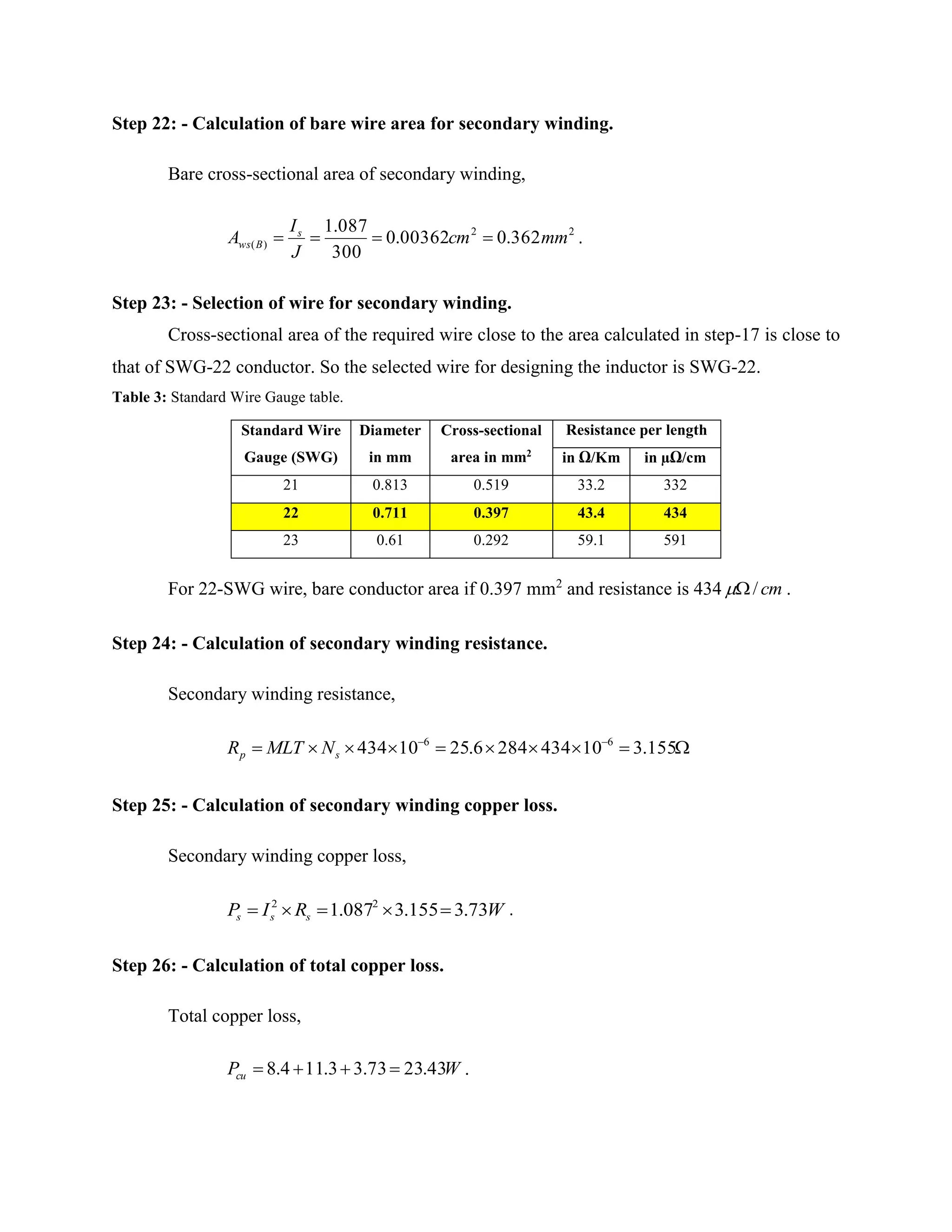

The document describes the components and operation of a constant voltage transformer (CVT). A CVT uses a ferroresonant circuit including an inductor, capacitor, and saturable transformer to regulate the output voltage against variations in input voltage, frequency, and load. It provides a constant output voltage through the saturating and limiting action of the saturable transformer. The output is a square wave suitable for rectifier applications. Design equations provided calculate component values, winding turns and sizes, losses, and other parameters for a CVT given specific voltage, power, and frequency specifications.