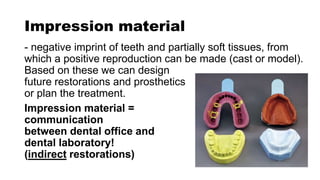

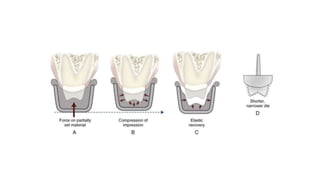

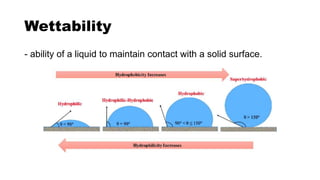

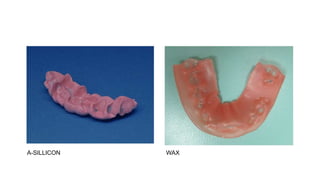

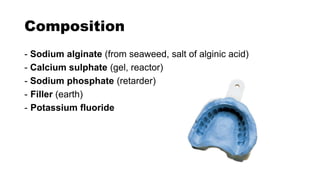

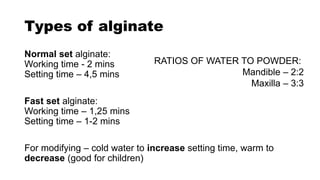

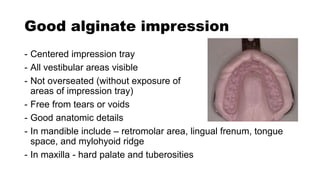

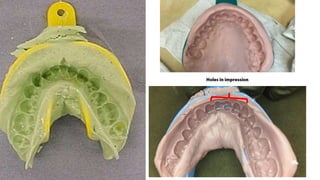

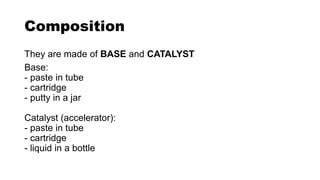

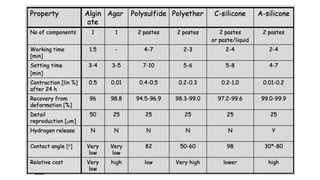

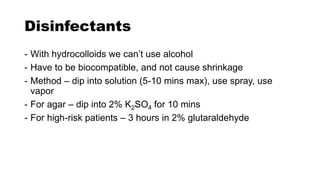

The document discusses impression materials used in dentistry, defining them as tools for creating negative imprints of teeth and soft tissues to produce positive reproductions for restorations and prosthetics. It details various types of impression materials, their applications, properties, and methods of use in diagnostic models, bite registration, and treatment planning across different dental disciplines. The importance of proper handling, dimensional stability, and compatibility with other materials is emphasized, along with the classification of the materials based on their characteristics and the specific techniques used for making impressions.