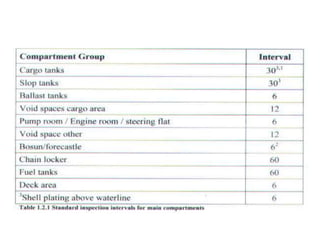

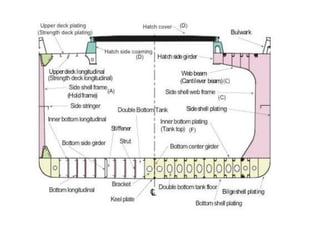

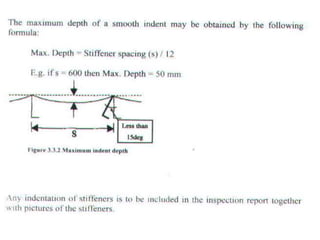

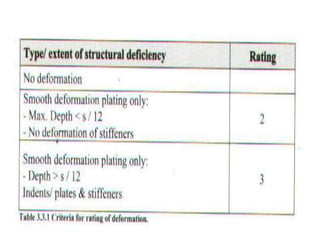

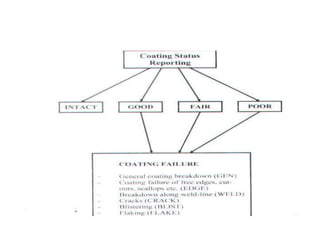

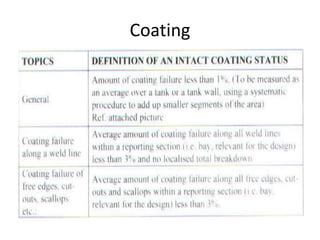

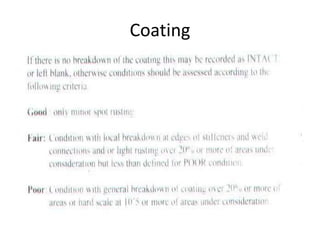

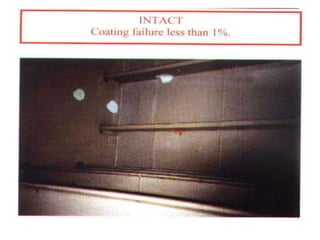

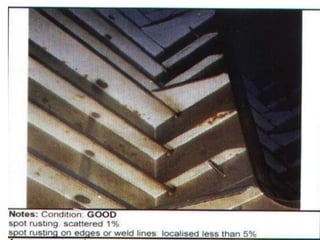

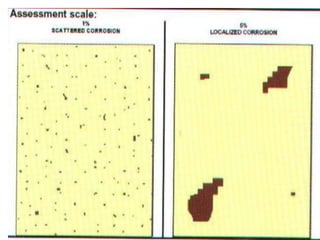

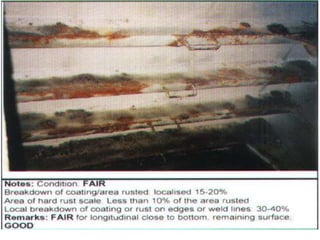

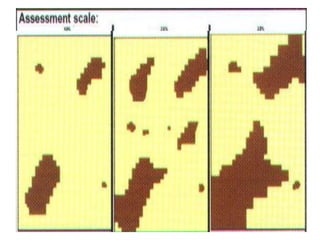

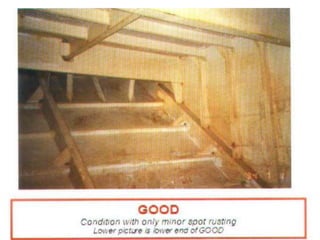

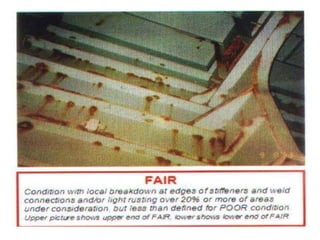

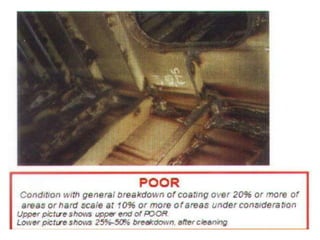

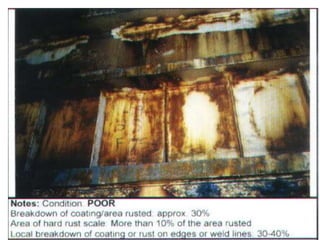

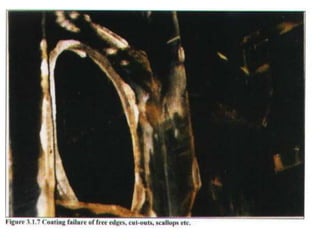

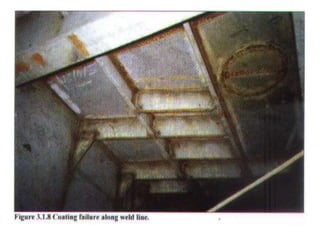

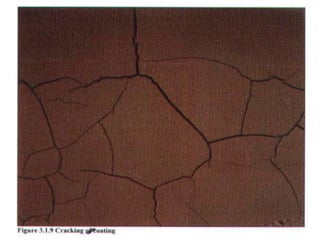

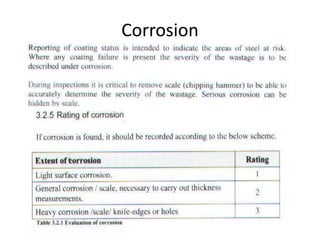

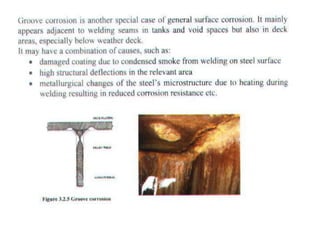

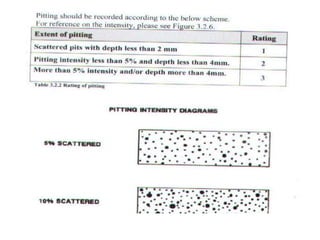

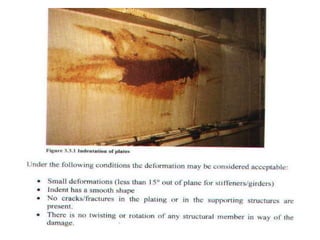

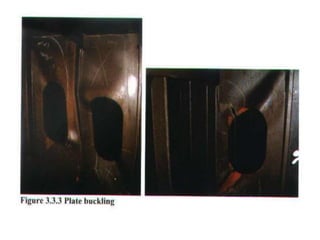

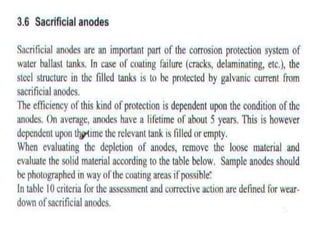

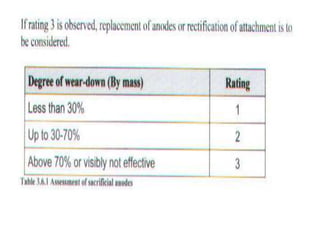

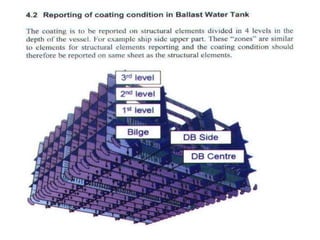

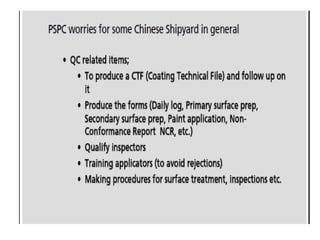

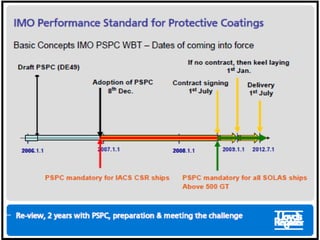

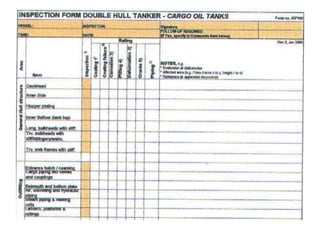

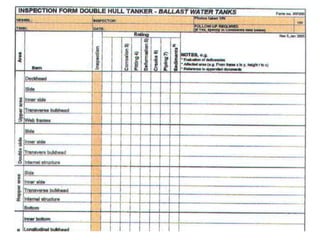

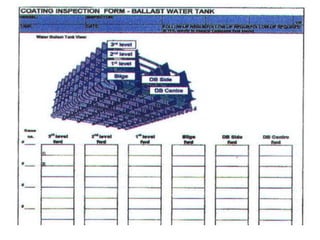

The document outlines areas and procedures for inspecting ships for defects, damages, and corrosion. It describes how to inspect different parts of the ship to check for buckling, indents, fatigue cracks, coating breakdown, and corrosion. It also discusses documenting inspection findings in reports, including what details to include for different types of defects. The purpose is to systematically check the ship's structure according to regulations and maintenance planning.