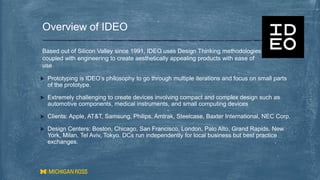

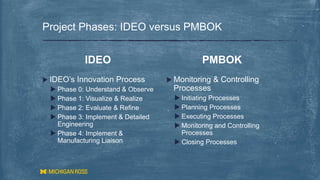

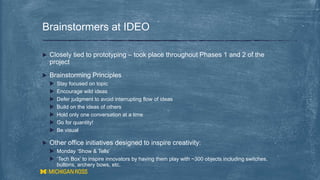

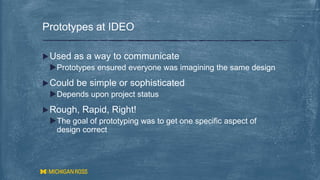

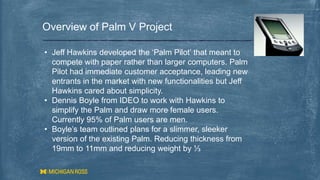

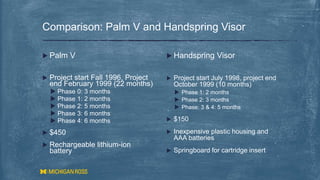

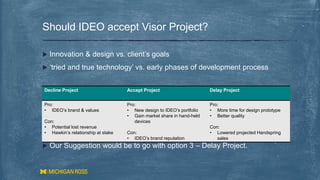

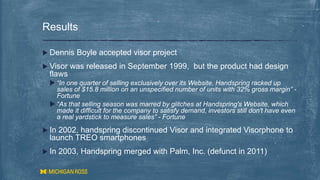

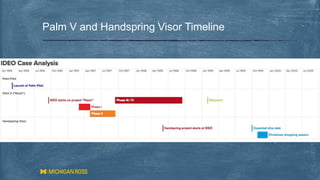

IDEO uses design thinking methodology and prototyping to create user-friendly products. It helped develop the Palm Pilot and later the slimmer Palm V. When asked to work on the Handspring Visor, a proposed competitor, IDEO initially considered declining due to brand issues but ultimately accepted and launched the Visor in 1999, though it had design flaws. This case examines IDEO's process versus traditional project management and differences between the Palm V and Visor projects.