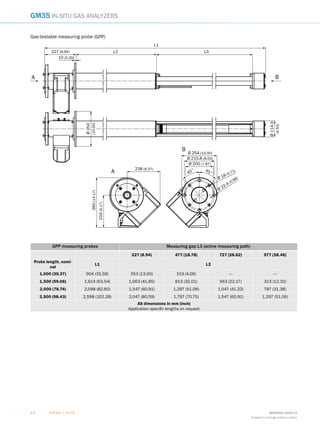

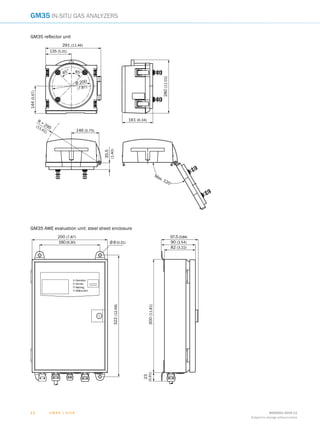

The GM35 in-situ gas analyzer from Sick is designed for simultaneous or individual measurement of CO2, H2O, CO, and N2O directly in gas-carrying ducts, enhancing efficiency in combustion and drying processes. Notable features include quick response times, minimal maintenance, and no need for complex gas sampling, making it suitable for monitoring greenhouse gas emissions in industrial applications. Various probe configurations allow for versatile installation in different system conditions, ensuring reliable and accurate measurements.