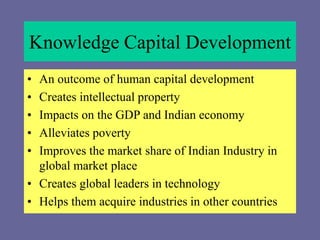

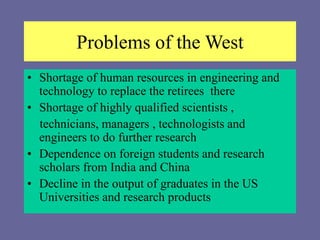

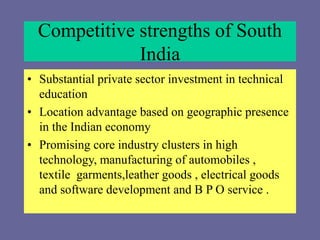

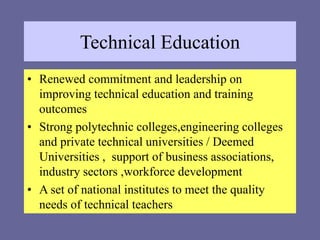

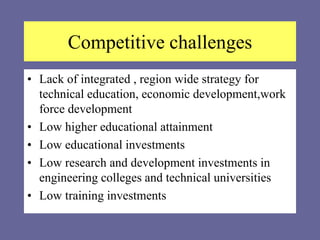

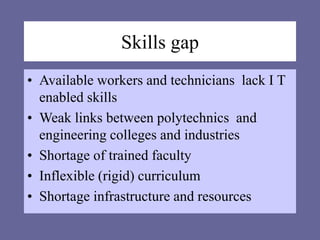

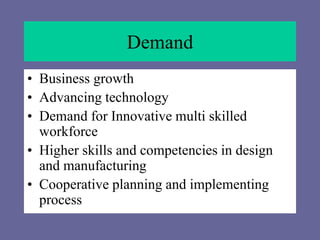

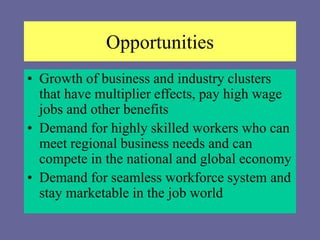

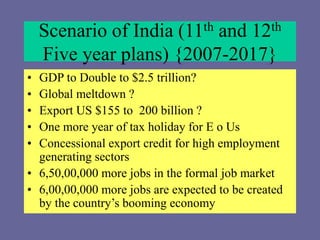

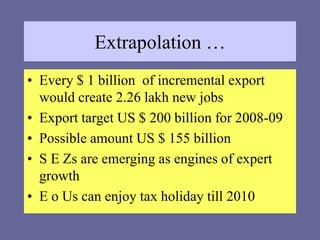

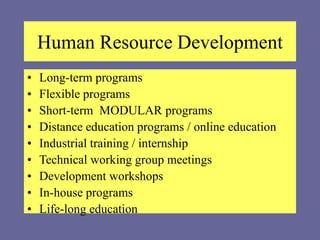

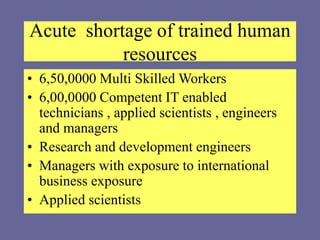

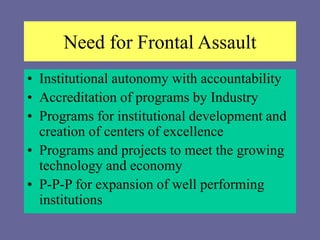

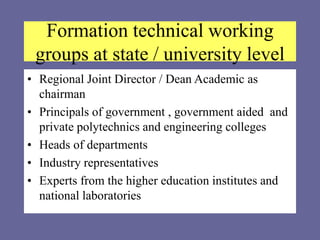

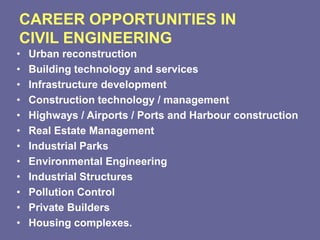

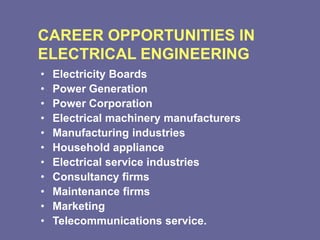

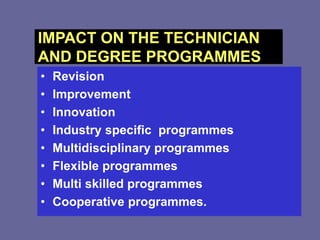

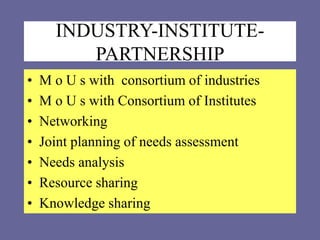

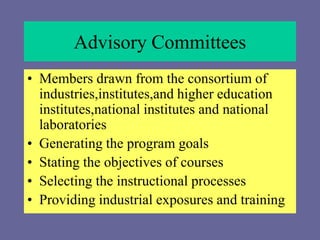

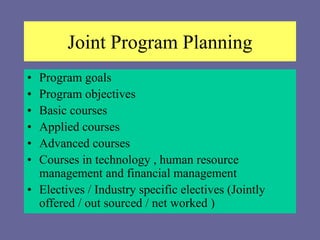

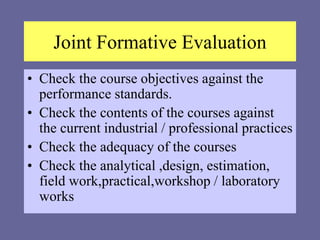

The document discusses the human resource requirements for meeting 21st-century challenges in engineering and technology in India, emphasizing the importance of human capital development for industrial advancement. It highlights issues such as the shortage of skilled workers and the need for improved technical education to enhance global competitiveness, particularly with respect to emerging opportunities and challenges from globalization. The text outlines the urgent need for strategic collaborations between educational institutions and industries to address skills gaps and foster innovation to support India's growing economy.