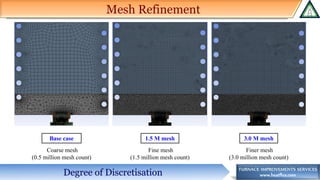

The document discusses the significance of mesh independence in CFD analysis of combustion systems, emphasizing the impact of domain discretization on results. It presents a study using three different mesh configurations, highlighting that increased refinement leads to more accurate representations of velocity distributions and flame patterns. The findings indicate that while refining the mesh enhances solution accuracy, it also doubles computation time.

![www.heatflux.com

[Min.]

[Max.]

Base case 1.5 M mesh 3.0 M mesh

Average throat velocity ~ 31 ft/s Average throat velocity ~ 23 ft/s Average throat velocity ~ 23 ft/s

Velocity Contours at Burner Throat

❖ Observations:

▪ Base case to 1.5 M case: Significant difference in the velocity distribution at burner throat and average throat velocity.

▪ 1.5 M to 3.0 M case: Almost similar velocity distribution at burner throat.

❖ Conclusion:

▪ Base case (coarse mesh) does not give an ideal depiction of throat velocity distribution. Mesh refinement gives more accurate

distribution. An accurate throat velocity distribution will give an accurate flame pattern.

CFD Result: Velocity Distribution](https://image.slidesharecdn.com/importanceofmeshindependencestudy-180316045647/85/Importance-of-mesh-independence-study-5-320.jpg)

![www.heatflux.com

[Min.]

[Max.]

Flue Gas Velocity Contours

❖ As the mesh refinement is increased, the

flow from primary and staged tips become

more distinguished.

❖ Base case shows a combined flow pattern

which indicates that the flame would be from

a combined flow of tips.

❖ Velocity pattern for the other two cases show

that there will be lobes of staged fuel and a

central flame region due to primary fuel.

CFD Result: Velocity Distribution

Base case 1.5 M mesh 3.0 M mesh](https://image.slidesharecdn.com/importanceofmeshindependencestudy-180316045647/85/Importance-of-mesh-independence-study-6-320.jpg)

![www.heatflux.com

[Min.]

[Max.]

Flue Gas Velocity Contours

❖ Significant difference in the velocity profile

in the heater with a change in mesh

resolution.

❖ Ideal profile: Higher velocity at the center

with recirculated flow near the tubes and

walls

▪ This is obtained in 3.0 M mesh case.

▪ 1.5 M mesh case has flow tilted in one direction

▪ Base case has flow tilted towards the unshielded wall

CFD Result: Velocity Distribution

Base case 1.5 M mesh 3.0 M mesh](https://image.slidesharecdn.com/importanceofmeshindependencestudy-180316045647/85/Importance-of-mesh-independence-study-7-320.jpg)

![www.heatflux.com

Large recirculation on

one side

[Min.]

[Max.]

Flue Gas Velocity Vectors

❖ The density of vector in the images is

indicative of the mesh resolution.

❖ 3.0 M mesh case shows the best recirculation

pattern along with a more accurate depiction

of gas mixing from burner.

CFD Result: Velocity Flow Profile

Base case 1.5 M mesh 3.0 M mesh](https://image.slidesharecdn.com/importanceofmeshindependencestudy-180316045647/85/Importance-of-mesh-independence-study-8-320.jpg)

![www.heatflux.com

[Min.]

[Max.]

Flue Gas Temperature Contours

❖ Significant difference in the temperature

profile in the heater with a change in mesh

resolution.

❖ High flue gas temperature is observed near

the tubes in the first two cases (highlighted

regions)

CFD Result: Temperature Distribution

Base case 1.5 M mesh 3.0 M mesh](https://image.slidesharecdn.com/importanceofmeshindependencestudy-180316045647/85/Importance-of-mesh-independence-study-9-320.jpg)

![www.heatflux.com

Flame Height:

5.7 ft

(Based on an iso-

surface of CO)

Flame Height:

6.0 ft

Flame Height:

7.2 ft

[Min.]

[Max.]

Flame Height

❖ Large difference in the flame pattern

observed in the three cases

❖ Cases 2 and 3 with more refined meshes

indicate formation of lobes of the flame iso-

surface.

CFD Result: Flame Profile

Base case 1.5 M mesh 3.0 M mesh](https://image.slidesharecdn.com/importanceofmeshindependencestudy-180316045647/85/Importance-of-mesh-independence-study-10-320.jpg)

![www.heatflux.com

[Min.]

[Max.]

Radiant Tube Temperature Profile

❖ Mesh refinement has little impact on the

temperature pattern. However, most refined

mesh (3.0 M) indicates a value lower by 8 ºF.

❖ Slight difference in the temperature pattern is

observed on the highlighted tubes

CFD Result: Heat Distribution on Tubes

Base case 1.5 M mesh 3.0 M mesh](https://image.slidesharecdn.com/importanceofmeshindependencestudy-180316045647/85/Importance-of-mesh-independence-study-11-320.jpg)