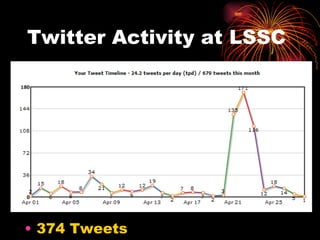

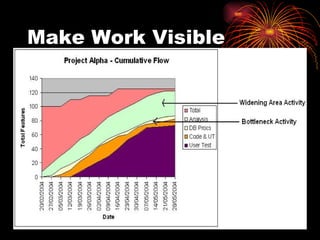

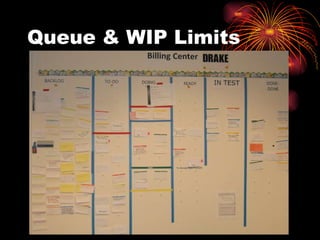

The document recounts the key insights and concepts discussed at the Lean Software and Systems Conference in Atlanta, including the importance of system thinking, minimizing waste, and making work visible. Key themes include limiting work-in-progress, optimizing flow, and ensuring delivery of value to customers. The author emphasizes that improvements in features do not necessarily correlate with better sales outcomes.

![I Went to the Lean Software and Systems Conference in Atlanta and All I Got Was a Bunch of Thought-Provoking Ideas * Ted M. Young Development Manager, BillingCenter [email_address] Guidewire Software ( http://www.guidewire.com ) *And a cool t-shirt](https://image.slidesharecdn.com/iwenttotheleansoftwareandsystemsconference-100429185656-phpapp01/75/I-went-to-the-lean-software-and-systems-conference-1-2048.jpg)