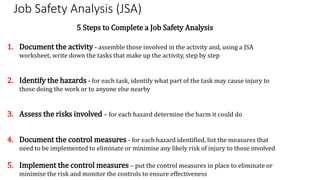

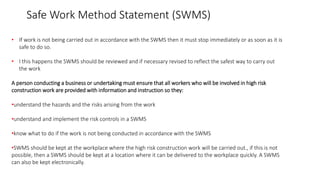

The document discusses preparing job safety analyses (JSAs) and safe work method statements (SWMS) for construction work. It outlines that JSAs are used to identify general hazards, while SWMS are required by law for high-risk construction work. The key steps to complete a JSA and SWMS are described, including identifying hazards, assessing risks, and documenting control measures. Relevant legislation, standards, and codes of practice are also summarized.