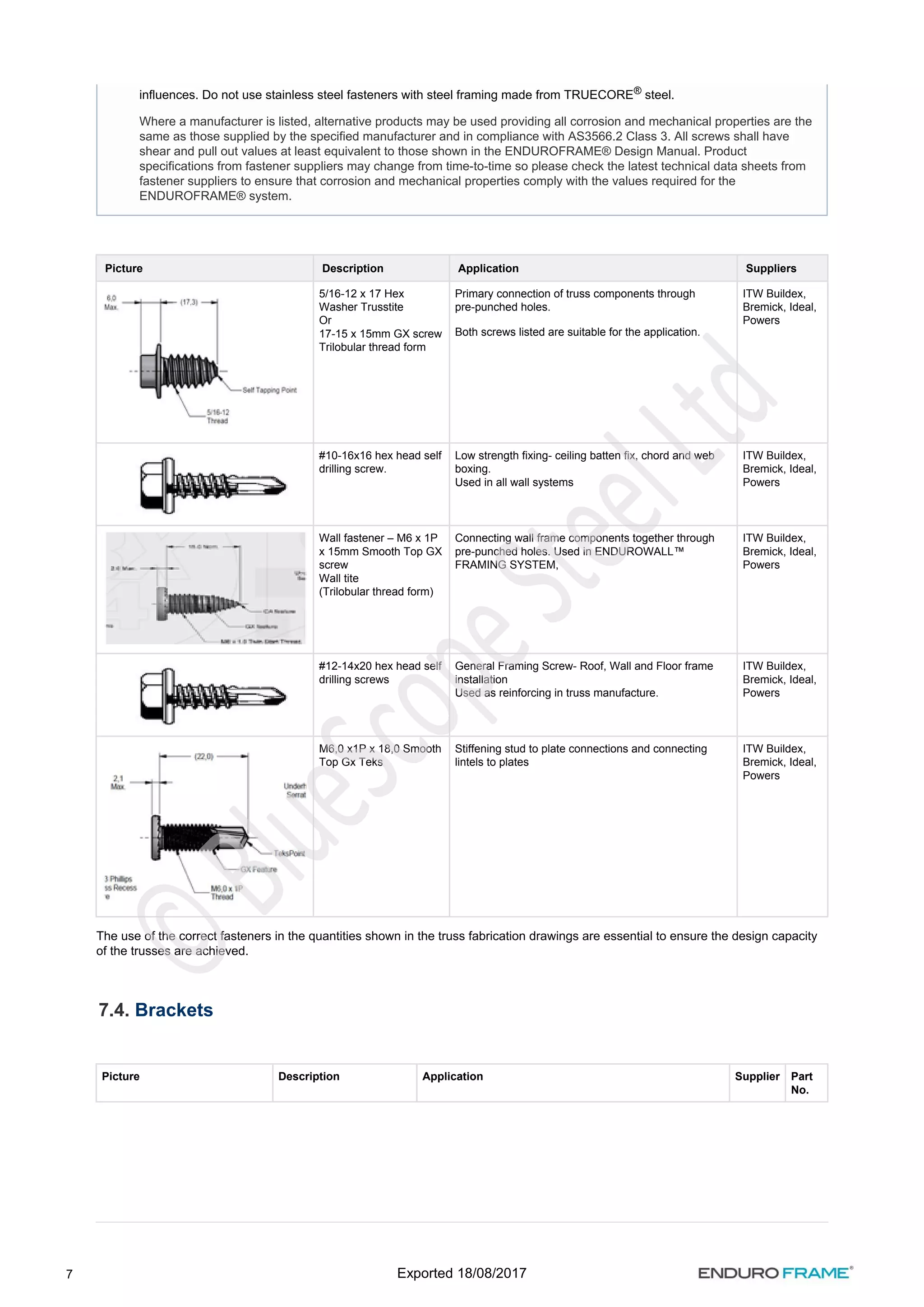

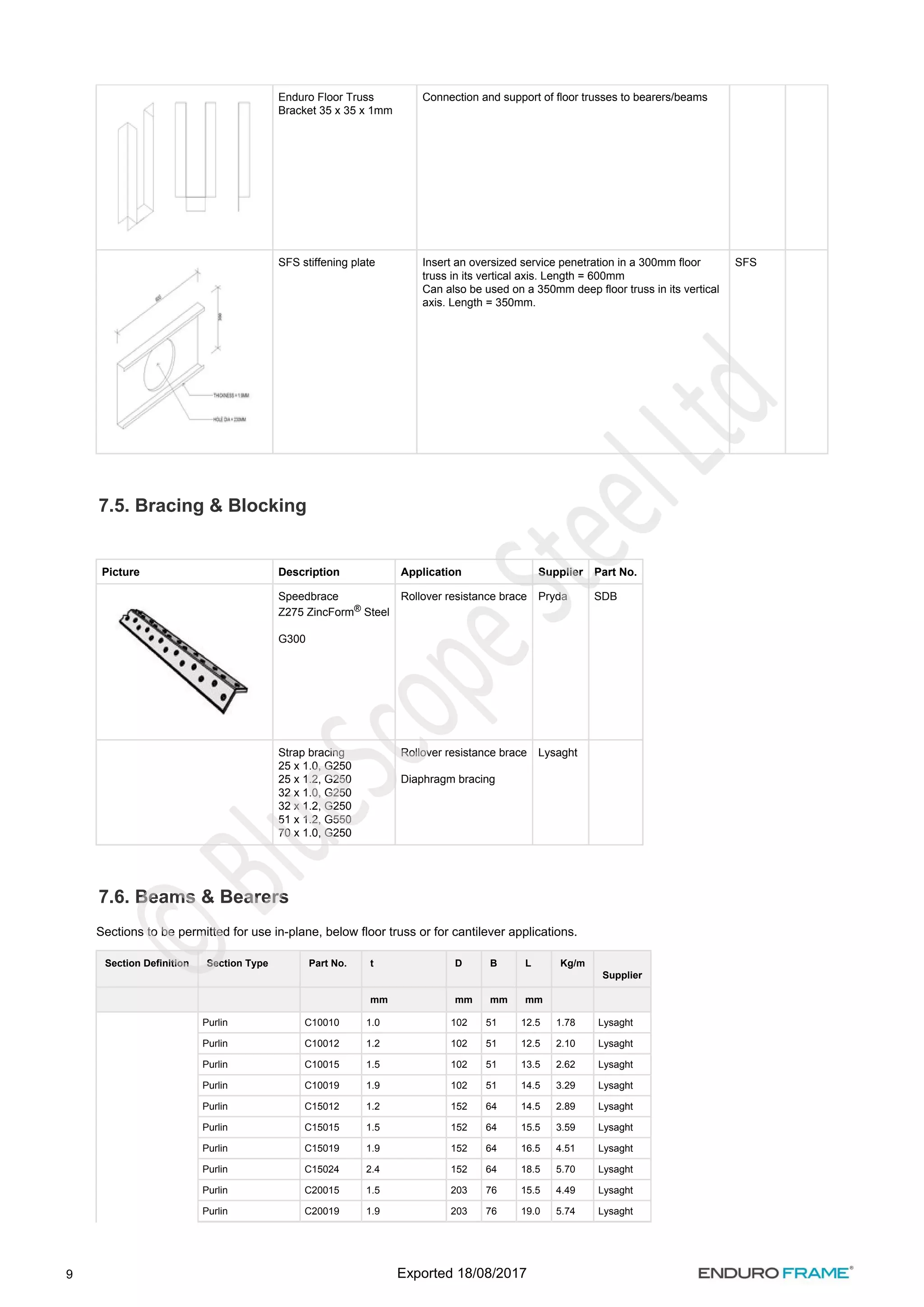

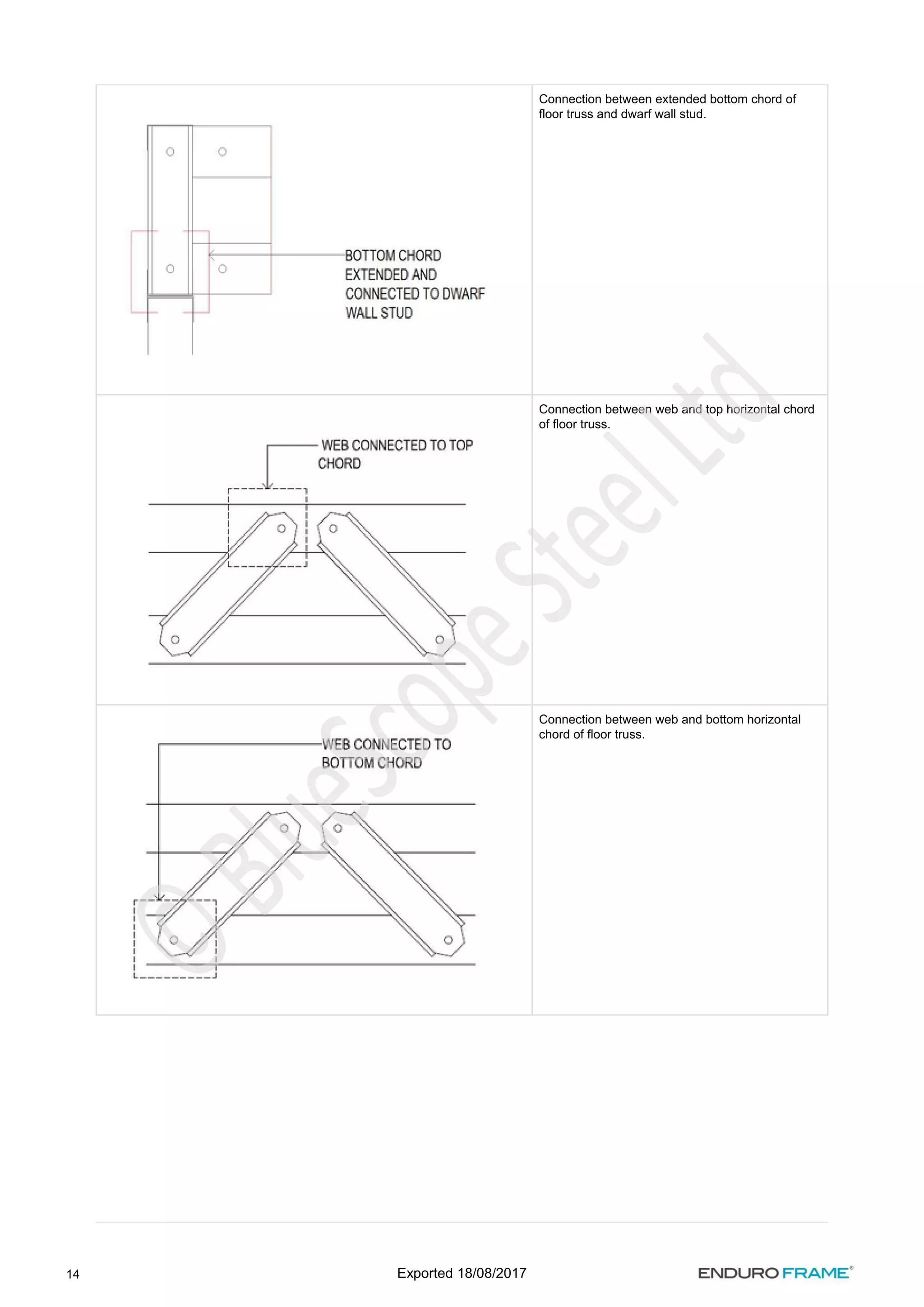

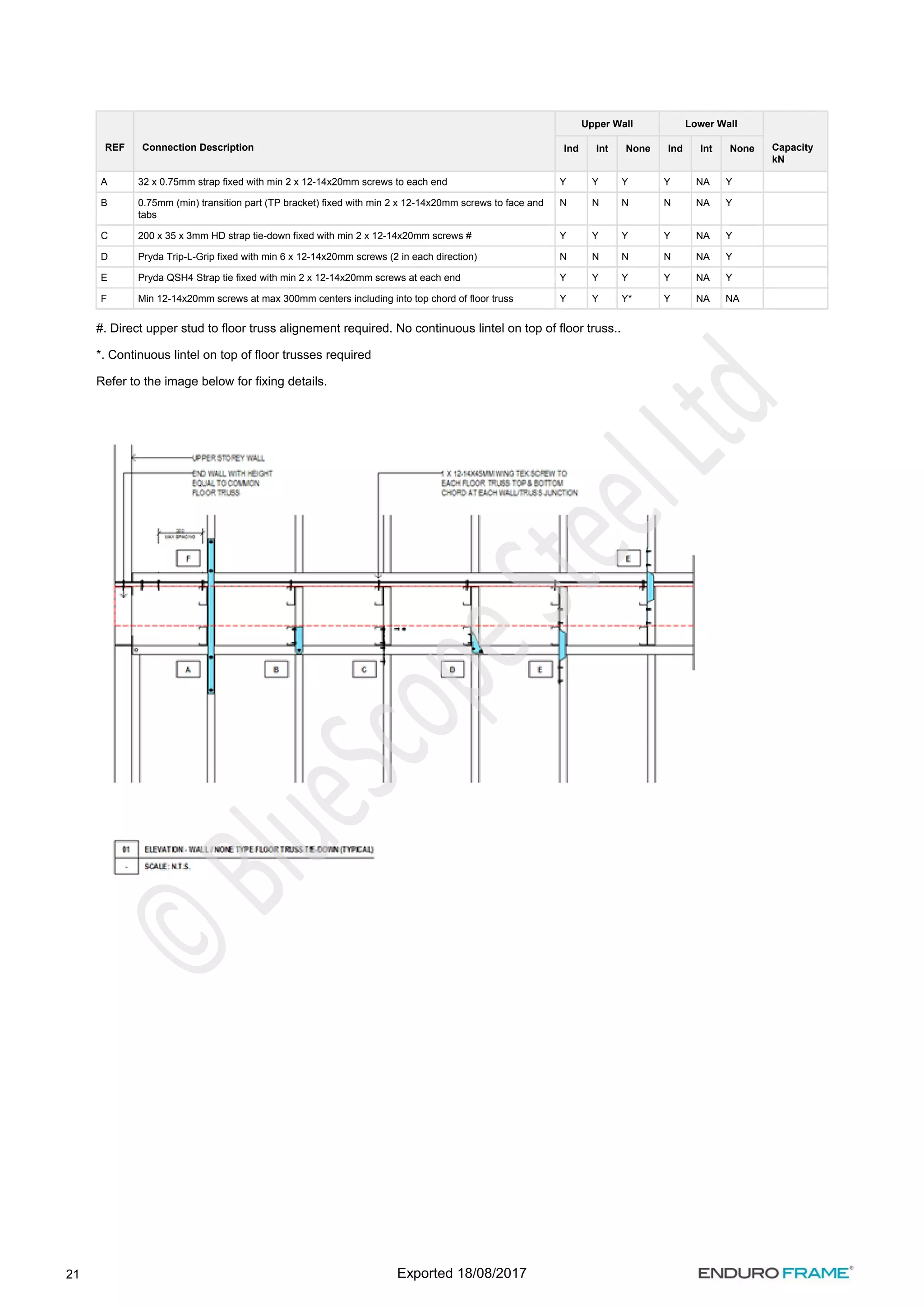

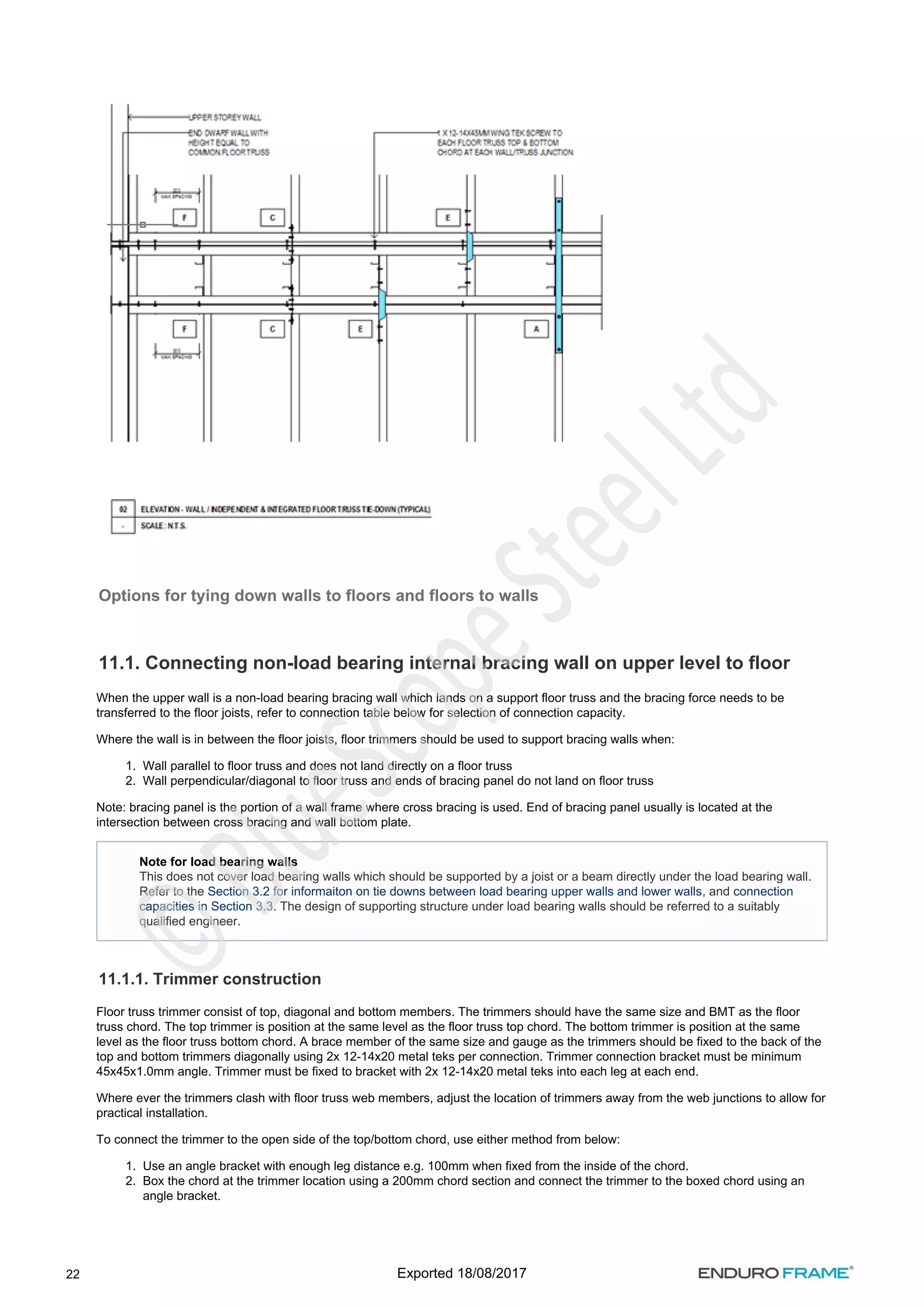

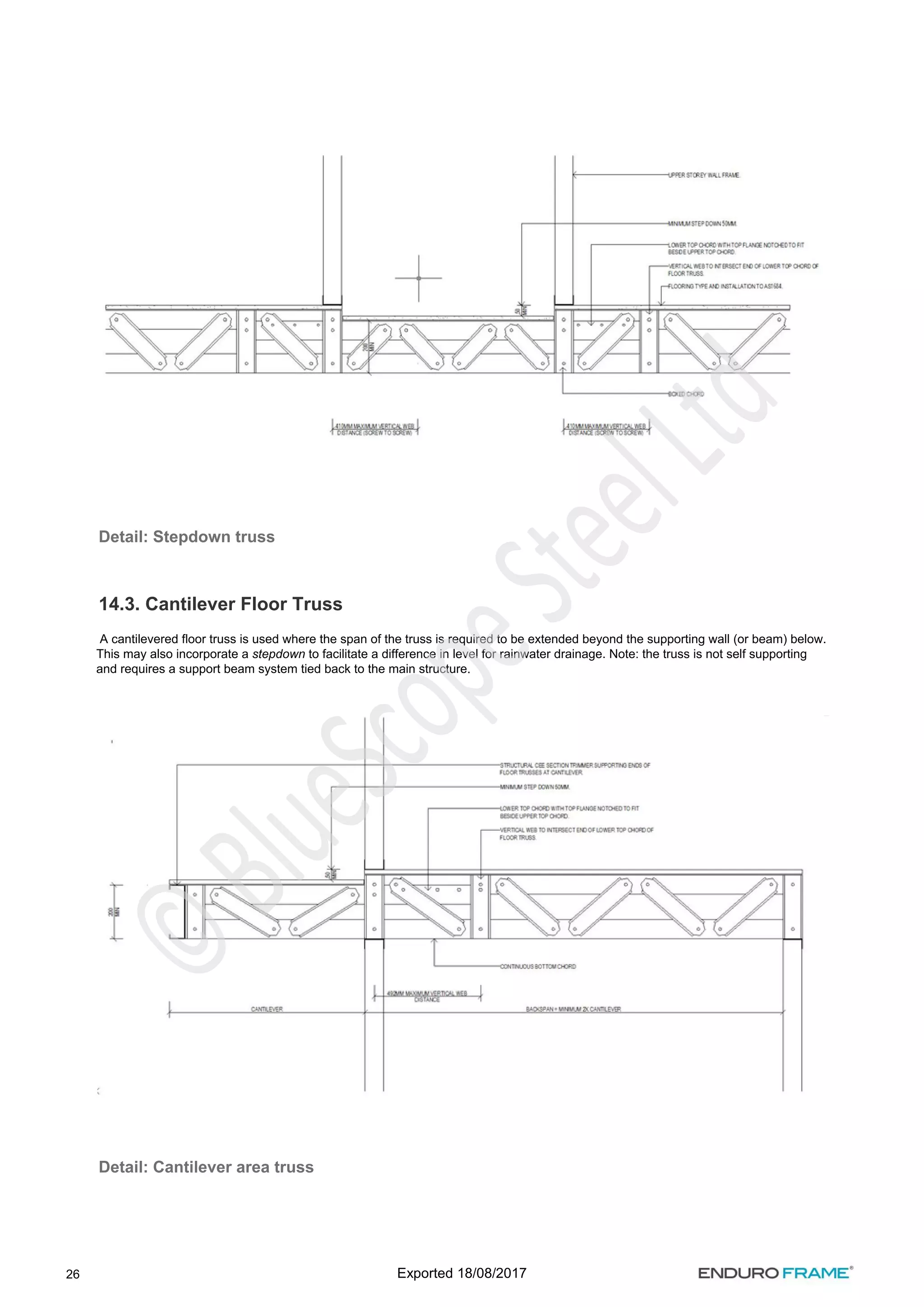

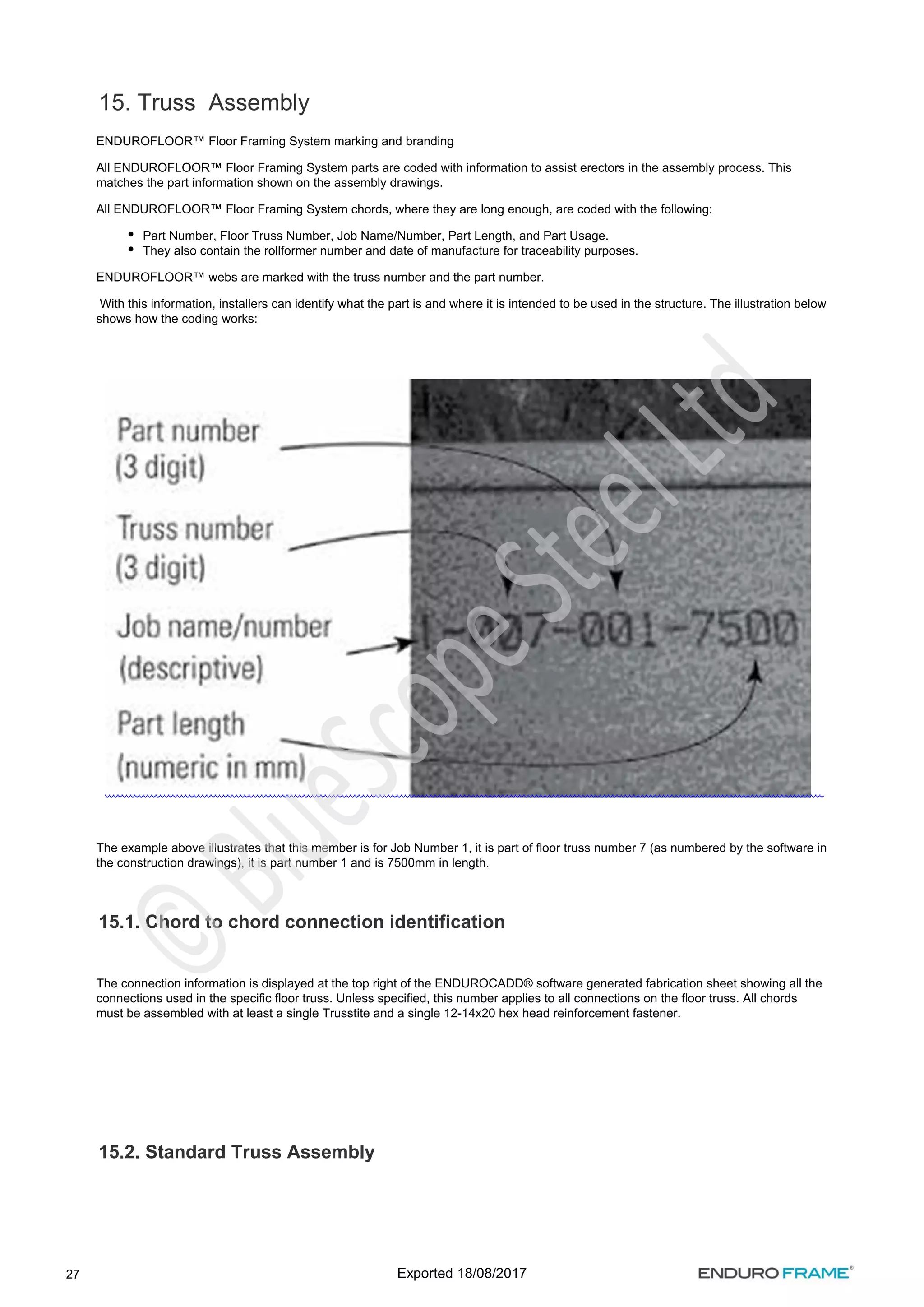

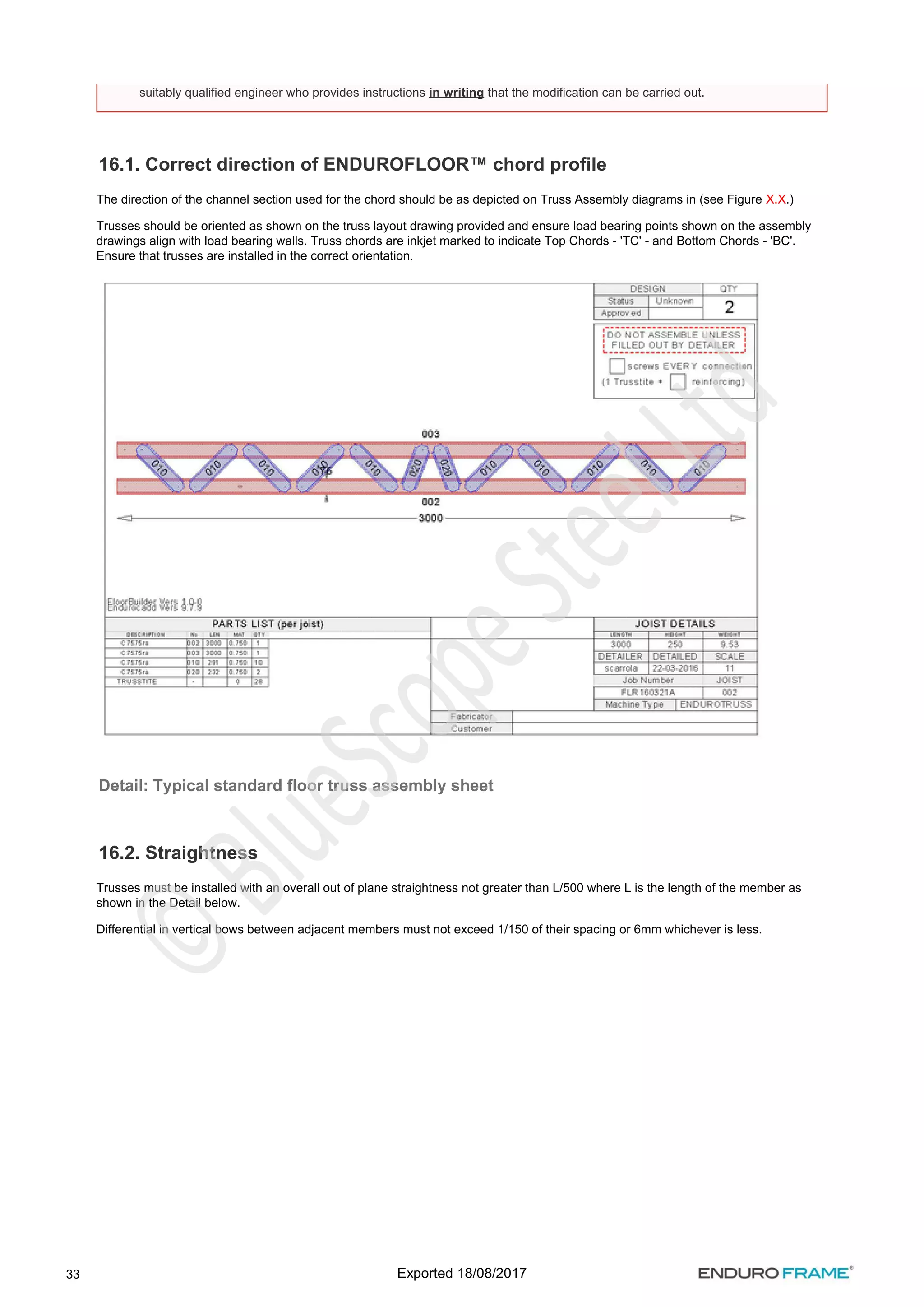

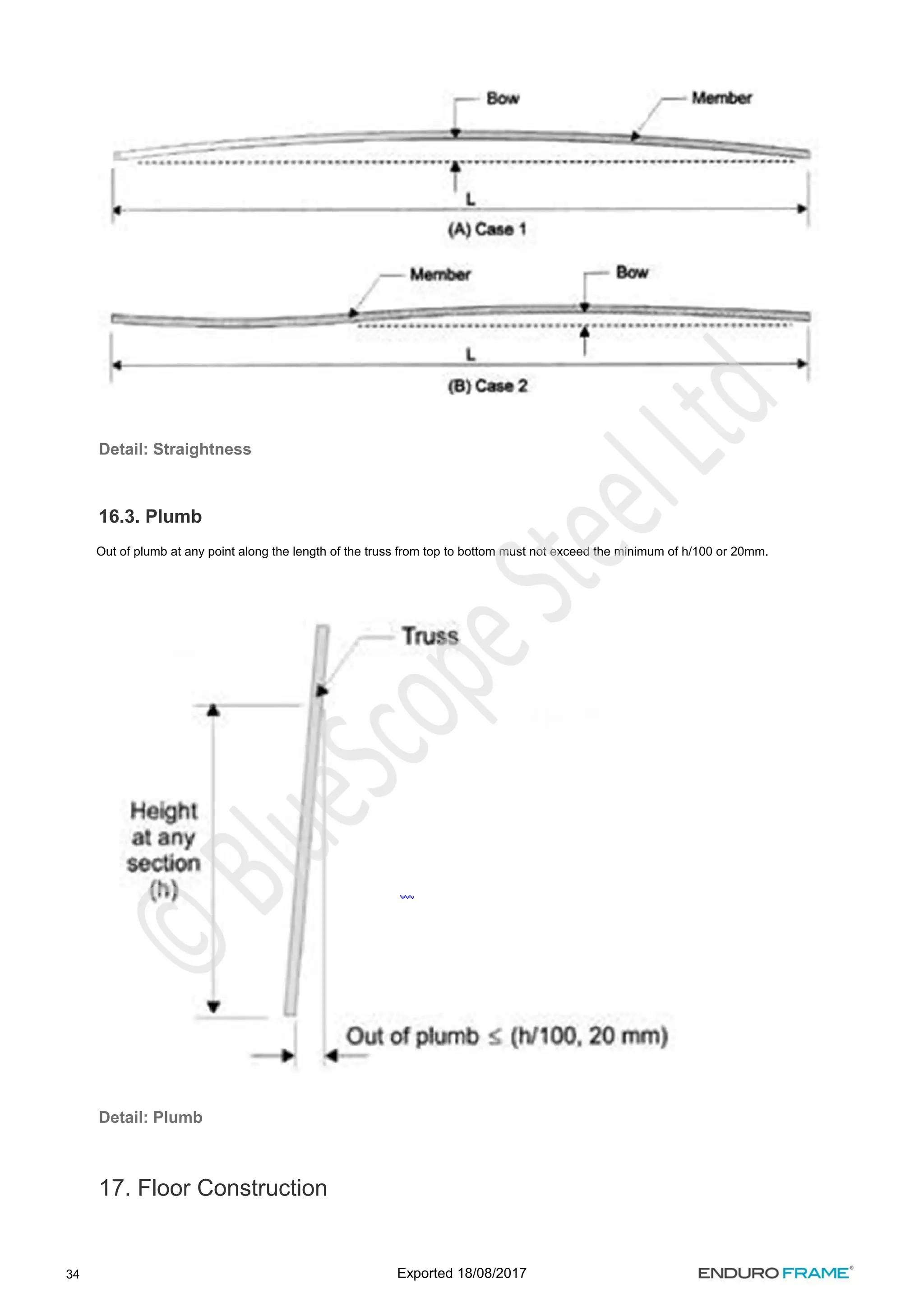

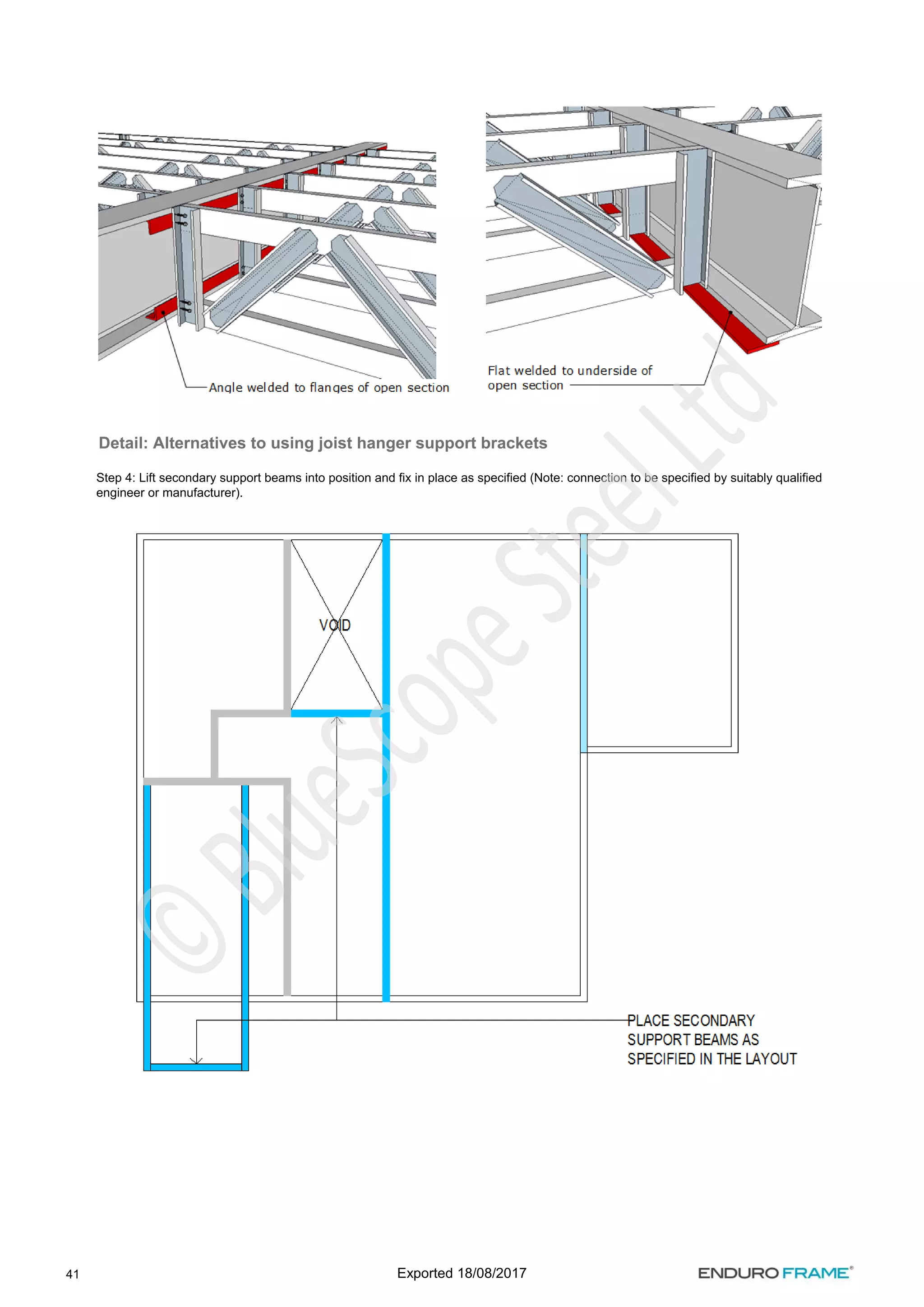

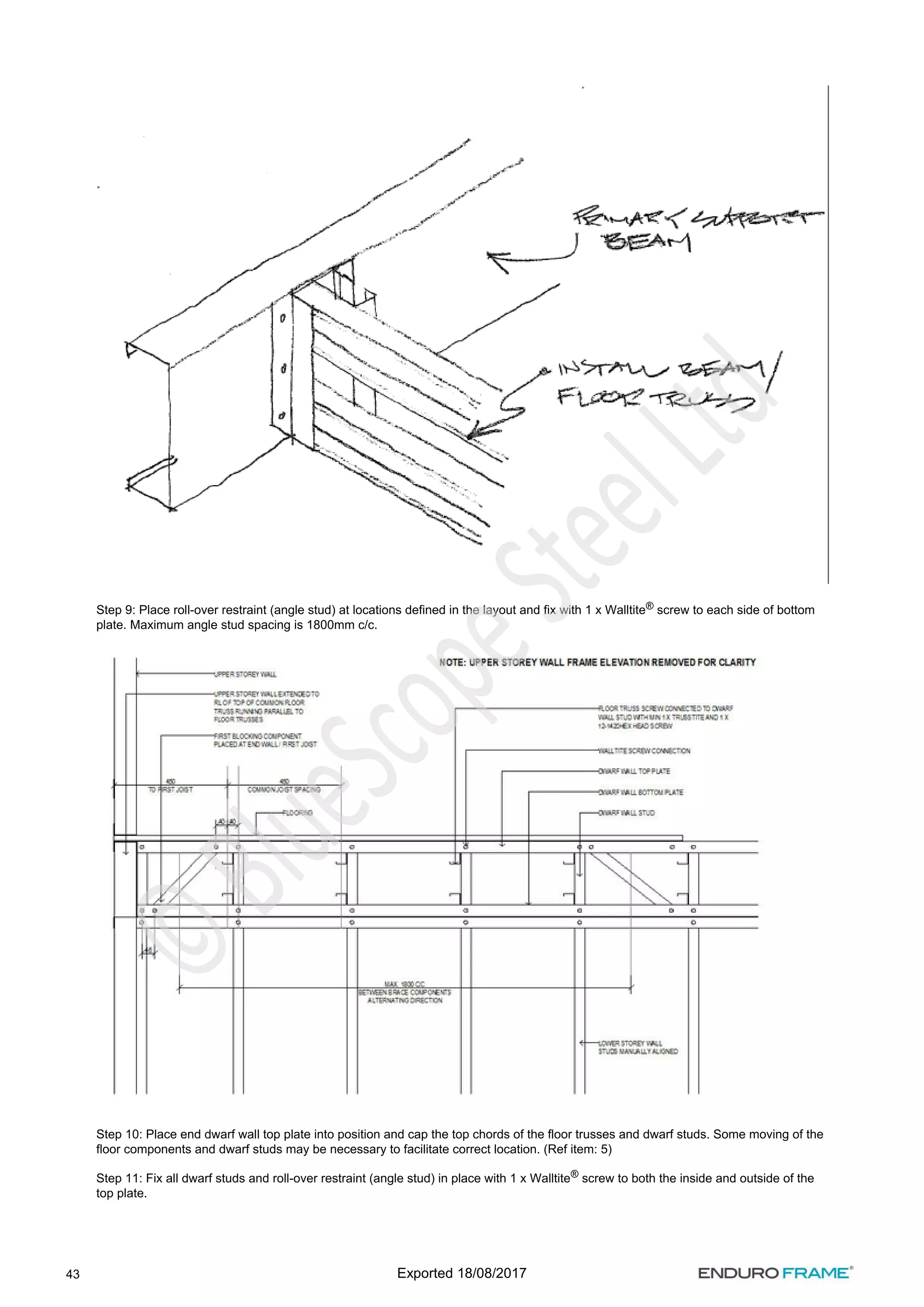

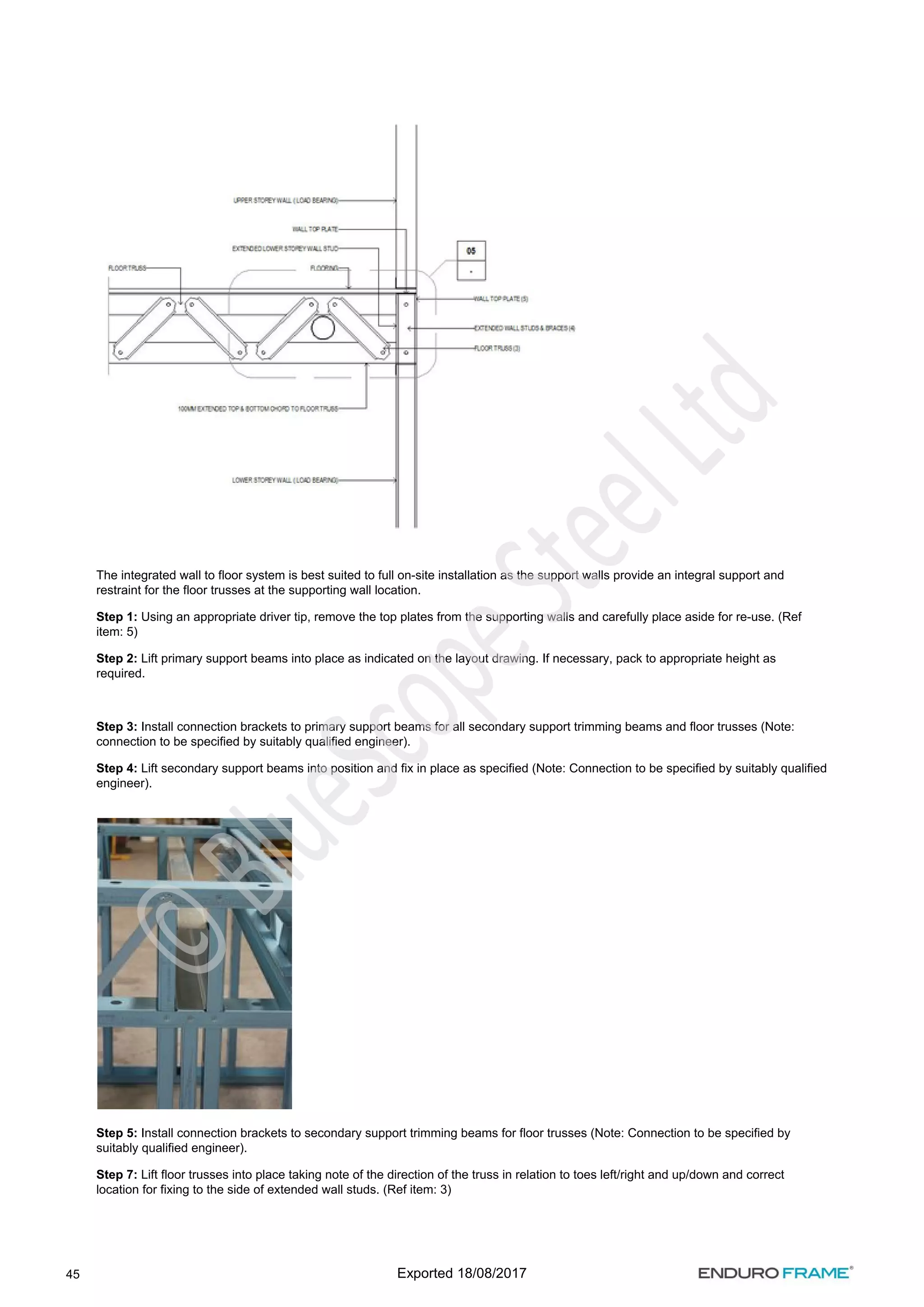

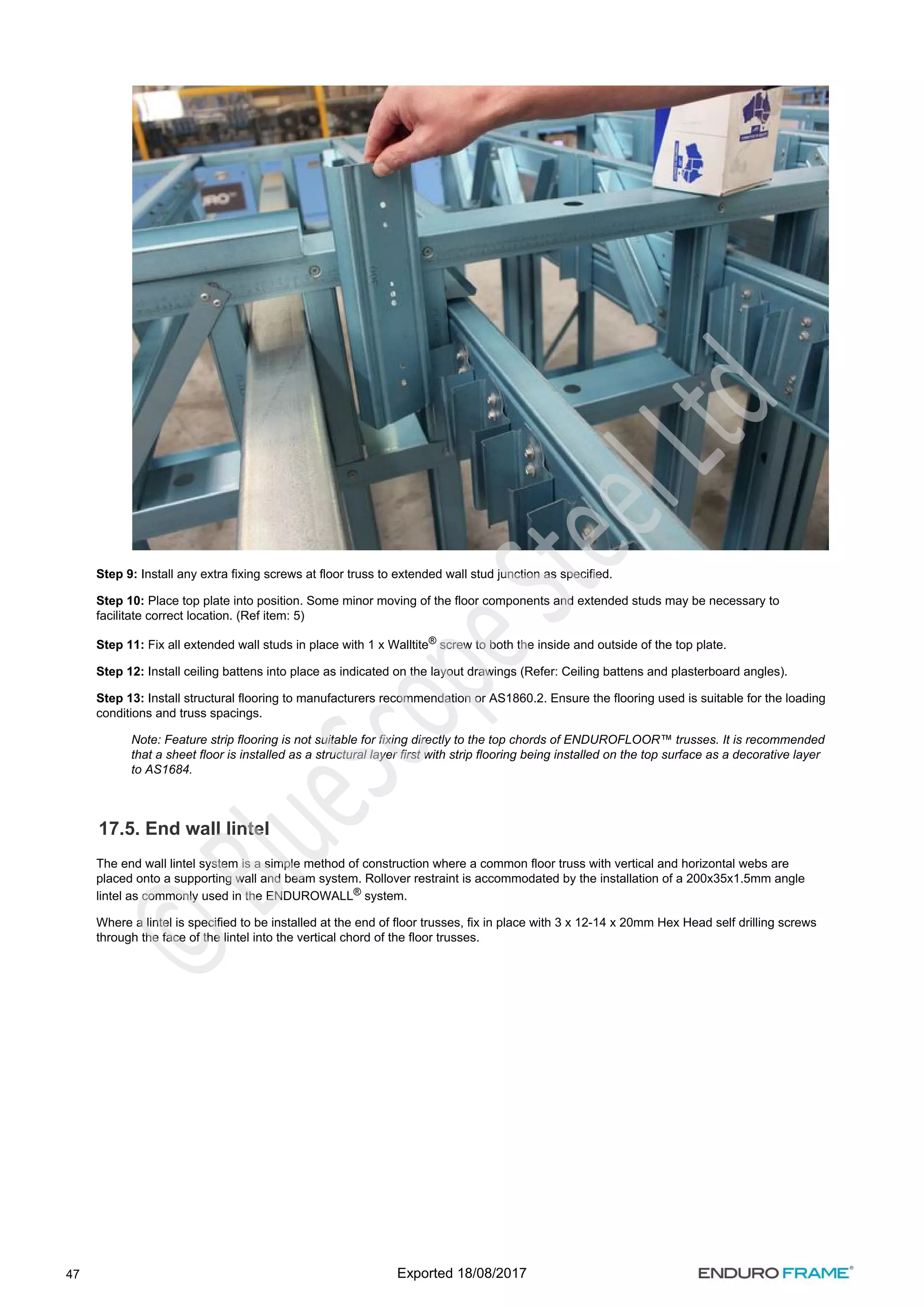

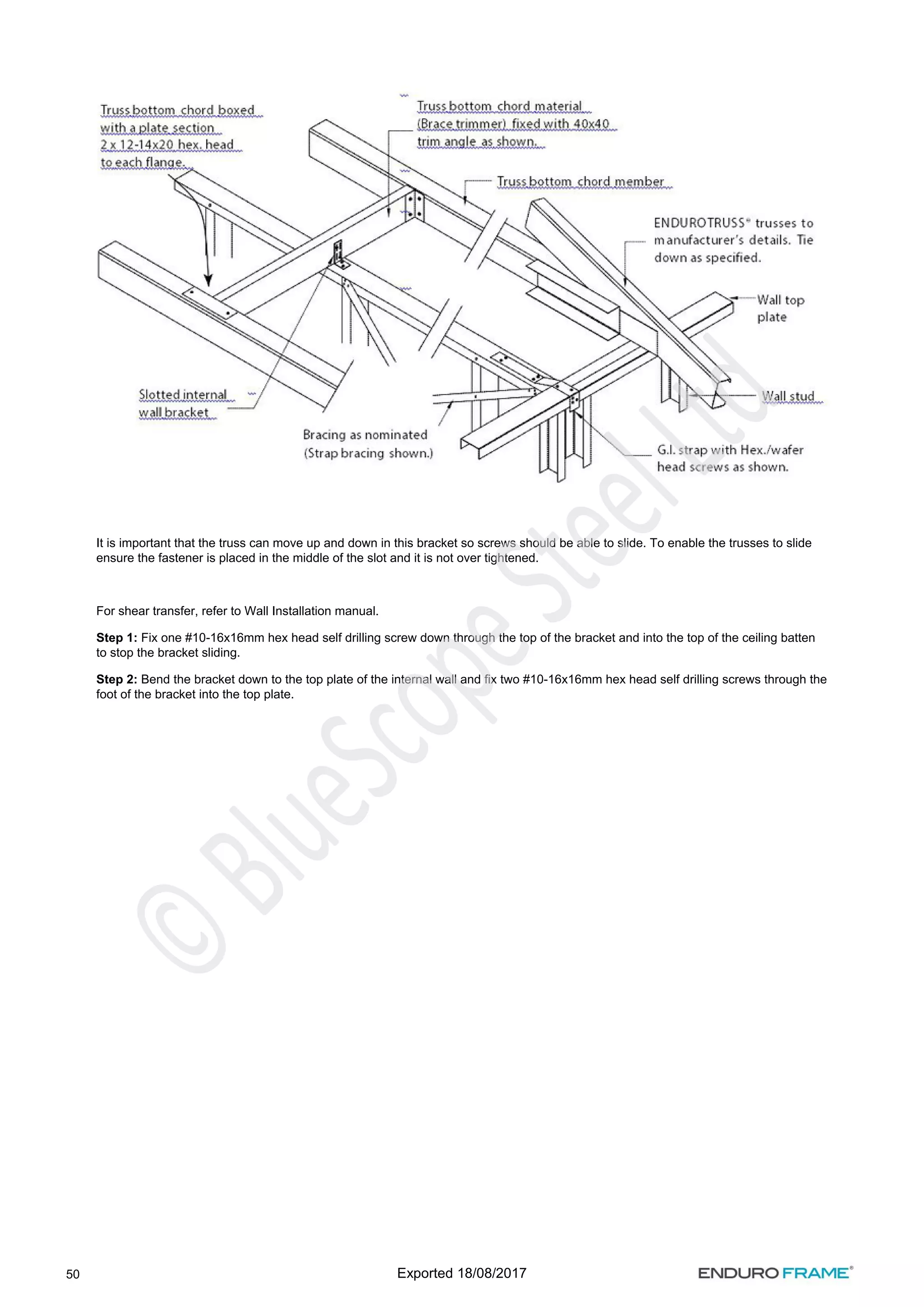

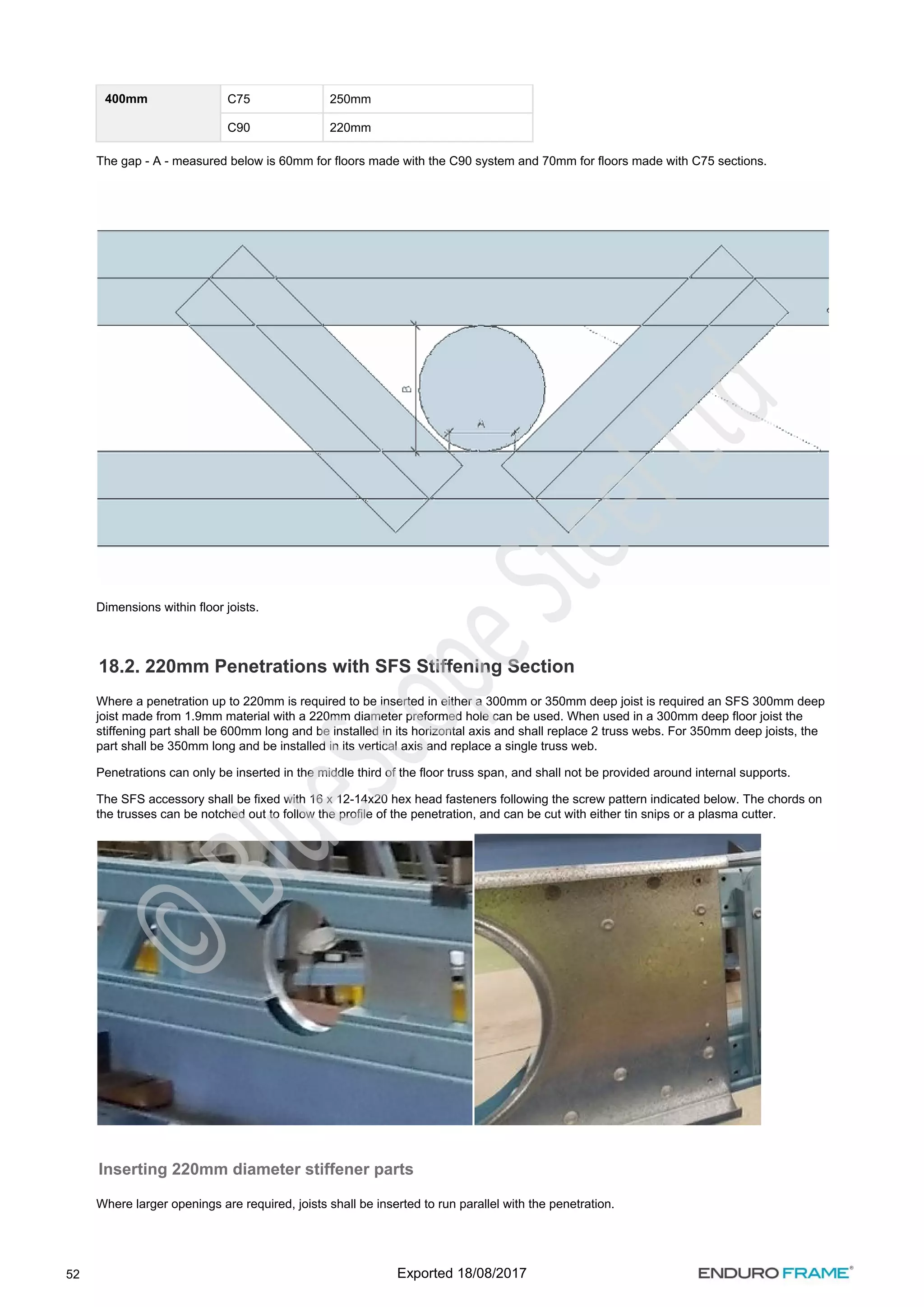

This document provides an installation manual for the ENDUROFLOORTM Floor System. It outlines the product specifications, design considerations, required tools and safety equipment, framing components, and step-by-step installation instructions. The manual is intended to guide installation of steel-framed floors using ENDUROFLOORTM components in accordance with design specifications and relevant safety standards.