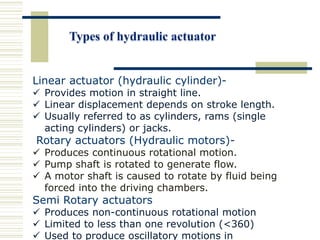

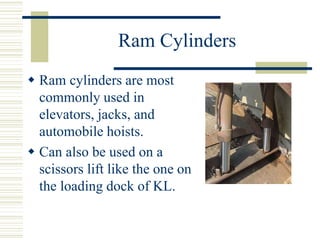

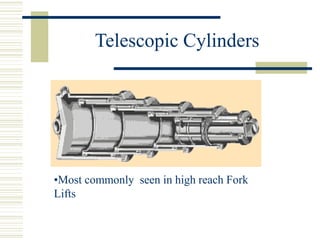

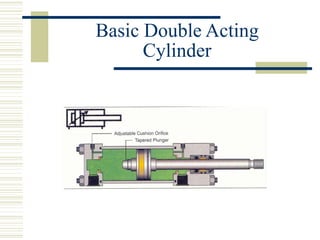

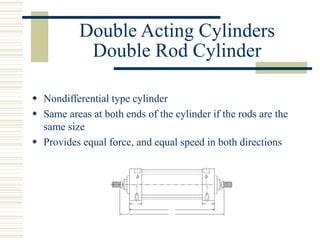

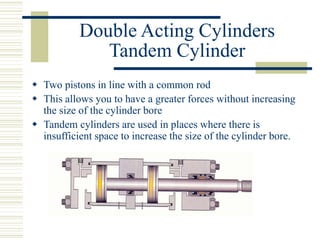

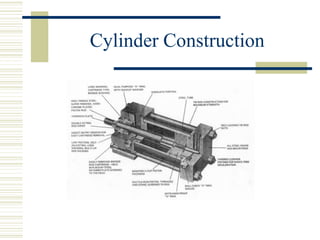

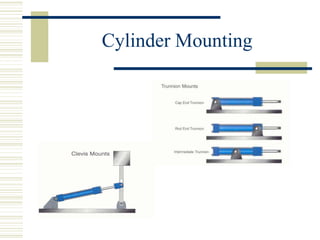

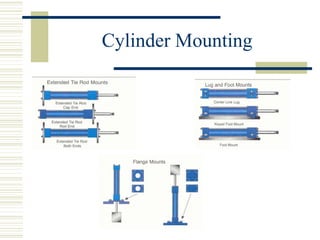

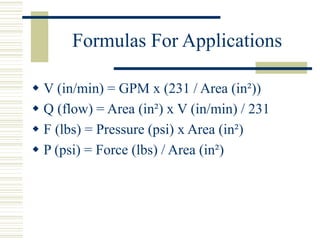

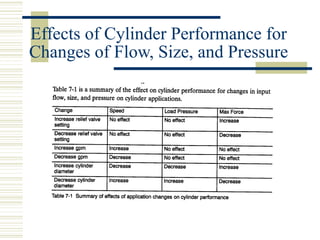

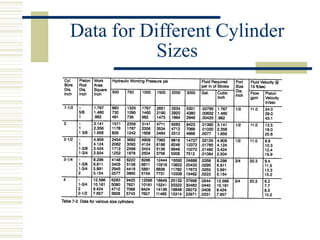

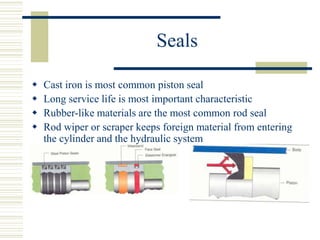

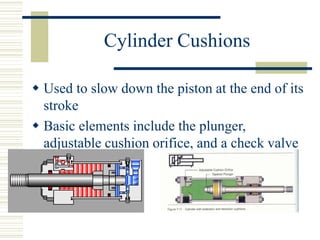

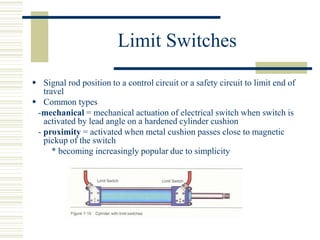

This document provides an overview of hydraulic cylinders, including their types, construction, operation, ratings, formulas for application, features, and installation/troubleshooting. It describes the main types of cylinders like ram, single acting, telescopic, spring return, and double acting cylinders. It also discusses cylinder construction, actuation, mounting, ratings based on size and pressure, formulas to calculate speed, flow, force and pressure. Key features like seals, cushions, ports and limit switches are explained. Guidelines for cylinder selection, installation and troubleshooting are provided.