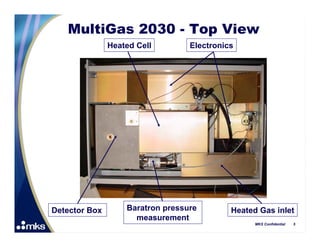

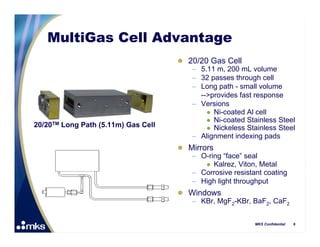

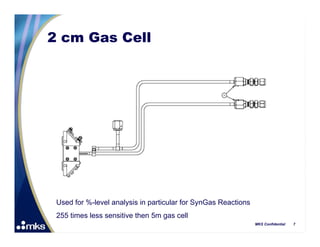

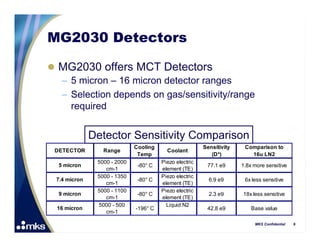

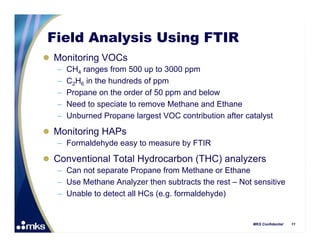

The document describes the MKS Instruments MultiGas 2030 FTIR gas analyzer. It has high resolution and fast response time of 1 second for analysis. It uses a long path length, small volume gas cell that provides fast response. It has various detector options including TE or LN2 cooled MCT detectors. The MultiGas 2030 maintains permanent calibration and can detect compounds at ppb to ppm levels simultaneously. It provides full instrument diagnostics and hardware components include a heated gas cell and electronics box. MKS Instruments provides support for applications of the MultiGas 2030 in areas like compliance monitoring, engineering, and ambient air analysis.