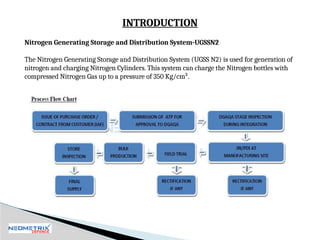

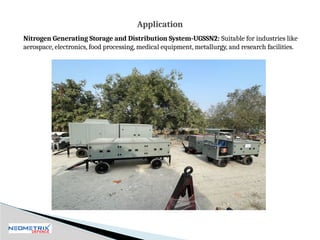

The Nitrogen Generating Storage and Distribution System (UGSS N2) is designed to generate and charge nitrogen cylinders with compressed nitrogen gas up to a pressure of 350 kg/cm2. Key components include a trailer-mounted nitrogen generation system, high-pressure storage, transportation carts, and a ground power unit, capable of producing high-purity nitrogen for various industries such as aerospace and medical equipment. The system operates under varying environmental conditions and utilizes advanced filtration and storage technology to ensure efficient nitrogen generation and distribution.